Skeleton-wrapping electrothermal functional ceramic, and preparation method and application method thereof

A functional ceramic and packaged technology, which is applied in applications, electric heating devices, clay products, etc., can solve the problem of low utilization rate of electric heating, and achieve the effects of high utilization rate of electric heating, strong safety, and low heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

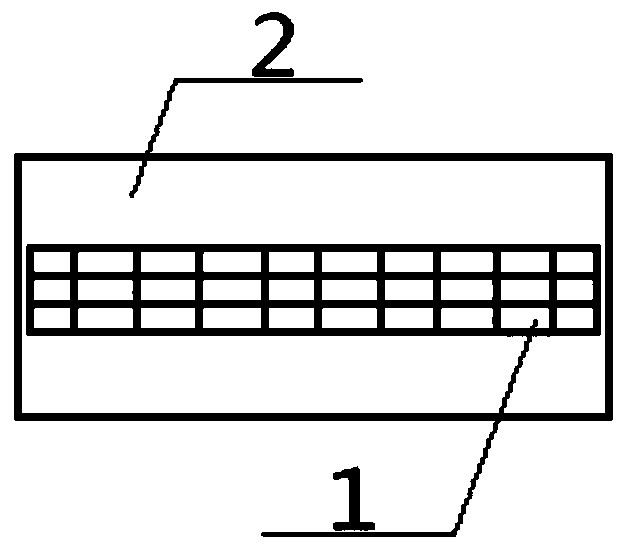

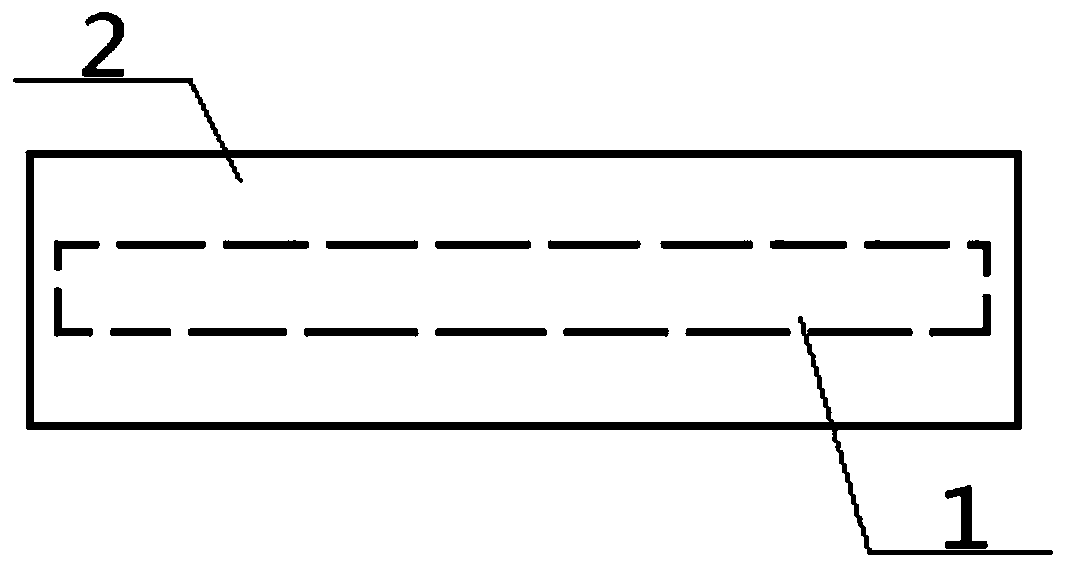

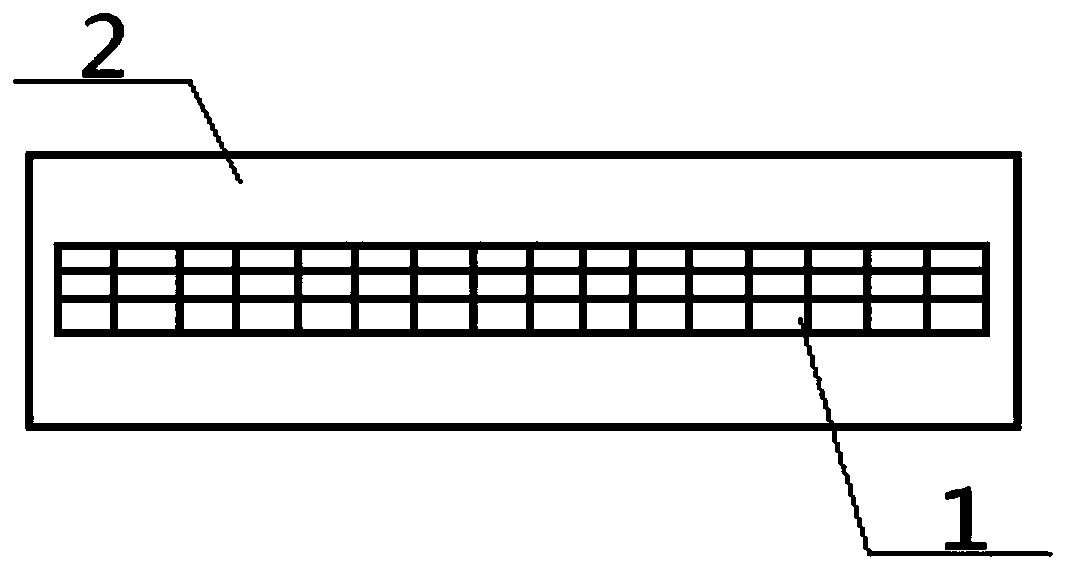

[0062] see figure 1 - image 3 , a method for preparing skeleton-wrapped electric heating functional ceramics, comprising the following steps: first weaving single fibers to obtain fabrics, then cutting, stacking and sewing the fabrics to obtain a three-layer stacked blank core skeleton 1, and then The blank core skeleton 1 is wrapped in the ceramic precursor 2, and then pressed and formed at a pressure of 20-100 MPa, then dried to obtain a molded body, and then the molded body is sent into a ceramic kiln, and then the molded body is subjected to oxygen barrier conditions. The sintering is carried out at 1100° C. and the sintering time is 2 hours to obtain the electrothermal functional ceramics.

[0063] Described single fiber is any one in polyacrylonitrile fiber, cellulose fiber, protein fiber, pitch fiber, resin fiber; The manufacturing material of described ceramic precursor 2 is ceramic mud, ceramic powder or the mixture of both, so The ceramic mud is a muddy mixture fo...

Embodiment 2

[0065] Basic content is the same as embodiment 1, the difference is:

[0066] The single fiber is the single fiber after pre-oxidation, the pre-oxidation temperature is 200°C, and the pre-oxidation time is 4 hours; the composition and weight ratio of the ceramic powder are: silicon dioxide 40, trioxide Aluminum 30, remaining material 15; the sintering temperature is 1000°C, and the sintering time is 3h.

Embodiment 3

[0068] Basic content is the same as embodiment 1, the difference is:

[0069] The fabric is the fabric after pre-oxidation, the pre-oxidation temperature is 350°C, and the pre-oxidation time is 4 hours; the composition and weight ratio of the ceramic powder are: silicon dioxide 40, aluminum oxide 10 , Remaining material 20, sintering temperature is 1200 ℃, sintering time is 2.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com