Quick-frozen salted egg yolk buns and making method thereof

A technology of quick-frozen salted eggs and a production method, which is applied in the field of food processing, can solve the problems of incongruity, fishy taste, etc., and achieve the effects of good emulsification, reasonable nutrition and novel varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

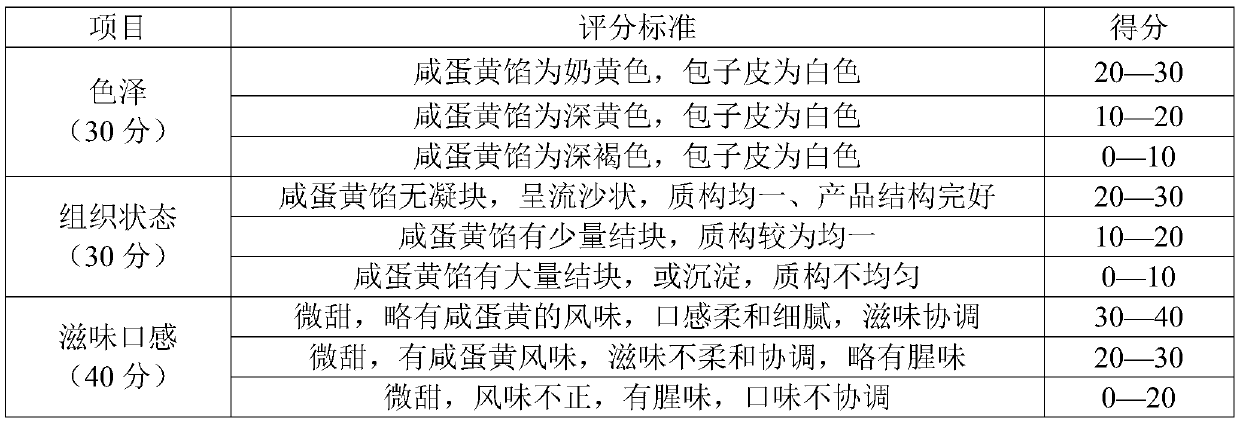

Examples

Embodiment 1

[0032] A processing method of quick-frozen salted egg yolk steamed stuffed bun is characterized in that it mainly comprises the following steps:

[0033] (1) Weigh raw materials according to the following parts by weight: 500 parts of all-purpose flour, 100 parts of water, 60 parts of salted egg yolk, 30 parts of egg cream, 8 parts of table salt, 16 parts of white sugar, and 7 parts of rice wine; Carry out with the weight part in step (1); The mass ratio of salted egg yolk and trypsin is 100:0.1 in step (4), the mass ratio of salted egg yolk and dry yeast is 100:0.1; In step (5), flour and dry The mass ratio of yeast is 100:1.

[0034] (2) Put the salted egg yolk in a refrigerator at -18°C for 12 hours, then pulverize it, and filter it through a 20-mesh filter to obtain salted egg yolk powder;

[0035] (3) Mix the salted egg yolk powder obtained in step (2) with whipped cream evenly, add sugar (accounting for 60% of the total sugar content), salt and rice wine after beating f...

Embodiment 2

[0043] A method for processing steamed stuffed buns with salted egg yolk is characterized in that it mainly comprises the following steps:

[0044] (1) The raw materials are weighed according to the following parts by weight: 500 parts of all-purpose flour, 100 parts of water, 30 parts of salted egg yolk, 30 parts of egg cream, 8 parts of table salt, 20 parts of white sugar, and 7 parts of rice wine. Carry out with the weight part in step (1), the mass ratio of salted egg yolk and trypsin in step (4) is 100:0.1, the mass ratio of salted egg yolk and dry yeast is 100:0.1; The mass ratio of yeast is 100:1;

[0045] (2) Put the salted egg yolk in a refrigerator at -18°C for 12 hours, then pulverize it, and filter it through a 20-mesh filter to obtain salted egg yolk powder;

[0046] (3) Mix the salted egg yolk powder obtained in step (2) with whipped cream evenly, add sugar (accounting for 60% of the total sugar content), salt and rice wine after beating for 5 minutes, and conti...

Embodiment 3

[0054] A method for processing steamed stuffed buns with salted egg yolk is characterized in that it mainly comprises the following steps:

[0055] (1) Weigh raw materials according to the following parts by weight: 500 parts of all-purpose flour, 100 parts of water, 60 parts of salted egg yolk, 30 parts of egg cream, 8 parts of table salt, 16 parts of white sugar, and 7 parts of rice wine; Carry out with the weight part in step (1); The mass ratio of salted egg yolk and trypsin is 100:0.1 in step (4), the mass ratio of salted egg yolk and dry yeast is 100:0.1; In step (5), flour and dry The mass ratio of yeast is 100:1;

[0056] (2) Put the salted egg yolk in a refrigerator at -18°C for 12 hours, then pulverize it, and filter it through a 20-mesh filter to obtain salted egg yolk powder;

[0057] (3) Mix the salted egg yolk powder obtained in step (2) with whipped cream evenly, add sugar (accounting for 60% of the total sugar content), salt and rice wine after beating for 5 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com