Packaging method of solid-state battery

A solid-state battery and packaging method technology, applied in battery assembly, secondary battery manufacturing, non-aqueous electrolyte storage batteries, etc., can solve problems such as module PACK assembly difficulties, achieve a good installation environment, improve efficiency, improve packaging effects and The effect of packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Steel plastic film, its preparation method comprises the steps:

[0042] a. Take SPCE low-carbon steel foil with a thickness of 18 μm, clean its surface with alcohol with a concentration of 92%, and then dry the cleaned SPCE low-carbon steel foil with a hot air blower, and place it for cooling after drying 4min;

[0043] b. Pre-plate a layer of ultra-thin nickel layer on both sides of the surface of SPCE low-carbon steel foil by pulse electroplating process as the iron-nickel bonding layer, and then use DC electroplating process to electroplate a layer thickness on the two outer surfaces of the iron-nickel bonding layer A dull nickel layer of 0.8 μm is used, and then a dark nickel layer with a thickness of 0.4 μm is electroplated on both outer surfaces of the dumb nickel layer by a pulse electroplating process, thereby forming a steel shell 1;

[0044] c. Clean the steel shell 1 with clean water, then dry it with a hot air blower, and let it cool for 7 minutes after dr...

Embodiment 1

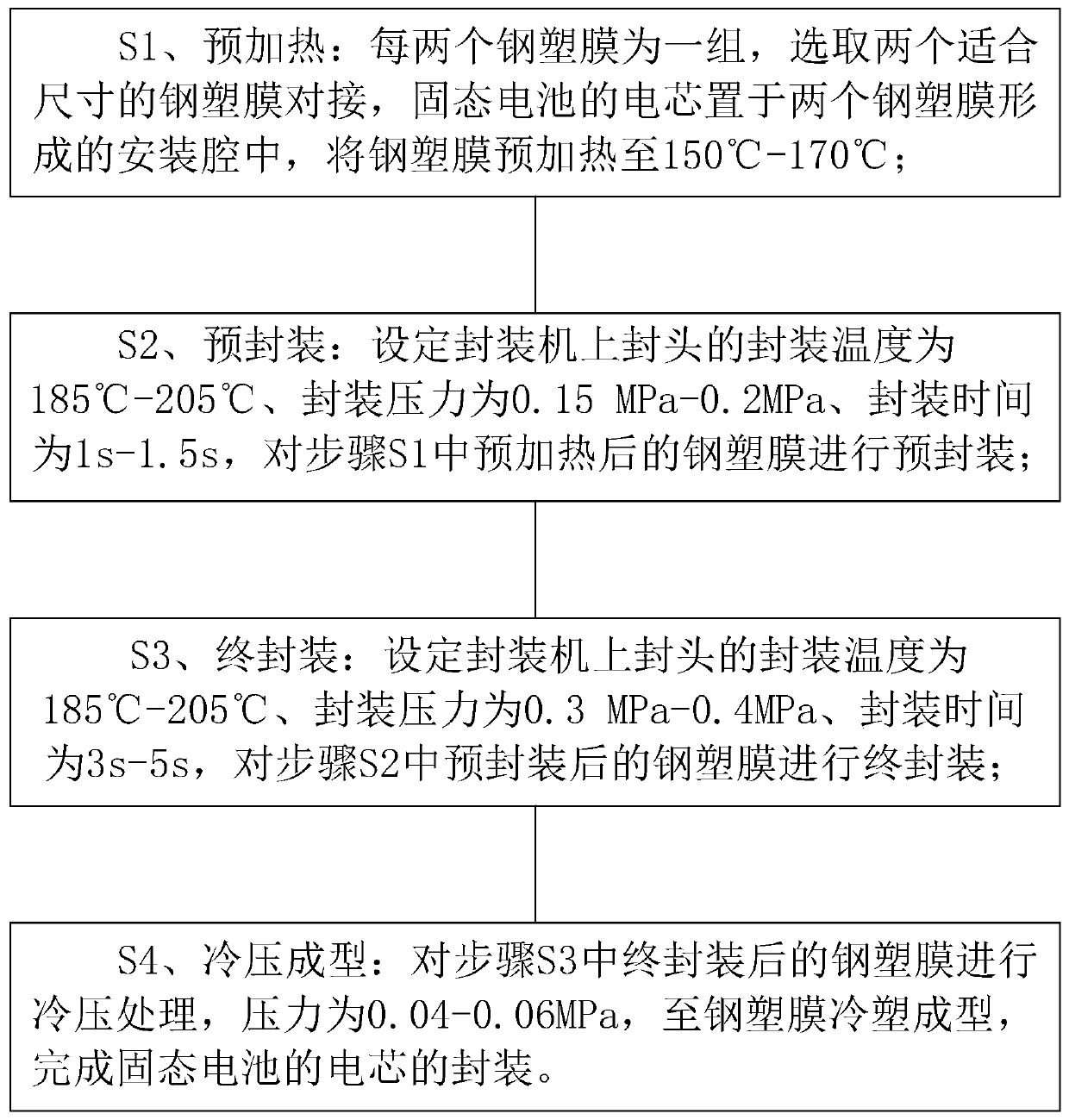

[0053] A packaging method for a solid-state battery, comprising the following steps:

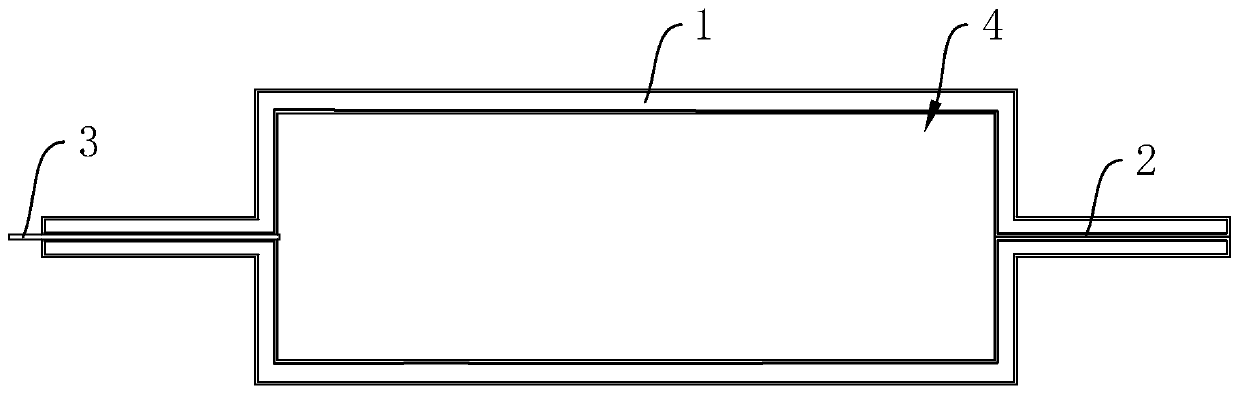

[0054] S1. Preheating: Select the steel-plastic film of the above size, soak it in the degreasing agent for 15 minutes, take it out, wash it twice with clean water in the spray room, and dry it in an oven at 80°C. Two steel-plastic films are a group, and two of them are selected for docking. The battery cell of the solid-state battery is placed in the installation cavity 4 formed by the two steel-plastic films. During the docking process, the exhaust pipe 3 is clamped to the two steel Between the plastic films, one end of the exhaust pipe 3 is extended into the installation cavity 4, and the steel-plastic film is preheated by infrared heating, wherein each time the infrared ray is irradiated for 20s and then pauses for 10s, this cycle is repeated 8 times, preheated to 150°C, the PP layer 2 of the steel-plastic film melts.

[0055] S2. Pre-packaging: Set the sealing temperature of the sealin...

Embodiment 2-5

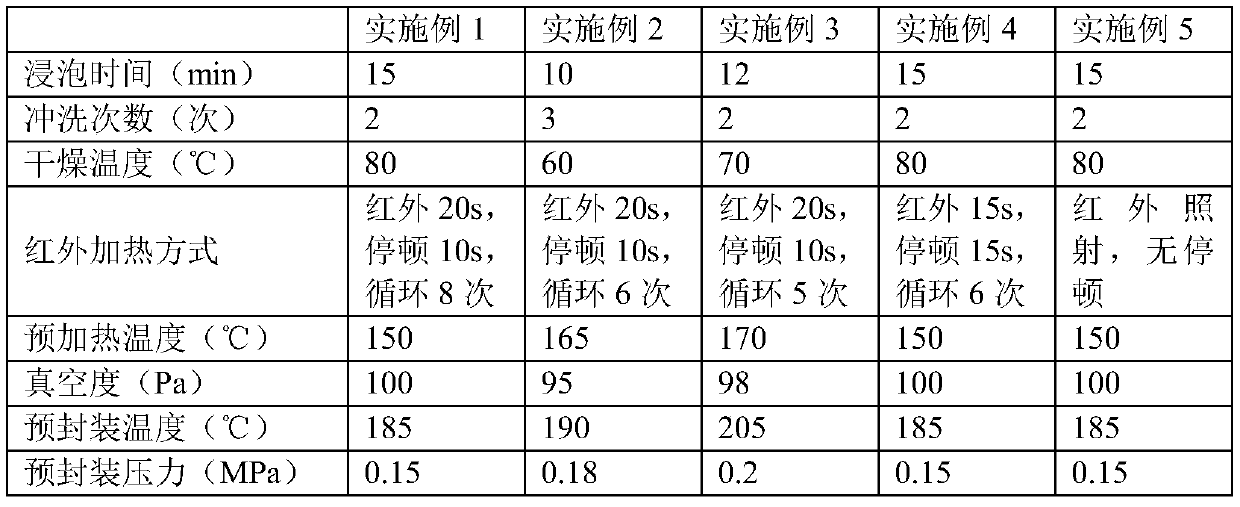

[0059] Embodiments 2-5 adjust the parameters in the encapsulation process on the basis of the method in Embodiment 1. For specific adjustments, see Table 1 below.

[0060] The encapsulation parameter of table 1 embodiment 1-5

[0061]

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com