Method for testing constitutive relationship of metallic materials

A metal material, constitutive relation technology, applied in the direction of using stable tension/pressure test material strength, analysis material, measurement device, etc., can solve the problems of unpredictable hardening model, large deviation of results, low test efficiency, etc. Achieve stable and reliable calculation results, reduce consumption, and improve test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] A method for testing the constitutive relationship of metal materials, specifically comprising the steps of:

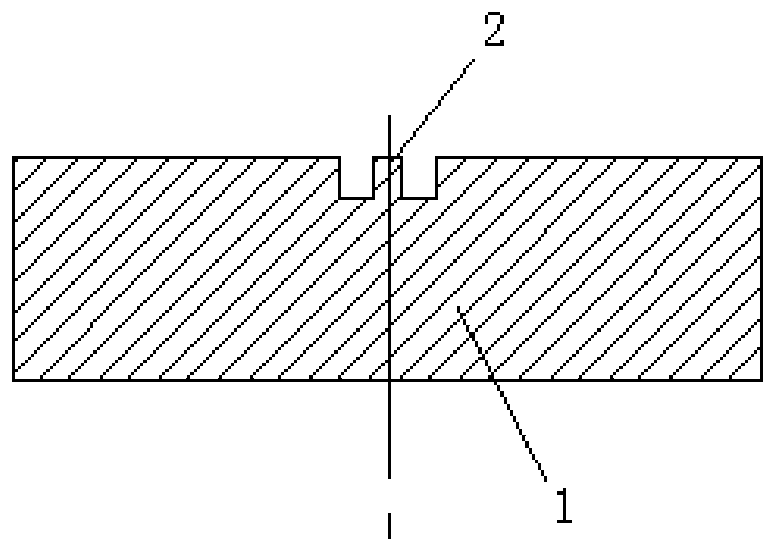

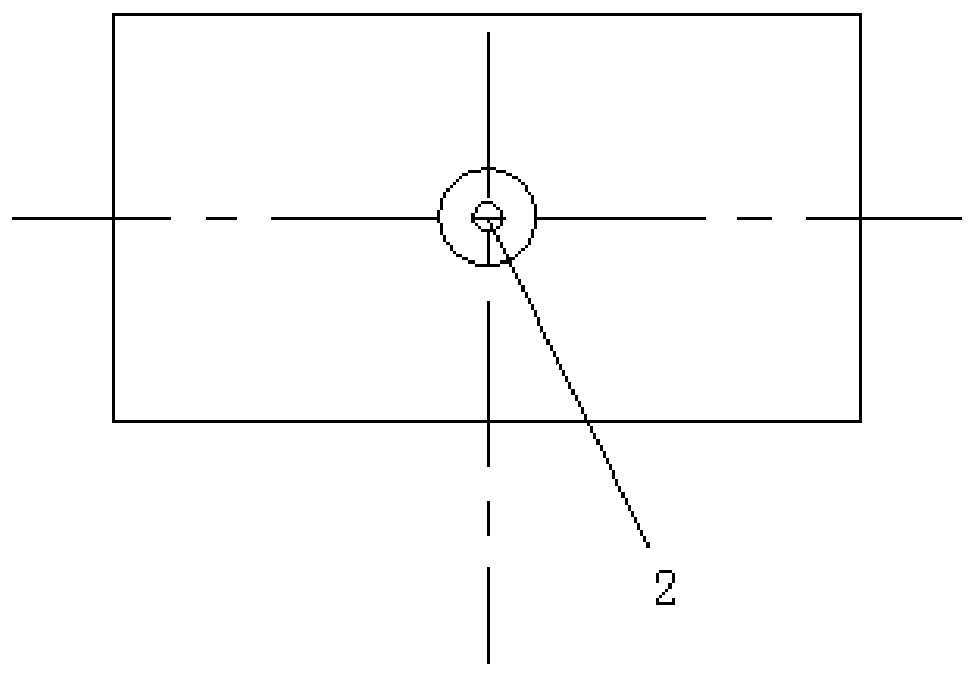

[0033] (1) The raised sample 2 is prepared by cutting, grinding or etching on the surface of the metal material 1 to be tested, referring to figure 1 , 2 , in this embodiment, the raised sample 2 is a cylinder with a height of 1.5 mm and a diameter of 1 mm;

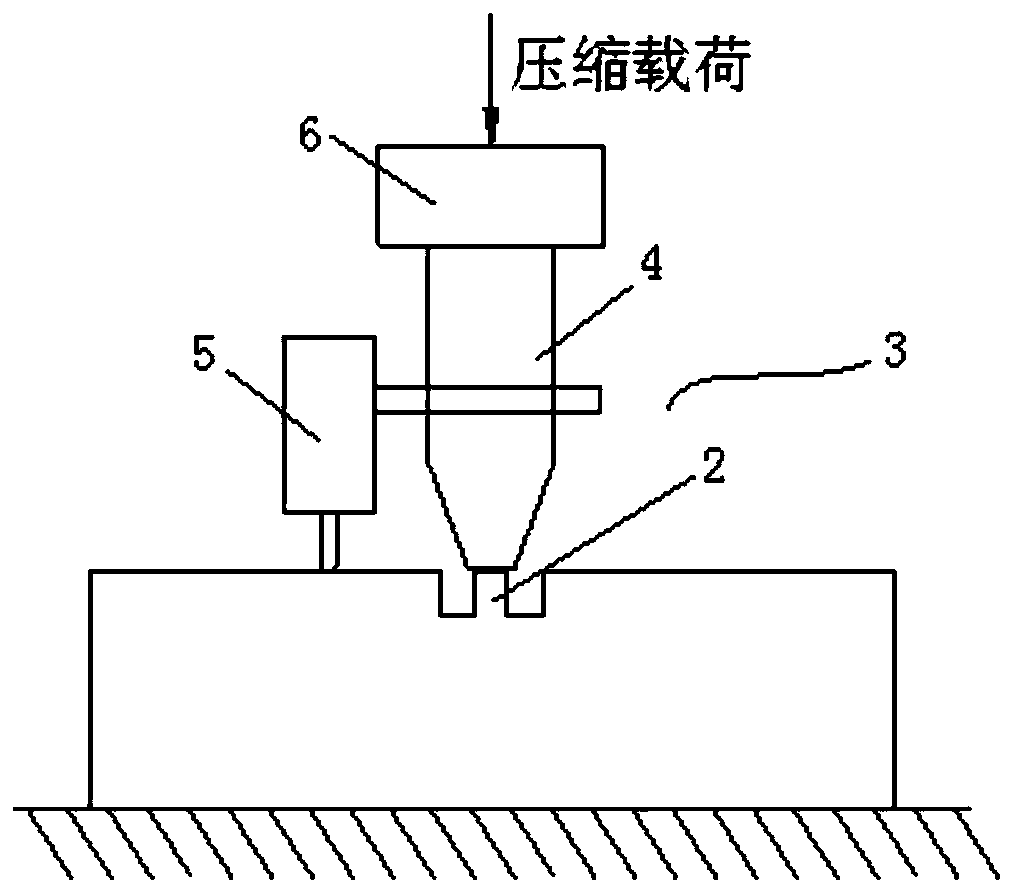

[0034] (2) Utilize the compression bar load loading mechanism 3 to carry out a compression test on the raised sample 2 to obtain a load-displacement curve; as image 3 , the pressure rod load loading mechanism 3 comprises a pressure rod 4, a load sensor 5 located at the top of the pressure rod 4 and a displacement sensor 6 at the bottom, the lower end of the pressure rod 4 is in contact with the upper end of the protruding sample 2, and the load of the pressure rod load loading mechanism 3 The sensor 6 obtains the loaded load, and the displacement sensor 5 obtains the displacement of the raised sample to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com