Gas hydrate generation/decomposition system and method for in-situ Raman analysis

A gas hydrate and in-situ Raman technology, applied in the field of hydrate experiments, can solve problems such as difficult sampling, inability to analyze hydrates, difficulty in sample transfer, etc., and achieve the effect of eliminating experimental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

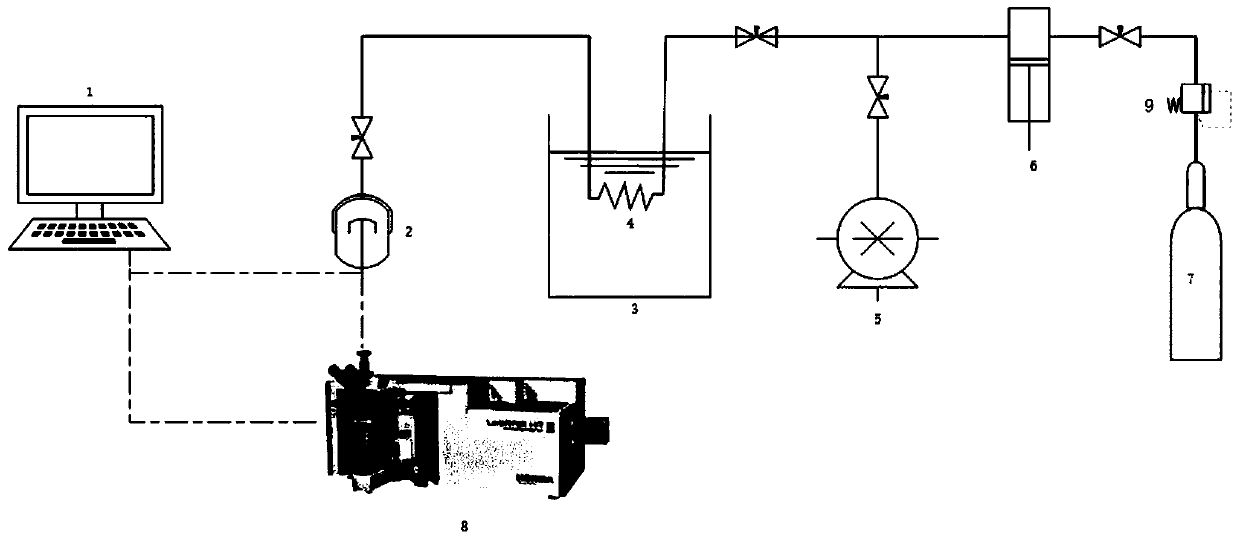

[0025] This embodiment is a gas hydrate generation / decomposition system for in-situ Raman analysis, taking the methane hydrate generation / decomposition experiment as an example, combining figure 1 , the process of generating the experiment is as follows:

[0026] The gas cylinder 7 is filled with high-purity methane gas with a purity of 99.99%, and the plunger pump 6 is filled with scientific-grade deuterated methane gas with a purity of 99.98%;

[0027] Add deionized water into the reactor 3, and use the temperature sensor and liquid nitrogen temperature control parts to lower the temperature of the reactor 3 below 0°C to freeze the deionized water to prevent water from being drawn out of the reactor 3 due to vacuum; Open the vacuum pump 3 and the valve after freezing, and close the vacuum pump 3 and the valve after the reactor 3 is evacuated;

[0028] Close the needle valve at the connection between the pre-cooling device 4 and the reactor 3, unscrew the knob of the methane...

Embodiment 2

[0038] Taking the ethane hydrate formation / decomposition experiment as an example, combined with figure 1 , the process of generating the experiment is as follows:

[0039] The gas cylinder 7 is filled with 95% high-purity methane gas, 5% ethane, propane mixed gas in any ratio, and the plunger pump 6 is filled with all deuterated 95% high-purity methane gas and 5% ethane propane gas;

[0040] The steps are exactly the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com