Heating device used in vacuum device

A heating device and vacuum equipment technology, applied in the direction of heating element shape, ohmic resistance heating parts, etc., can solve the problems of serious thermal electron radiation, slow heating rate, large heating table, etc., to achieve fast heating rate and high working temperature High, precise temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

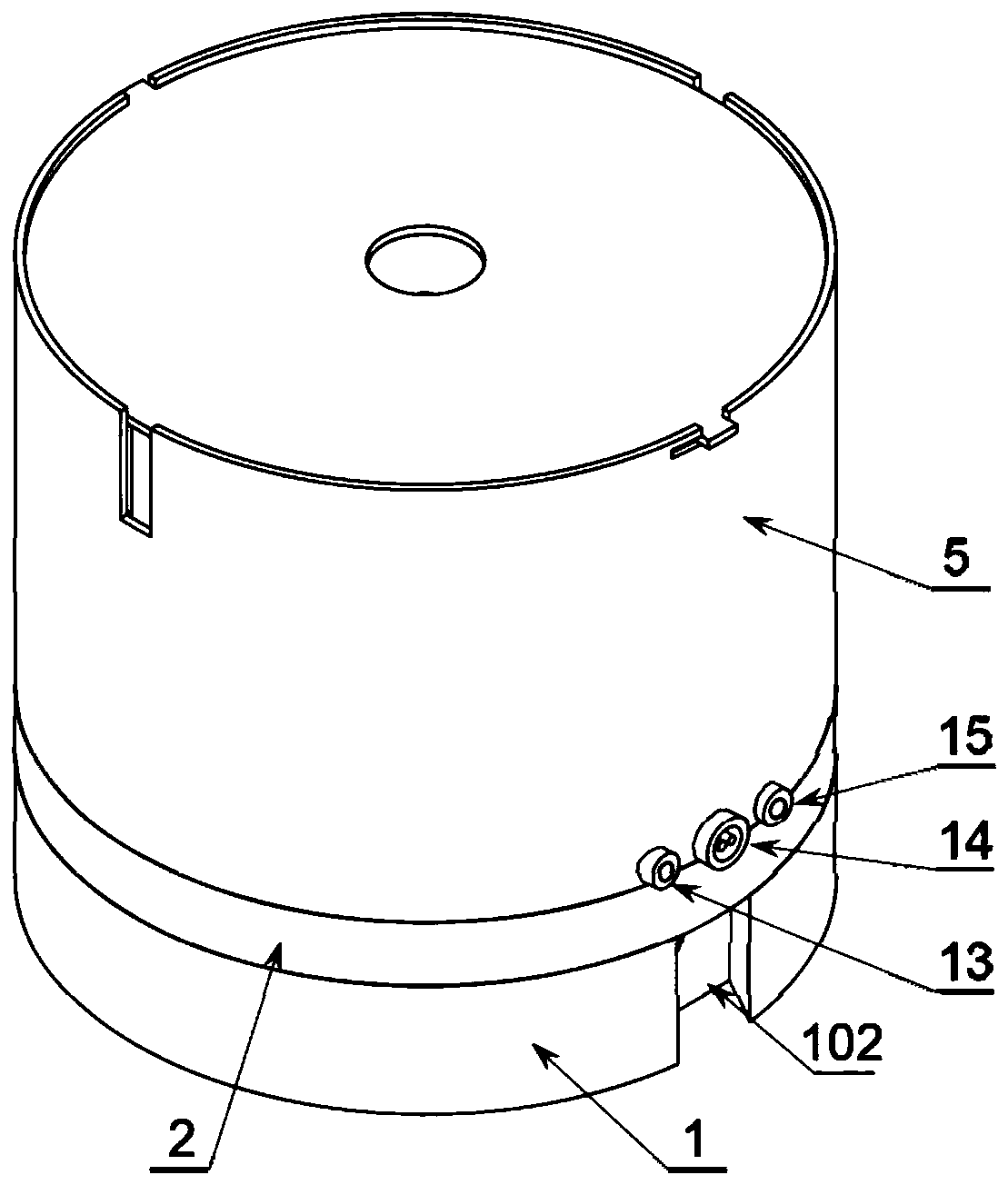

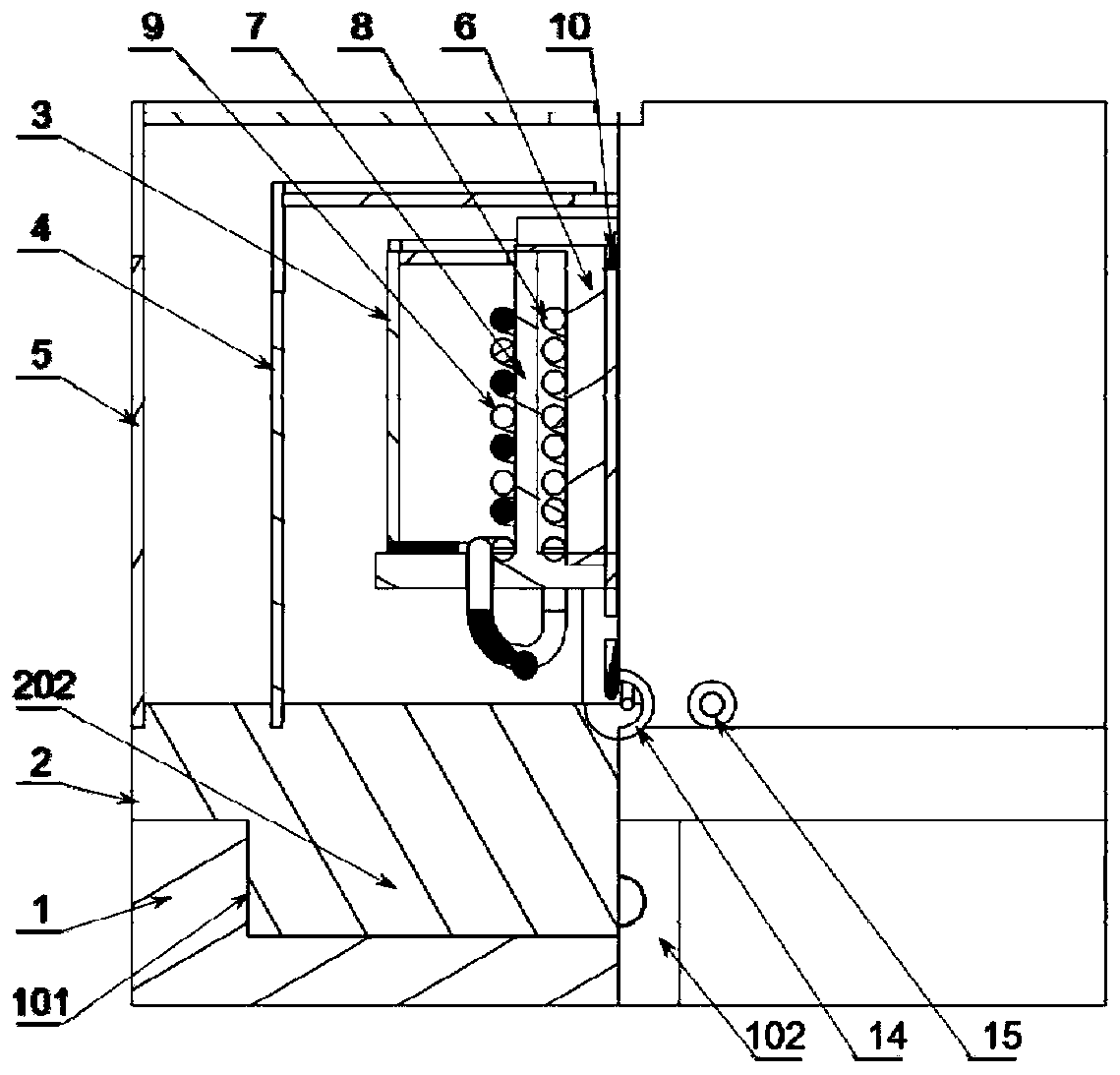

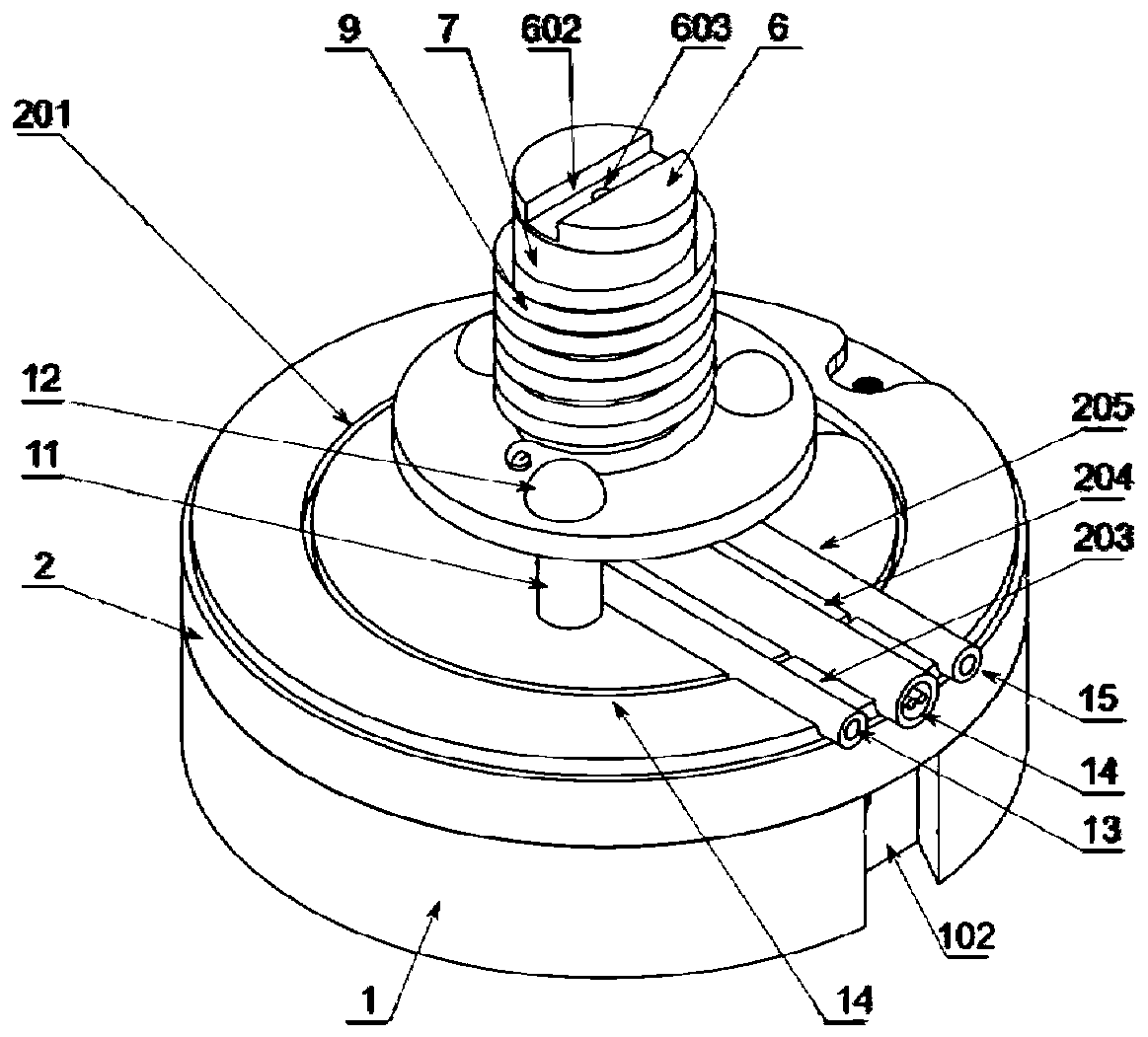

[0062] The invention provides a heating device in vacuum equipment, which includes a heater, an S-type thermocouple 10, a heat-insulating radiation sleeve with a top, a ceramic heat-insulating base 2, a stainless steel base and a thermal electron suppression system.

[0063] The heater includes a heating ceramic core 6, a heating ceramic sleeve 7, a heating wire and a ceramic thermal insulation coating. The upper end of the heating ceramic core 6 has a ceramic cap 601, and the center is provided with a through hole 603 for introducing the S-type thermocouple 10. The ceramic cap 601 is provided with a groove 602 embedded in the sample for heating; the heating ceramic sleeve 7 is a flange pipe structure , the outer diameter of which is the same as that of the ceramic cap 601 of the heating ceramic core 6; the heating ceramic core 6 is coaxially set on the heating ceramic sleeve 7. The heating wire includes a first heating wire 8 and a second heating wire 9, and the material is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com