Device for automatically measuring hydrogen fluoride content and battery box containing device

An automatic measurement, hydrogen fluoride technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as large economic losses, and achieve the effects of high detection, high precision, and uncomplicated structure

- Summary

- Abstract

- Description

- Claims

- Application Information

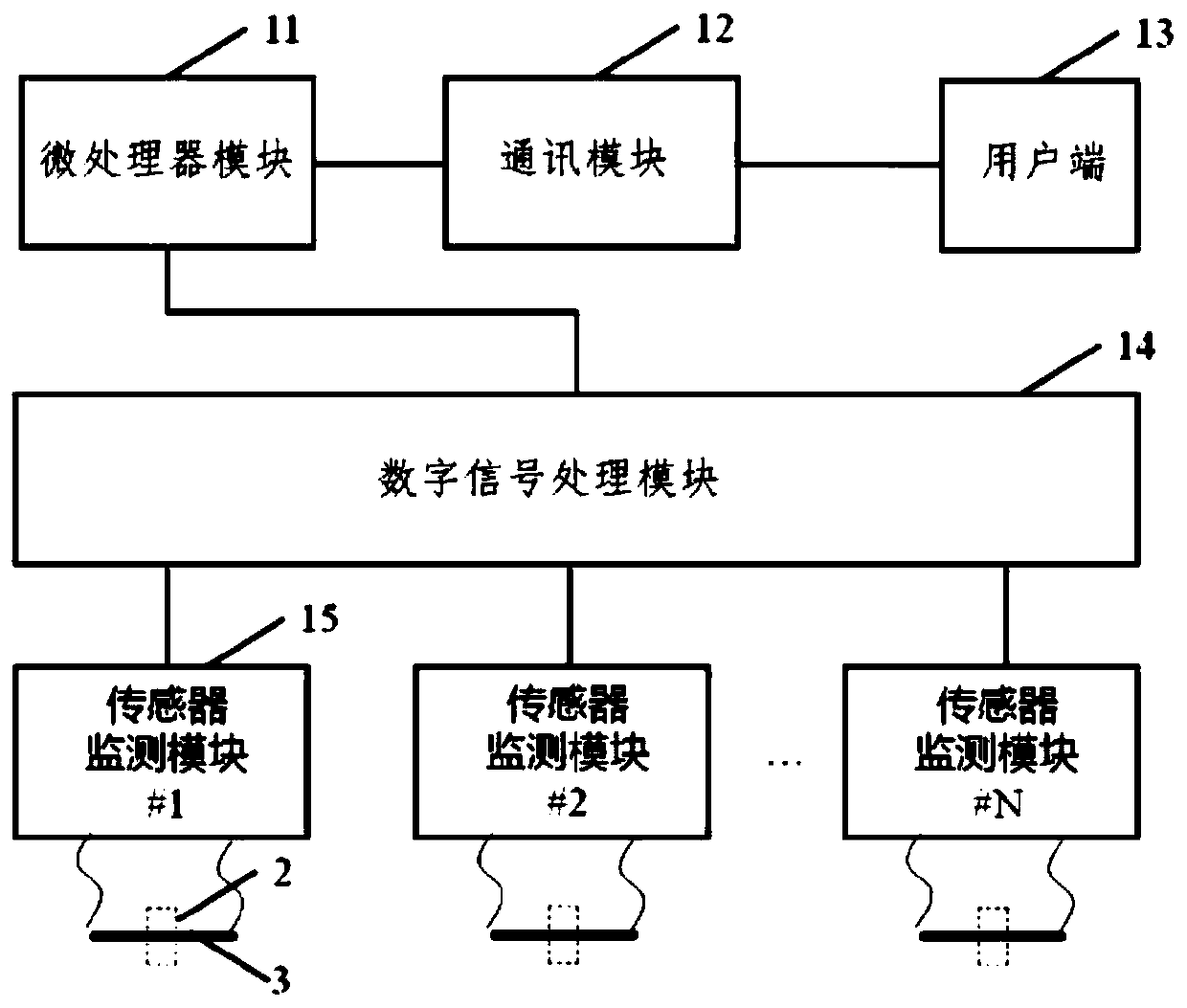

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

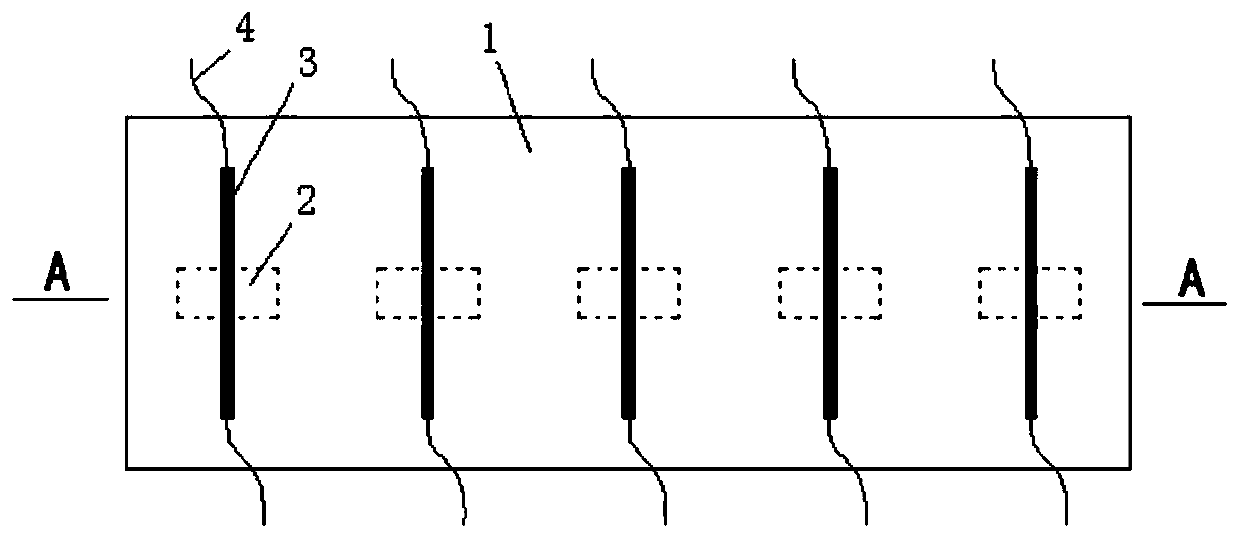

[0059] A diaphragm type device for automatically measuring the content of hydrogen fluoride. The corroded part 2 is formed by grooves on the carrier 1. Grooves of different depths correspond to corroded parts 2 of different thicknesses. The structure is simple and easy to manufacture.

[0060] Such as Figure 2a , Figure 2b with Figure 2c As shown, one side of the carrier 1 is provided with a groove, and is in contact with the gas 5 containing hydrogen fluoride, and the part between the bottom of the groove and the other side of the carrier 1 is the etched part 2 , the distance between the groove bottom of the groove and the other side of the carrier 1 is the thickness of the corroded part 2, and the conductor plating layer 3 is attached to the position corresponding to the groove on the other side of the carrier 1 place.

[0061] The carrier 1 is made of glass, and the groove is formed by picosecond laser processing or hydrofluoric acid corrosion of the carrier 1, and a ...

Embodiment 2

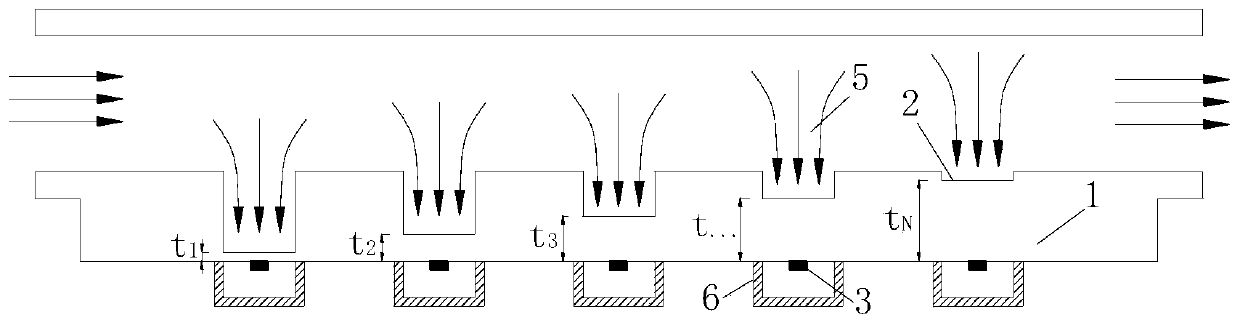

[0070] A cylindrical device for automatically measuring the content of hydrogen fluoride, the corroded part 2 is a structure similar to a cylinder arranged on the carrier 1, which is equivalent to replacing the diaphragms of different thicknesses in Example 1 with cylinders of different wall thicknesses. The cylinders represent different maximum corrosion depths.

[0071] Such as Figure 3a , Figure 3b with Figure 3c As shown, the corroded part 2 is a tubular structure with uniform thickness. One end of the tubular structure is closed and fixedly connected to the carrier 1, and the other end is sealed and fixed with a cover. gas 5 contact, the conductor coating 3 is pasted on the inner side wall of the tubular structure, and is electrically connected with the control circuit 4 through the wire passing through the tubular structure, and the side wall thickness of the tubular structure is the specified The thickness of the etched part 2 is described.

[0072] The cover cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com