Film-like heating device

A heating device and thin-film technology, which is applied in the direction of electric heating devices, heating fuel, household heating, etc., can solve the problems of insufficient performance of the heating device, brittleness of the heating device, and undiscovered materials, etc., to achieve small power supply capacity, High heating efficiency and comfortable touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

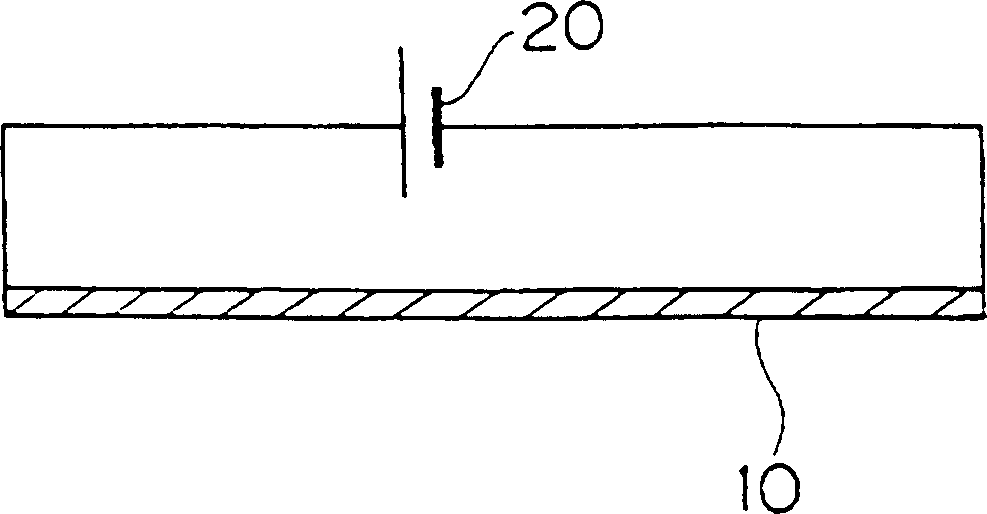

[0055] figure 1 In the shown film heating device, a DC power supply 20 is connected to both ends of a heating element 10 made of a high-crystalline graphite film through lines 22 and 22 . Also, a switch structure (not shown) for cutting off the circuit is installed in the middle of the lines 22 and 22 .

[0056] The highly crystalline graphite film 10 can be made from polyimide (DuPont, Capton H film) with a thickness of 25 μm. The graphite crystals of the highly crystalline graphite thin film 10 are oriented in the direction of the plane, and its locking property has high orientation at 20 degrees or less.

[0057] The thin film heating device of this embodiment can be assembled and used in various mechanical devices and structures. Depending on the application, the shape and pattern of the highly crystalline graphite film 10 can be freely changed.

Embodiment 2

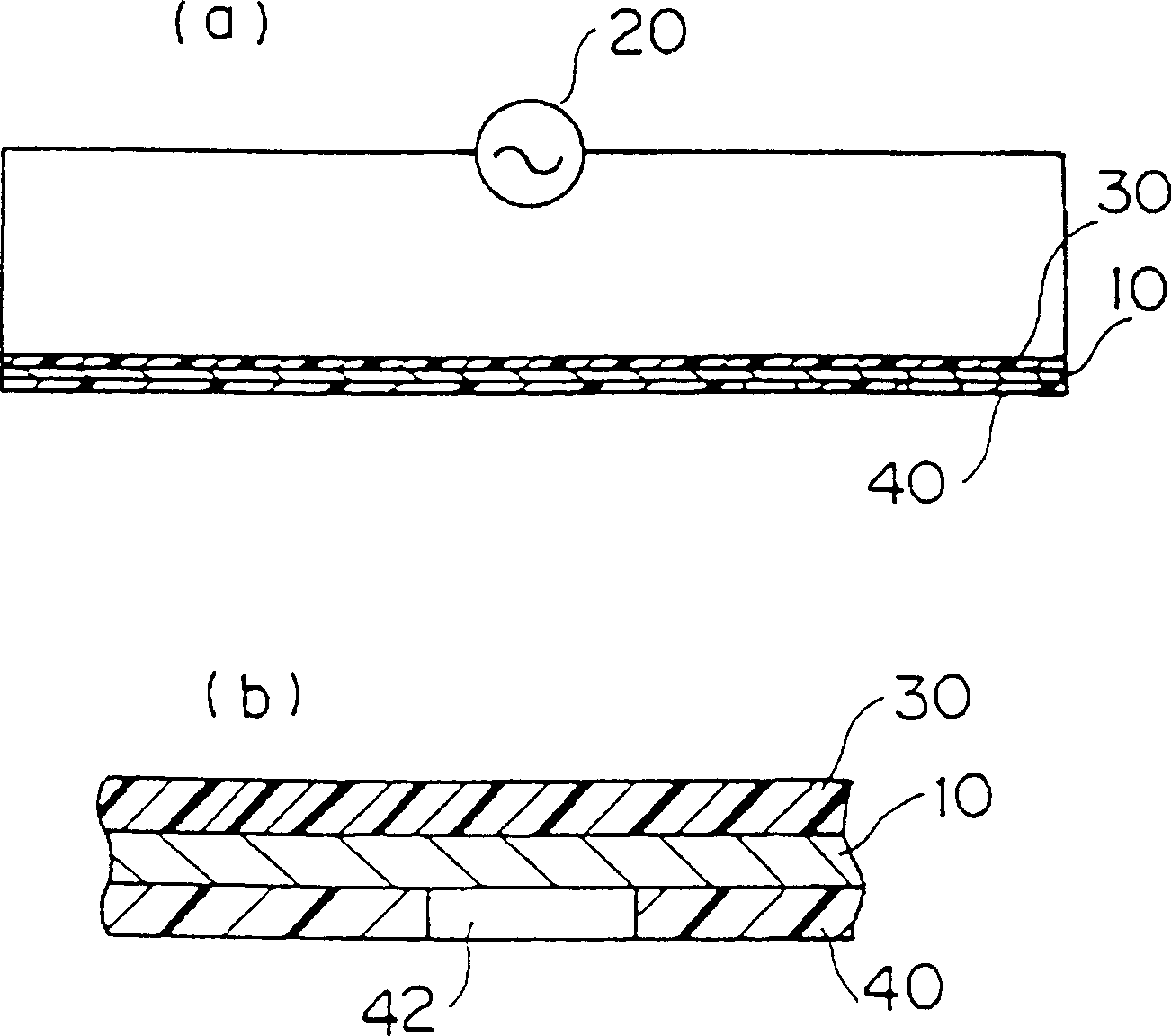

[0059] figure 2 In the film-shaped heating device shown in (a), film-shaped covering materials 30 and 40 are coated on both sides of the heating element 10 composed of the aforementioned high-crystalline graphite film. Such as figure 2 As shown in (b), the covering material 30 on one side completely covers the heat generating part 10 made of polyimide resin film. The cover material 40 on the opposite side is also made of polyimide material, and a penetration portion 42 is provided on a part of the cover material 40 .

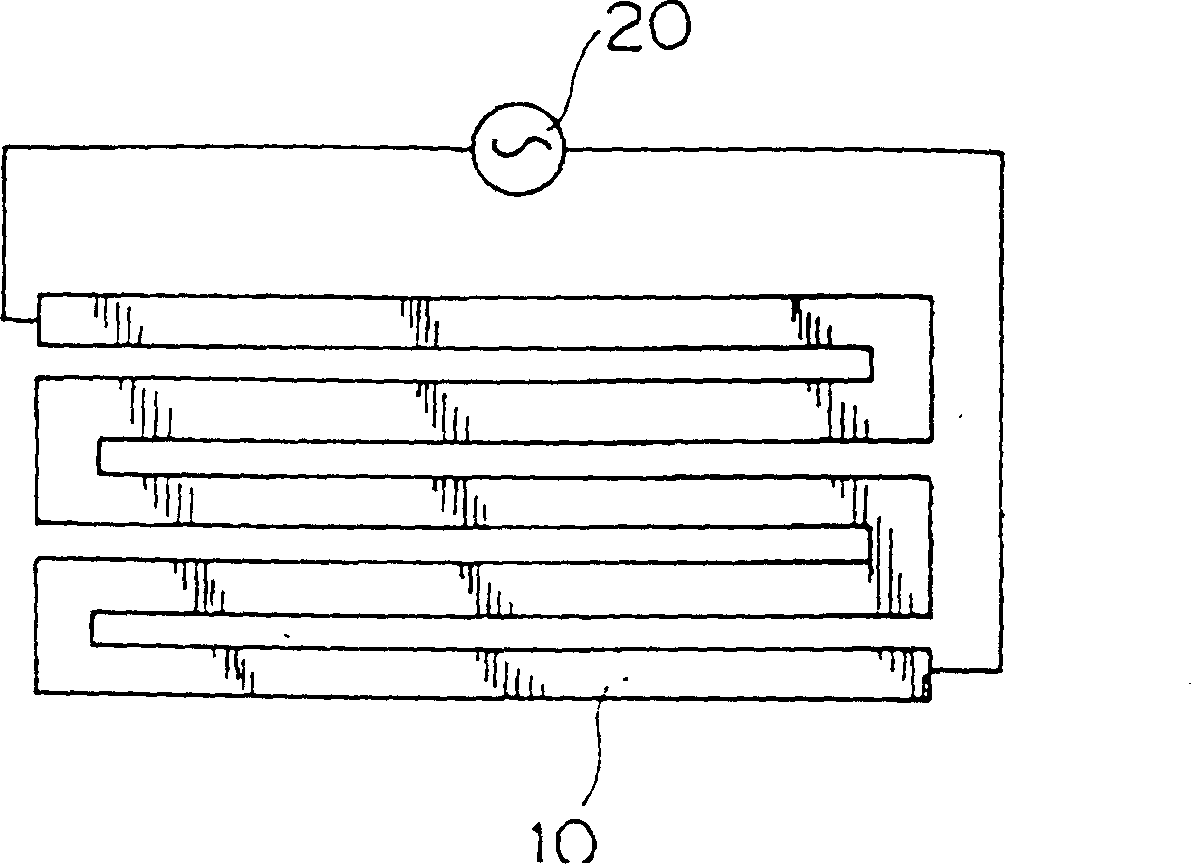

[0060] Such as image 3 As shown, the planar shape of the heat-generating component 10 is a thin strip-shaped part bent left and right. At both ends of the strip-like portion, lines 22, 22 for turning on the power source 20 are connected. The heating element 10 is obtained by cutting a planar high-crystalline graphite film.

[0061] Also, if Figure 4 As shown, a plurality of penetrating portions 42 are provided on the covering material 40 .

[0062] In...

Embodiment 4

[0070] Figure 7 The heating element 10 of the shown film heating device is composed of a plurality of strip-shaped high-crystalline graphite films 10a, 10b to form an S-shape as a whole. In this way, the entire heat generating component 10 can also be formed by combining a plurality of diaphragms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com