Numerical-control machine tool feeding control compensation method based on Actor-Critic algorithm

A CNC machine tool and feed control technology, applied in computer control, program control, general control system, etc., can solve problems such as servo system compensation and parameter tuning that have not yet been applied, to improve dynamic performance, improve efficiency, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

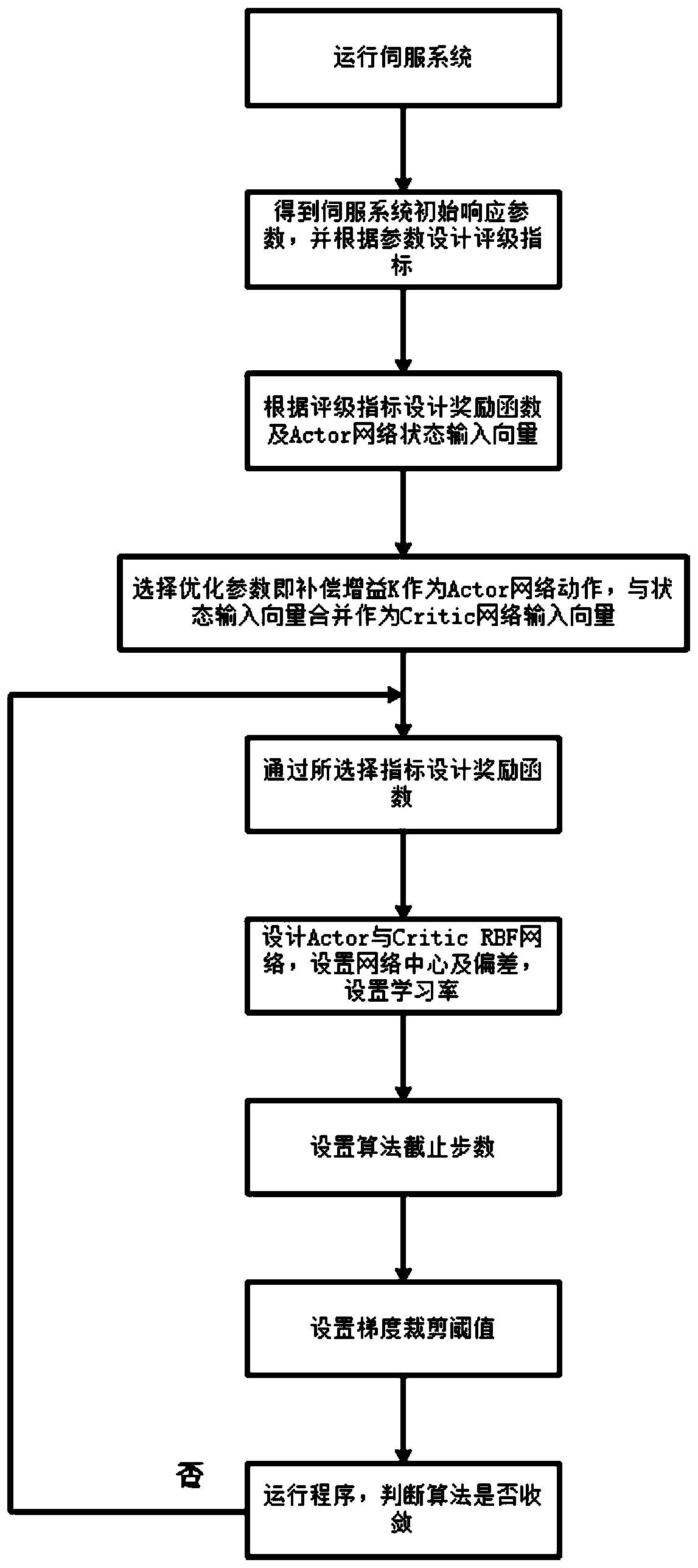

[0043] Examples, see figure 1 , a feed control compensation method for CNC machine tools based on the Actor-Critic algorithm, comprising the following steps:

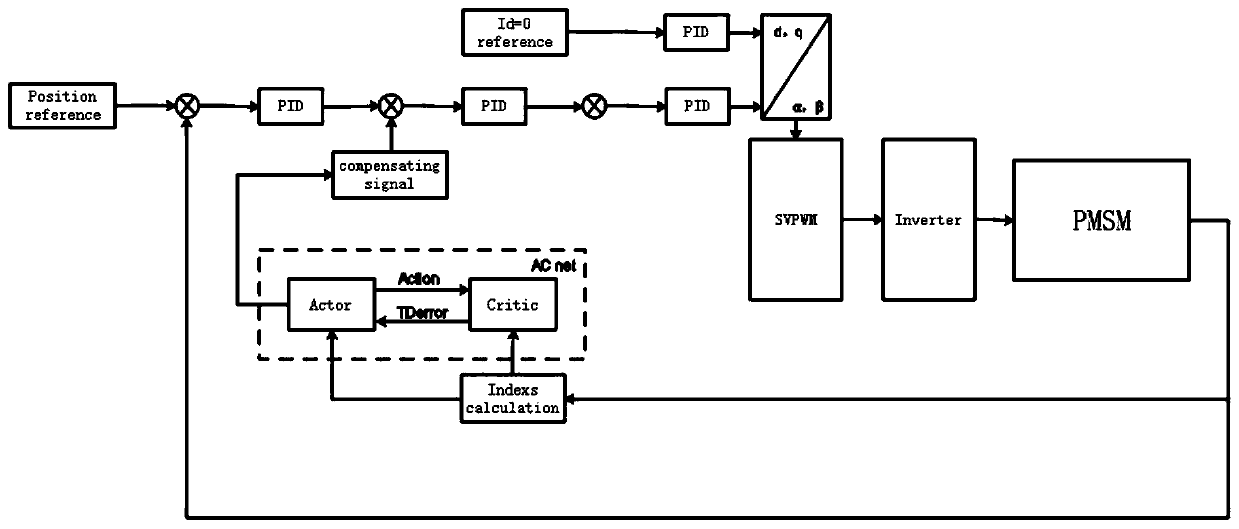

[0044] Step 1) Model the CNC machine feed servo system through the Simulink simulation model, such as figure 2As shown, the model includes a PID controller, an inverter, a permanent magnet synchronous motor, and a detection link. The controlled object is the position of the feed shaft, and the detection link includes an incremental encoder, a current sensor, and a motor output torque sensor. The detected physical quantities include position, speed, current, and torque;

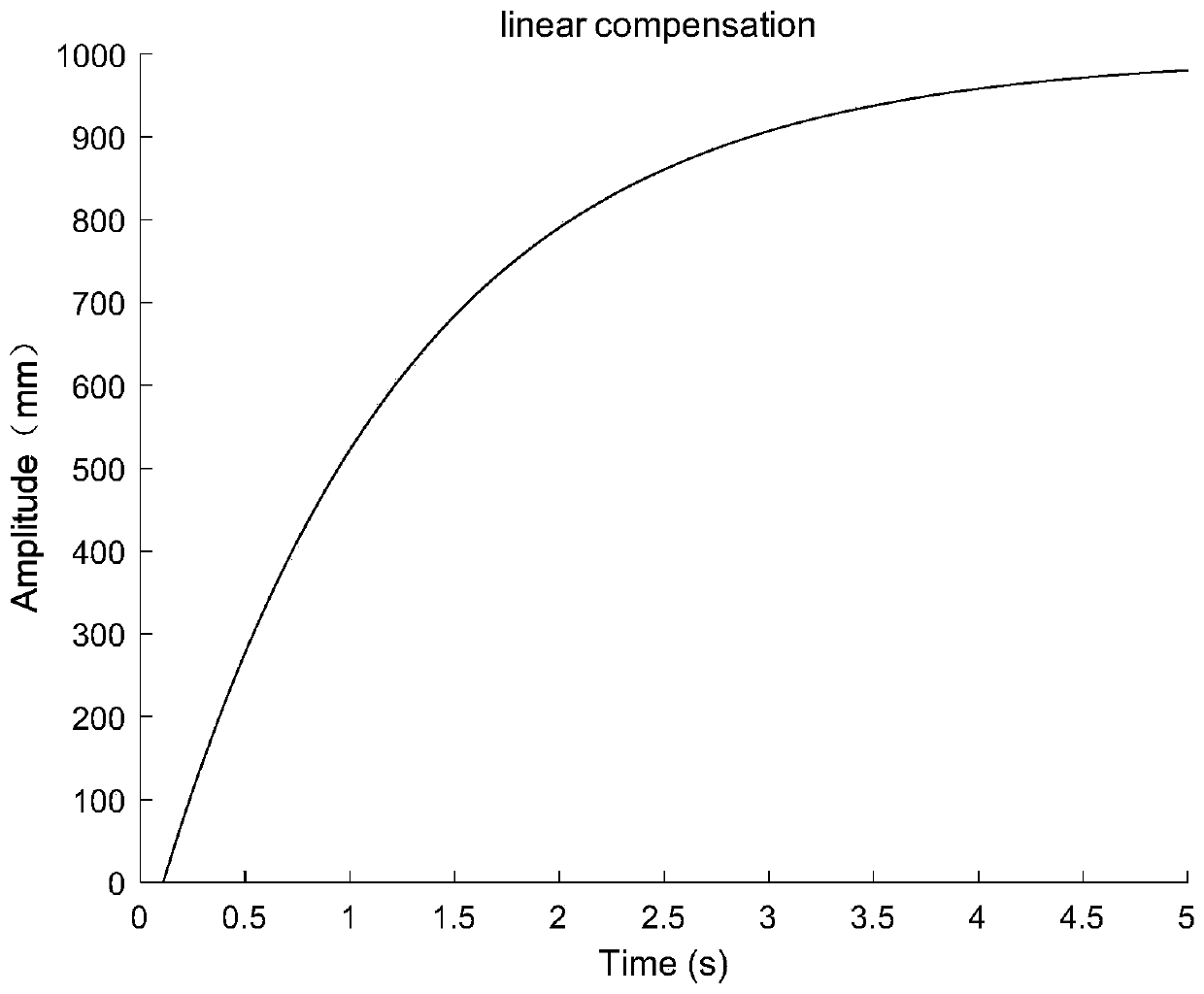

[0045] refer to image 3 , this embodiment adopts the CNC machine tool feed servo system with permanent magnet synchronous motor as the actuator, which is composed of PID controller, inverter, permanent magnet synchronous motor and monitoring system. Among them, the number of poles of permanent magnet synchronous motor is 8, the preset position refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com