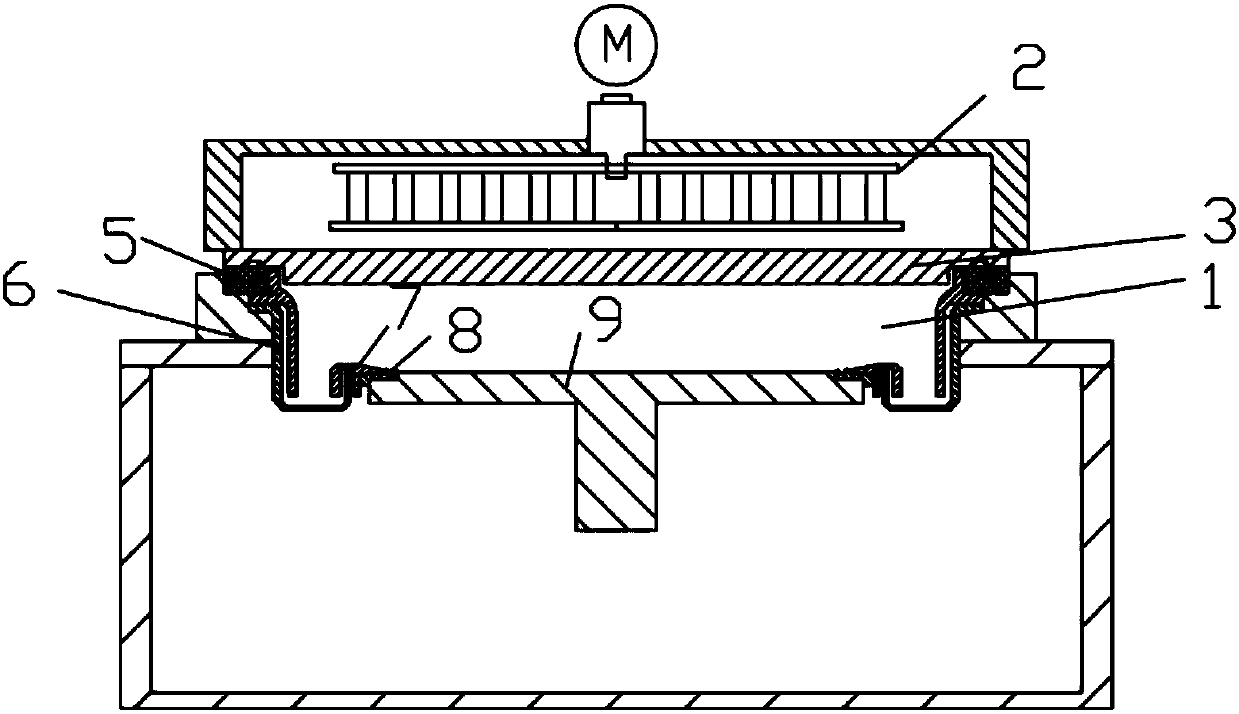

Kit and reaction chamber

A reaction chamber and process technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of poor particle control effect, insufficient roughness, large damage to the process kit, etc., to improve the service life , the effect of increasing roughness and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order for those skilled in the art to better understand the technical solution of the present invention, the process kit and the reaction chamber provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0041] The surface of the process kit provided by the present invention is provided with a textured structure, and the pattern structure is used to increase the roughness of the surface of the process kit so as to control particles.

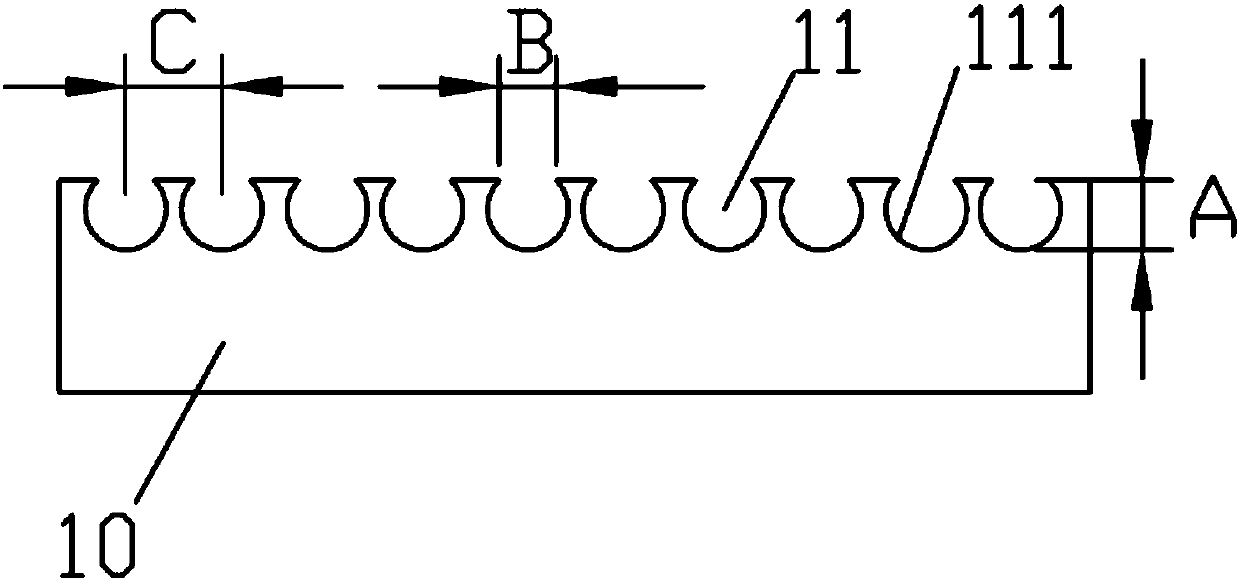

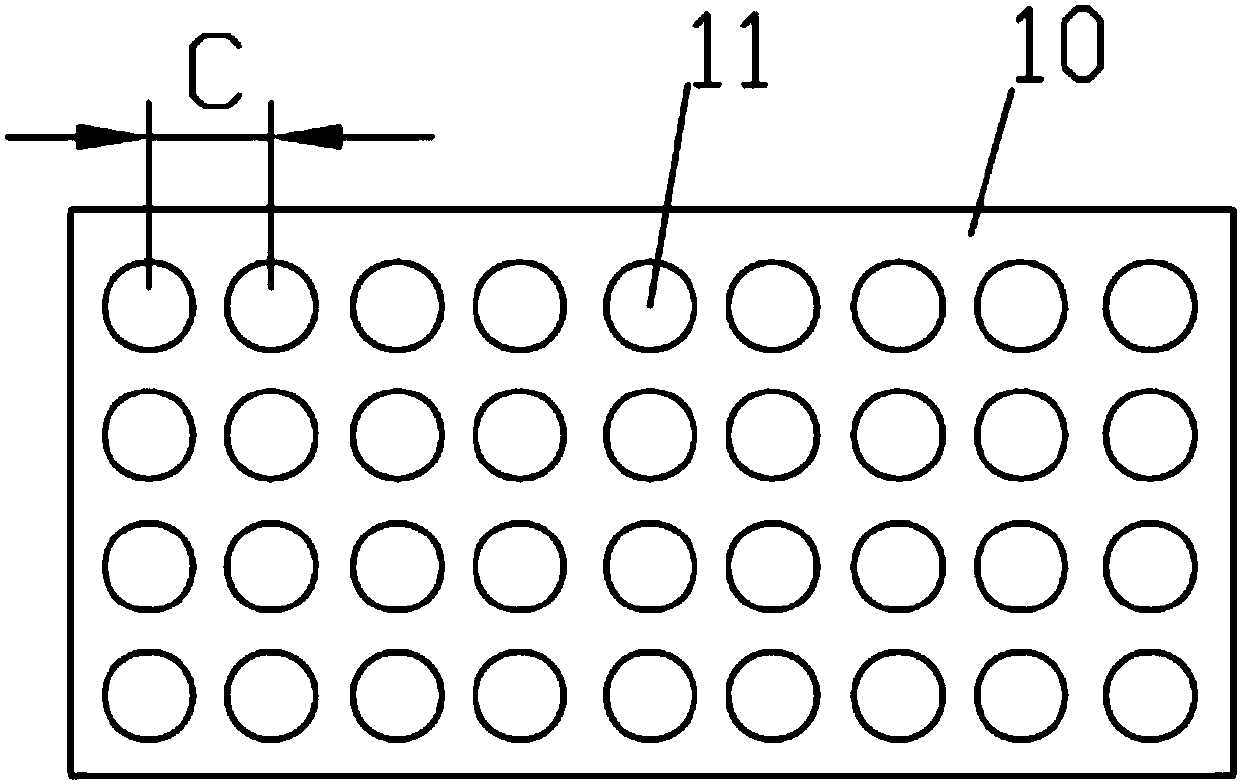

[0042] Please also refer to Figure 2A to Figure 2B , in the process kit provided in the first embodiment of the present invention, the textured structure 10 includes a plurality of recesses 11 , and each recess 11 includes a spherical concave surface 111 .

[0043] The roughness of the surface of the process kit can be increased by means of multiple recesses 11 , and the roughness of this structure can reach Ra40-60. At the same time, with the help of the spherical concave surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com