Preparation method of collagen fiber immobilized tannin loaded nanometer zero-valent Fe-Ni bimetallic ball adsorption reduction material

A technology of collagen fibers and nano-zero valence, which is applied in the field of reuse of waste biomass resources, can solve problems such as weak van der Waals force, instability of nano-zero valent iron, and affecting NZVI repair application, etc., and achieves the effect of ultra-high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

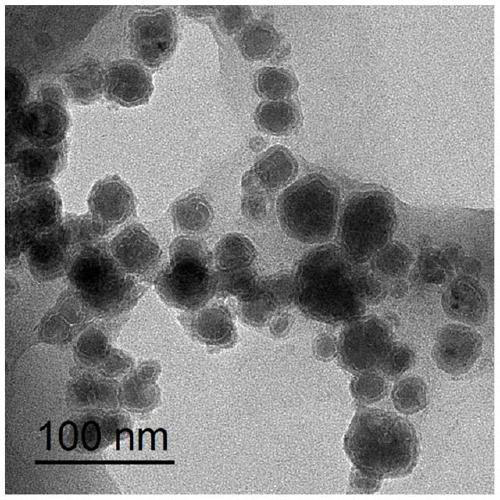

[0031] A preparation method for collagen fiber immobilized tannin loaded nanometer zero-valent Fe-Ni bimetallic sphere adsorption reduction material, comprising the following steps:

[0032] Step 1. After soaking 5g of collagen fibers in 100mL of ultrapure water overnight, add 3g of bayberry tannin, stir for 2 hours, filter, disperse the filtered solid in 100mL of glutaraldehyde solution, adjust the pH to 6.0-6.5, and the temperature is 45 Cross-link for 6 hours at ℃, filter and wash off unreacted glutaraldehyde, and dry at 60℃ for 24 hours to obtain collagen fiber-cured tannin material; the volume concentration of glutaraldehyde solution is 2%;

[0033] Step 2: Disperse 1 g of collagen fiber solidified tannin material in 100 mL of ultrapure water, then add 27 mL of ferric chloride solution with a concentration of 1 g / L, adjust the pH to 2.0, and stir and react at 25 ° C for 4 hours to obtain a mixed solution , add 27mL of nickel chloride solution with a concentration of 1g / L ...

Embodiment 2

[0036] A preparation method for collagen fiber immobilized tannin loaded nanometer zero-valent Fe-Ni bimetallic sphere adsorption reduction material, comprising the following steps:

[0037]Step 1. After soaking 5g of collagen fibers in 100mL of ultrapure water overnight, add 5g of bayberry tannin, stir for 2 hours, filter, disperse the filtered solid in 100mL of glutaraldehyde solution, adjust the pH to 6.0-6.5, and the temperature is 45 Cross-link for 6 hours at ℃, filter and wash off unreacted glutaraldehyde, and dry at 60℃ for 24 hours to obtain collagen fiber-cured tannin material; the volume concentration of glutaraldehyde solution is 3%;

[0038] Step 2: Disperse 1 g of collagen fiber solidified tannin material in 100 mL of ultrapure water, then add 25 mL of ferric nitrate solution with a concentration of 1 g / L, adjust the pH to 2.0, and stir and react at 25°C for 4 hours to obtain a mixed solution. Add 25mL of nickel nitrate solution with a concentration of 1g / L into t...

Embodiment 3

[0041] A preparation method for collagen fiber immobilized tannin loaded nanometer zero-valent Fe-Ni bimetallic sphere adsorption reduction material, comprising the following steps:

[0042] Step 1. After soaking 5g of collagen fibers in 100mL of ultrapure water overnight, add 3g of bayberry tannin, stir for 2 hours, filter, disperse the filtered solid in 100mL of glutaraldehyde solution, adjust the pH to 6.0-6.5, and the temperature is 45 Cross-link for 6 hours at ℃, filter and wash off unreacted glutaraldehyde, and dry at 60℃ for 24 hours to obtain collagen fiber-cured tannin material; the volume concentration of glutaraldehyde solution is 3%;

[0043] Step 2: Take 1g of collagen fiber solidified tannin material and disperse it in 100mL of ultrapure water, then add 25mL of ferrous chloride solution with a concentration of 1g / L, adjust the pH to 2.0, stir and react at 25°C for 4h, and obtain a mixed solution, add 25mL of nickel nitrate solution with a concentration of 1g / L in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com