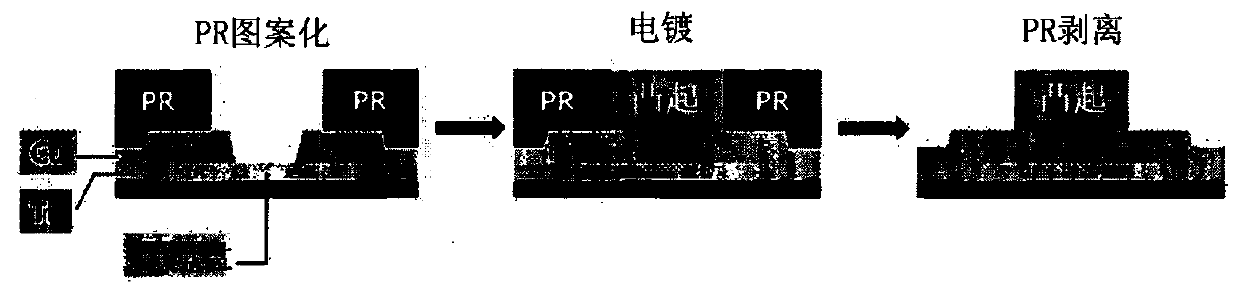

Positive type photoresist composition, pattern manufactured therefrom, and method for manufacturing pattern

A technology of photoresist and composition, which is applied in the direction of photosensitive materials, optics, and photomechanical equipment used in photomechanical equipment, and can solve the problems of reduced thermal stability of photoresist compositions, raised impurities, Resin incompatibility and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] 40 g of m-, p-cresol novolac resin (Mw: 12000, ADR) represented by the following chemical formula 6 as a binder resin / sec), 50 g of an acrylic resin represented by the following chemical formula 8 (Mw: 65000), 10 g of an oligomer compound of the following chemical formula 9 having a functional group protected by an acetal group as an oligomer compound (Mw: 1500) , 3g of N-(trifluoromethylsulfonyloxy)-1,8-naphthalimide as a photoacid generator and 0.1g of trihydroxyethylamine as a quencher were mixed, and then at room temperature Stir to make a homogeneous solution. Thus, a positive photoresist composition was produced.

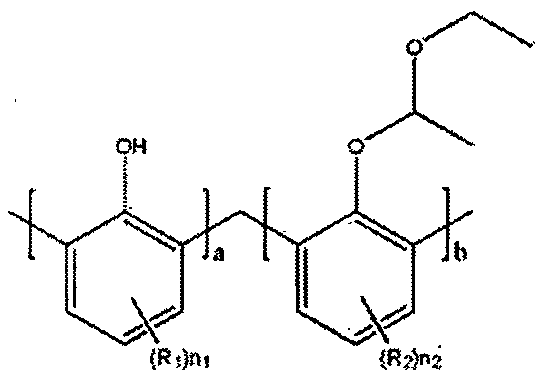

[0154] [chemical formula 6]

[0155]

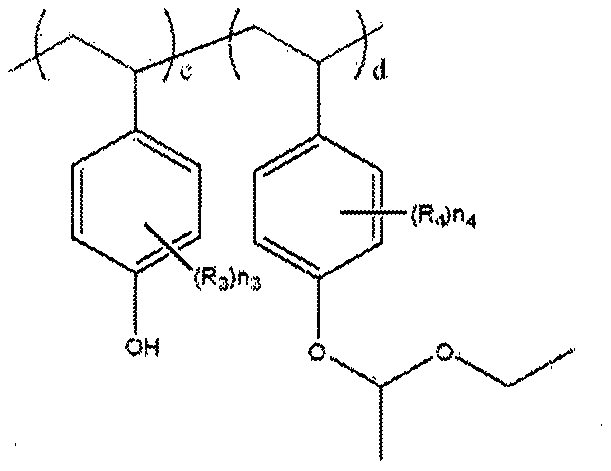

[0156] [chemical formula 8]

[0157]

[0158] [chemical formula 9]

[0159]

Embodiment 2

[0161] A positive photoresist composition was produced in the same manner as in Example 1 except that an oligomer compound (Mw: 2500) represented by Chemical Formula 11 was used as a dissolution inhibitor.

[0162] [chemical formula 11]

[0163]

Embodiment 3

[0165] A positive photoresist composition was produced in the same manner as in Example 1, except that 10 g of m-,p-cresol novolac resin (Mw: 12000, ADR / sec), 30 g of acetal-protected polyhydroxystyrene resin represented by the following chemical formula 7 (Mw: 15300, substitution rate: 25%), and 50 g of an acrylic resin represented by the following chemical formula 8 (Mw: 65000).

[0166] [chemical formula 6]

[0167]

[0168] [chemical formula 7]

[0169]

[0170] [chemical formula 8]

[0171]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com