Colorant compound and coloring composition comprising same

A technology of coloring composition and compound, which is applied in the photoplate-making process of patterned surface, optics, and optomechanical equipment, etc. It can solve the problems such as the difficulty in manufacturing thin-film color filters, and the difficulty in increasing the pigment content of photosensitive resin compositions, and achieves stable Color reproducibility, excellent heat resistance and solubility, effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

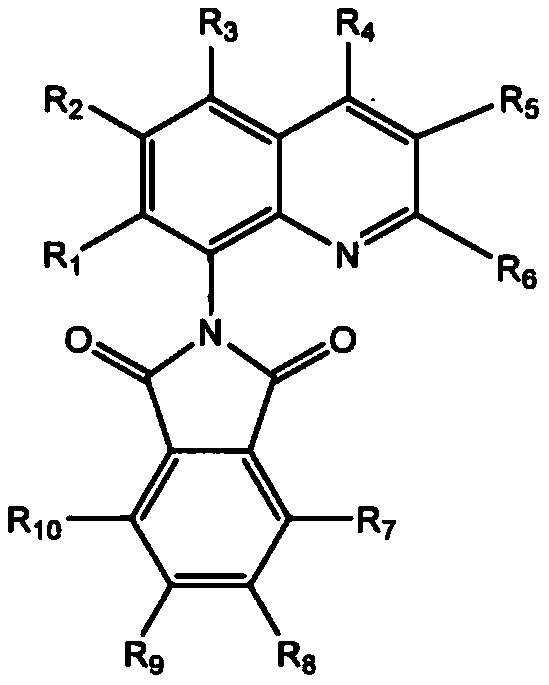

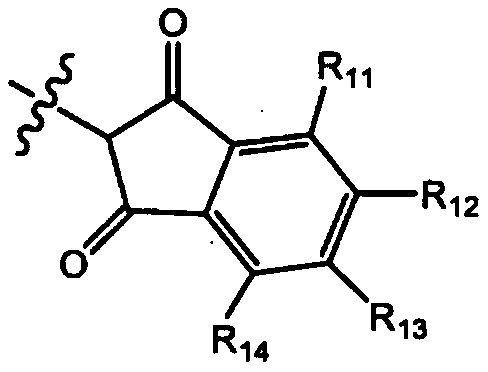

[0191] Preparation Example 1: Synthesis of Compound 1

[0192]

[0193] Compound A was obtained according to the method described in US Patent Publication No. 6849116B2. In detail, 25.5 g of phthalimide and 7.4 g of paraformaldehyde were mixed and added to 560 g of 3.6% by weight of oleum at 25°C. The mixture was heated to 50°C and stirred for 30 minutes.

[0194] 100 g of Pigment Yellow 138 (BASF) was added thereto, and the mixture was heated to 100° C. and stirred for 3 hours. Subsequently, the mixture was added to 3500 g of water, and stirred at 60° C. for 30 minutes. The precipitated product thus obtained was filtered and washed with water until the product became neutral, and then dried in a vacuum oven at 90° C. to obtain compound (A).

[0195] Next, 3g (3.417mmol) compound (A), 0.52g (7.033mmol) 1-butanethiol and 1.94g (14.06mmol) K 2 CO 3 Place in 500ml single neck RBF and stir at 60°C for 24 hours. The reaction solution was cooled to room temperature, and f...

preparation example 2

[0196] Preparation Example 2: Synthesis of Compound 2

[0197]

[0198] Compound B was obtained according to the method described in US Patent Publication No. 6849116B2 in the same manner as in Preparation Example 1, except that 1,8-naphthalimide was used instead of phthalimide.

[0199] Next, 3g (3.32mmol) compound (B), 0.49g (6.65mmol) 1-butanethiol and 1.83g (13.28mmol) K 2 CO 3 Place in 500ml single neck RBF and stir at 60°C for 24 hours. The reaction solution was cooled to room temperature, and filtered under reduced pressure. The solvent was removed under reduced pressure, and the resultant was purified by column to obtain compound 2. APCI negative MS analysis results showed that the molecular weight of compound 2 was 957.

preparation example 3

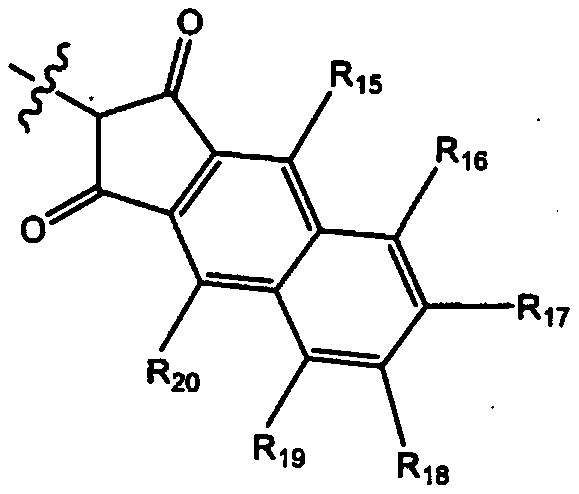

[0200] Preparation Example 3: Synthesis of Compound 3

[0201]

[0202] Compound C was obtained according to the synthesis method described in Korean Patent Publication No. 2013-0137028, and then Compound D was obtained according to the method described in US Patent Publication No. 6849116B2.

[0203] Next, 3g (3.92mmol) compound (D), 0.58g (7.84mmol) 1-butanethiol and 2.17g (15.69mmol) K 2 CO 3 Place in 500ml single neck RBF and stir at 60°C for 24 hours. The reaction solution was cooled to room temperature, and filtered under reduced pressure. The solvent was removed under reduced pressure, and the resultant was purified by column to obtain compound 3. APCI negative MS analysis results showed that the molecular weight of compound 3 was 819.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com