A kind of hierarchical porous zsm-5 nano-aggregate microsphere and its preparation method

A ZSM-5 and aggregate technology, applied in the field of preparation of ZSM-5 microspheres, can solve the problems of complex molecular sieve production process, large molecular diffusion resistance, difficult separation, etc., and achieve easy separation of products, improved diffusion capacity, and cheap raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

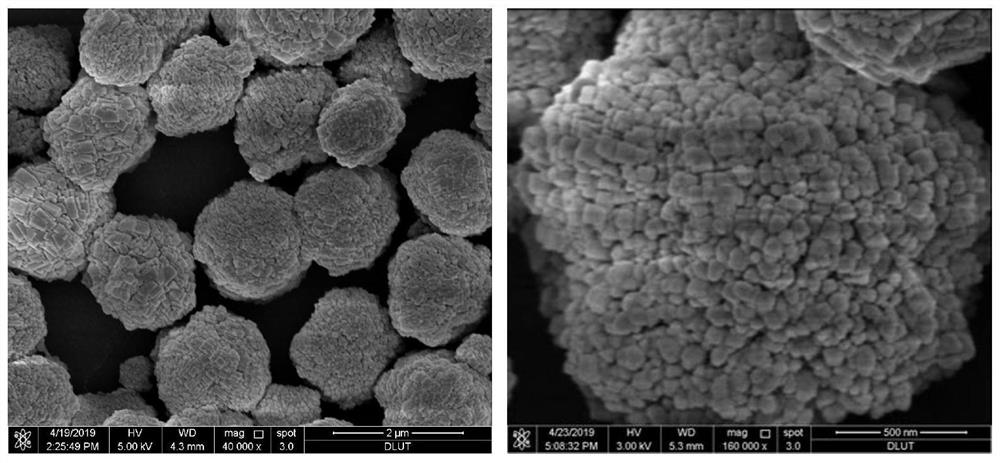

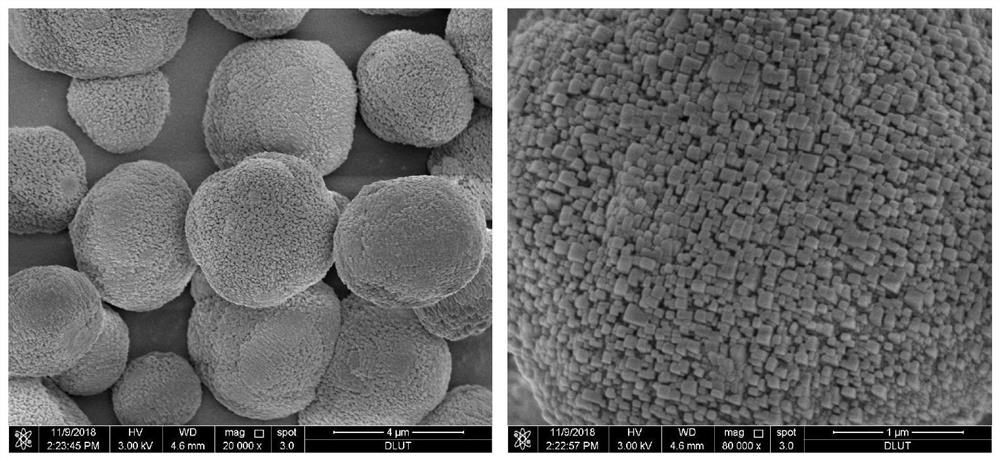

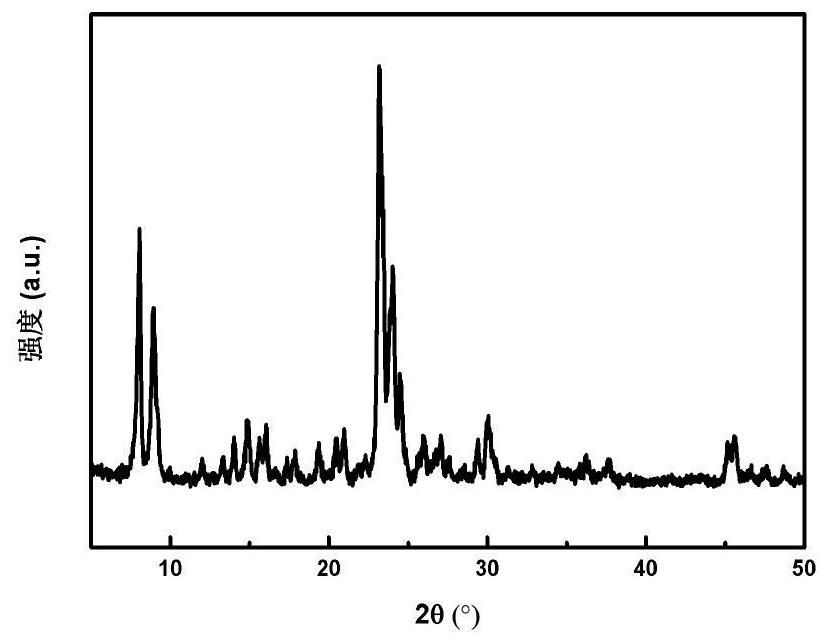

Embodiment 1

[0030]Alkali source: silicon source: aluminum source: template: bioalcohol: deionized water = 10:100:3:10:20:2000 in molar ratio, dissolve 0.89g sodium metaaluminate in 10.35g TPAOH solution, add 2.33mL A 10mol / L NaOH solution has been prepared, then 2.00mL of water is added, and stirred for half an hour to form a uniform, clear and transparent solution. Finally, 24g of silica sol is slowly added dropwise to the above solution. After rapid stirring for 3h, 1.7mL of bioglycerin is added. Continue to stir for 1 hour, then transfer to a hydrothermal synthesis kettle with PTFE lining, and place it in a 170°C oven for crystallization for 1 day. After the crystallization is completed, the upper alkaline clear liquid is poured out, and the lower solid product is washed with water to neutrality, dried, and calcined to finally obtain multi-porous ZSM-5 nano aggregate microspheres. The final product yield reached 91.2%, the size of the microspheres was about 2um, and the size of the nanocryst...

Embodiment 2

[0032]The steps for preparing the multi-stage porous ZSM-5 nano-aggregate in this example are basically the same as those in Example 1, with the only difference being the ratio of silicon to aluminum. Alkali source: silicon source: aluminum source: templating agent: bioalcohol: deionized water = 10:100:1:10:20:2000 in molar ratio, 0.27g sodium metaaluminate dissolved in 10.35g TPAOH solution, add 2.33mL A 10mol / L NaOH solution has been prepared, then 2.00mL of water is added, and stirred for half an hour to form a uniform, clear and transparent solution. Finally, 24g of silica sol is slowly added dropwise to the above solution. After rapid stirring for 3h, 1.7mL of bioglycerin is added. Continue to stir for 1 hour, then transfer to a hydrothermal synthesis kettle with PTFE lining, and place it in a 170°C oven for crystallization for 1 day. After the crystallization is completed, the upper alkaline clear liquid is poured out, and the lower solid product is washed with water to neutra...

Embodiment 3

[0034]In this example, the steps for preparing the multi-stage porous ZSM-5 nano-aggregate are basically the same as those in Example 1, except that the amount of glycerin added is different. Alkali source: silicon source: aluminum source: templating agent: bioalcohol: deionized water = 10:100:3:10:40:2000 in molar ratio, dissolve 0.89g sodium metaaluminate in 10.35g TPAOH solution, add 2.33mL A solution with a concentration of 10mol / L NaOH has been prepared, and then 2.00mL of water is added, and stirred for half an hour to form a uniform, clear and transparent solution. Finally, 24g of silica sol is slowly added dropwise to the above solution, after rapid stirring for 3h, 3.4mL of bioglycerin is added, and continue After stirring for 1 hour, it was transferred to a hydrothermal synthesis kettle with polytetrafluoroethylene lining, sealed and placed in a 170°C oven for crystallization for 1 day. After the crystallization is completed, the upper alkaline clear liquid is poured out, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com