Electromagnetic sensor for monitoring state of elevator traction steel belt and monitoring method

An electromagnetic sensor, elevator traction technology, applied in the direction of instruments, measuring devices, material magnetic variables, etc., can solve the problem of simultaneous detection and accurate positioning of elevator traction steel belt defects, inability to accurately locate the traction steel belt, and inability to distinguish aging There are no problems such as broken strands, and the magnetization effect is ideal, the signal anti-interference ability is strong, and the weight is light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

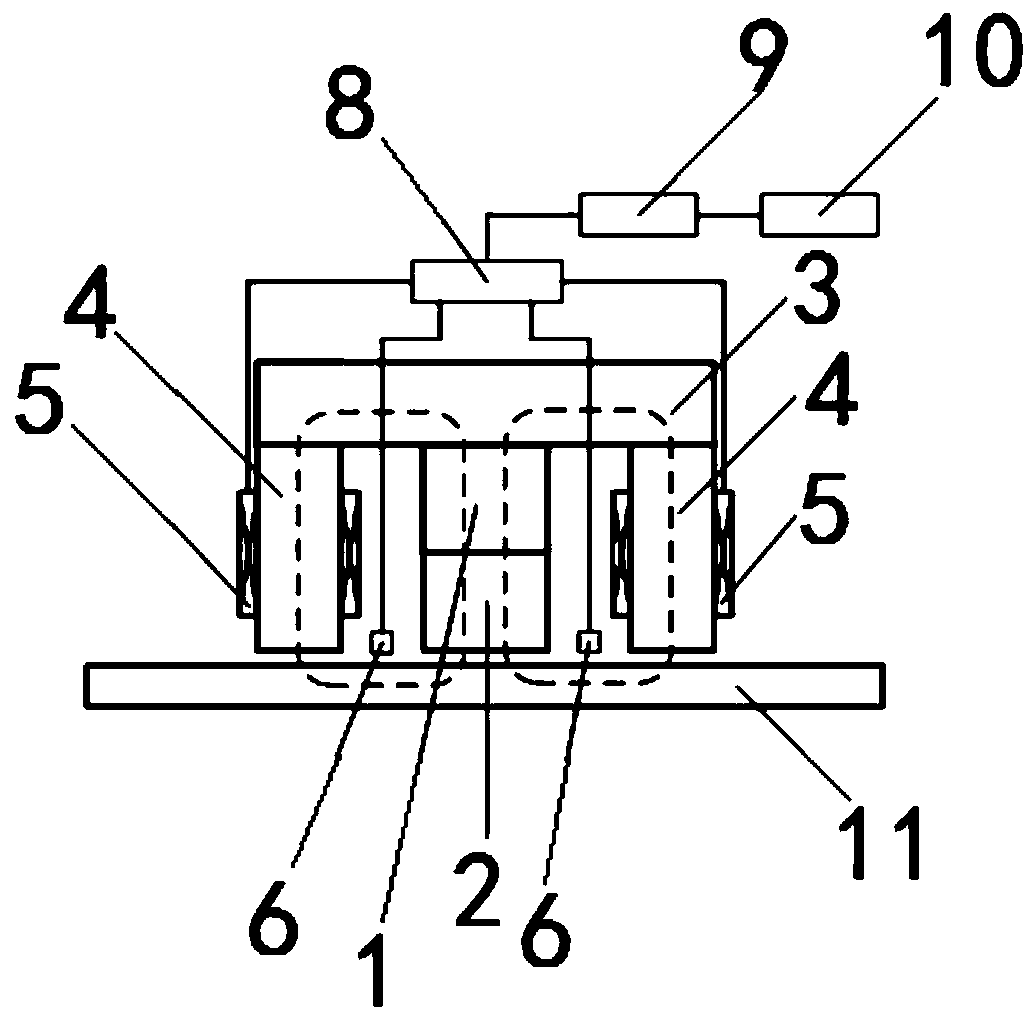

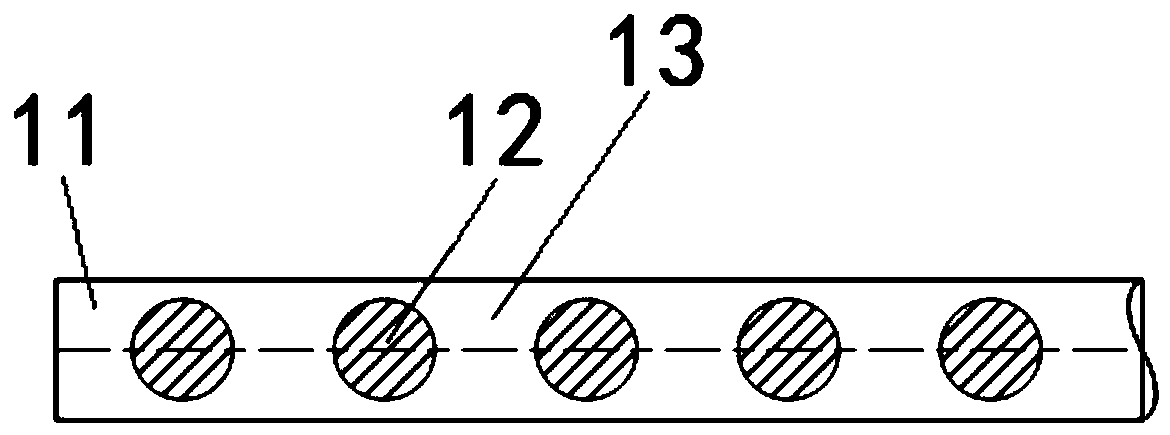

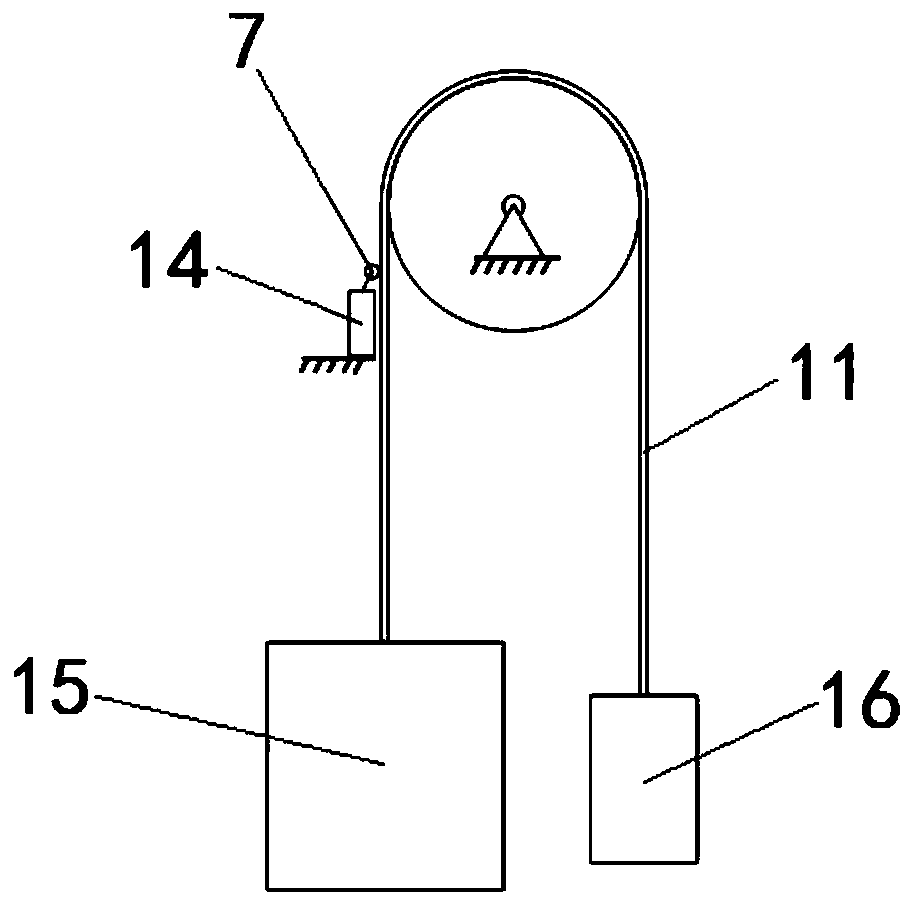

[0037] As an implementation, such as figure 1 As shown, an electromagnetic sensor and a monitoring method for monitoring the state of the elevator traction steel belt include a magnetic circuit module and a detection module; the magnetic circuit module consists of an excitation magnetic source 1, an intermediate yoke arm 2, a yoke beam 3 and a yoke side The yoke side arm 4 is distributed on both sides of the middle yoke arm 2, the yoke beam 3 is fixedly connected to the middle yoke arm 2 and the yoke side arm 4, and the excitation magnetic source 1 is set on the middle yoke arm 2 The detection module is made up of magnetic flux detection coil 5, magnetic sensor 6, displacement sensor 7 and signal processor 8, magnetic flux detection coil 5 obtains magnetic flux signal, magnetic sensor 6 detects magnetic flux leakage signal, displacement sensor 7 collects position signal, signal processing The device 8 receives the signal and analyzes and processes it, so as to realize the moni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com