Rare earth alloy doped zinc-manganese battery and preparation method thereof

A zinc-manganese battery, rare earth alloy technology, applied in dry batteries, battery electrodes, circuits, etc., can solve the problems of short service life and insufficient discharge performance, reduce the corrosion rate of hydrogen evolution, strong resistance to acid and alkali corrosion of electrolyte, The effect of increasing the operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

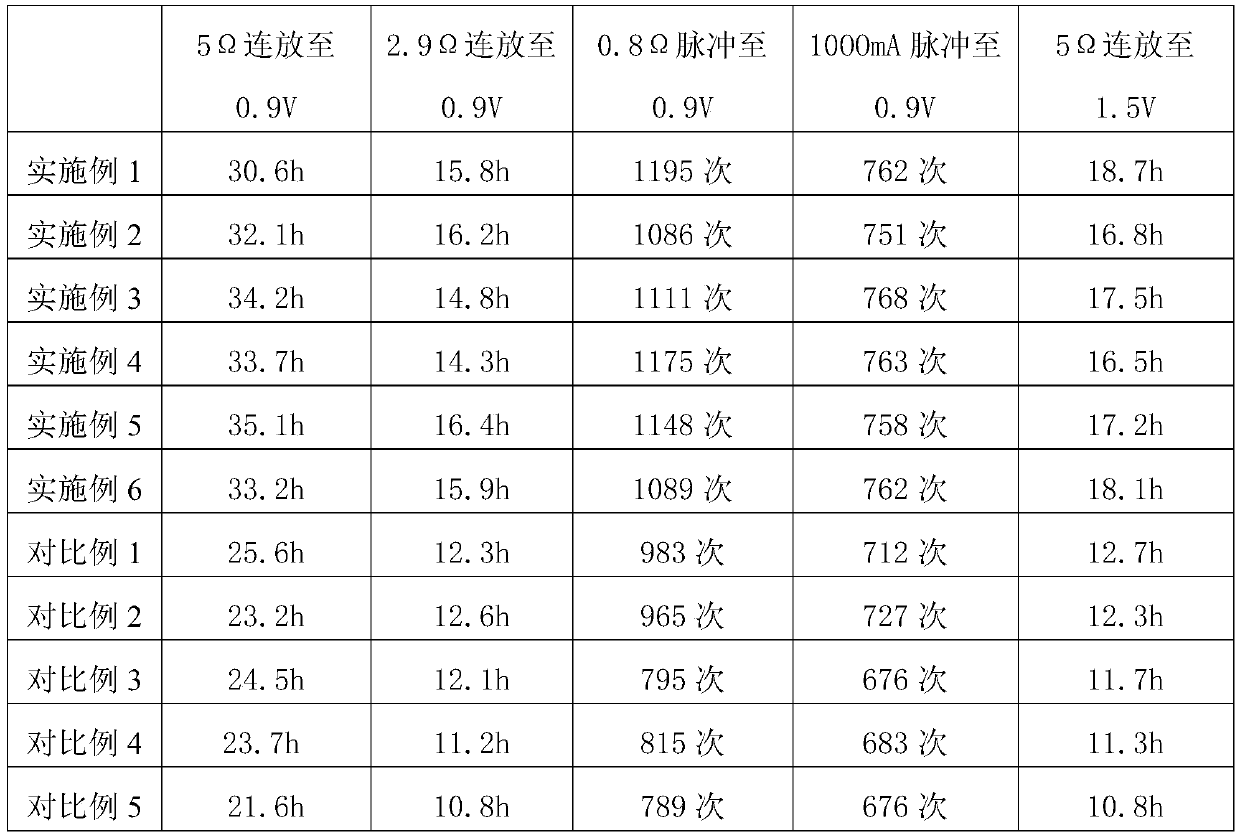

Examples

Embodiment 1

[0033] A zinc-manganese battery doped with a rare earth alloy, the zinc-manganese battery includes a positive electrode ring, a negative electrode zinc paste, a diaphragm and an electrolyte, the positive electrode ring is composed of electrolytic manganese dioxide, a conductive agent and an electrolyte solution, and the negative electrode zinc The paste is composed of the following raw materials in mass fractions: 57.99wt% zinc powder, 1.5wt% binder, 40wt% electrolyte, 0.5wt% composite additive and 100ppm rare earth metal.

[0034] The zinc powder is nano zinc powder with a particle diameter of 500nm.

[0035] The binder is composed of carboxymethyl cellulose and polyacrylic acid, and the mass ratio of carboxymethyl cellulose and polyacrylic acid is 2:1.

[0036] The electrolyte is composed of the following raw materials in parts by weight: 10 parts of potassium hydroxide, 30 parts of disodium tetrahydroxy zincate and 40 parts of deionized water.

[0037] The rare earth metal...

Embodiment 2

[0052] A zinc-manganese battery doped with a rare earth alloy, the zinc-manganese battery includes a positive electrode ring, a negative electrode zinc paste, a diaphragm and an electrolyte, the positive electrode ring is composed of electrolytic manganese dioxide, a conductive agent and an electrolyte solution, and the negative electrode zinc The paste is composed of the following raw materials by mass fraction: 64.95wt% zinc powder, 3.6wt% binder, 29.6wt% electrolyte, 1.8wt% composite additive and 500ppm rare earth metal. The zinc powder is nanometer zinc powder with a particle diameter of 600nm.

[0053] The binder is composed of carboxymethyl cellulose, sodium silicate and polymethacrylate. The mass ratio of carboxymethyl cellulose, sodium silicate and polymethacrylate is 2:1:1.

[0054] The electrolyte is composed of the following raw materials in parts by weight: 30 parts of potassium hydroxide, 20 parts of disodium tetrahydroxy zincate and 60 parts of deionized water. ...

Embodiment 3

[0070] A zinc-manganese battery doped with a rare earth alloy, the zinc-manganese battery includes a positive electrode ring, a negative electrode zinc paste, a diaphragm and an electrolyte, the positive electrode ring is composed of electrolytic manganese dioxide, a conductive agent and an electrolyte solution, and the negative electrode zinc The paste is composed of the following raw materials in mass fraction: 65.9wt% zinc powder, 6wt% binder, 25wt% electrolyte, 3wt% composite additive and 1000ppm rare earth metal.

[0071] The zinc powder is nano zinc powder with a particle diameter of 900nm.

[0072] The binder is composed of carboxymethyl cellulose, sodium silicate, polyacrylic acid and polymethacrylate. The mass ratio of carboxymethyl cellulose, sodium silicate, polyacrylic acid and polymethacrylate is 3:0.5:1:1.5.

[0073] The electrolyte is composed of the following raw materials in parts by weight: 50 parts of potassium hydroxide, 30 parts of disodium tetrahydroxy z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com