Ultrasonic screening transducer resonance frequency self-locking and real-time correction method and ultrasonic screening transducer power supply circuit

A resonant frequency and transducer technology, which is applied in the field of automatic locking and real-time correction of the resonant frequency of ultrasonic screening transducers, can solve the problem of unstable output frequency of ultrasonic power supply, poor transducer interchangeability, and ultrafine powder screening efficiency Low-level problems, to achieve the effect of avoiding the failure of the circuit board to work normally, high output frequency accuracy, and fast continuous correction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method for self-locking and real-time correction of the resonant frequency of the ultrasonic screening transducer of the present invention includes the following steps:

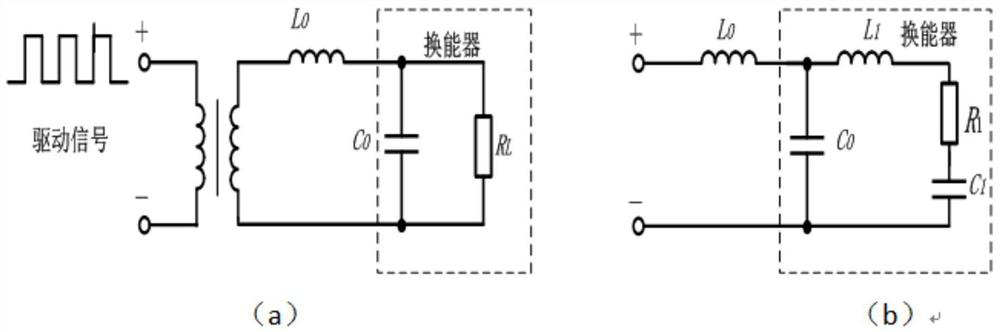

[0031]1) According to the characteristics of the load resonance circuit of the ultrasonic screening transducer, the digital frequency scanning frequency locking method under the condition of constant current source power supply is adopted, the direct digital frequency synthesizer and the DC high voltage terminal isolation detection technology are used, and the frequency scanning and extreme value judgment are used. The method realizes the locking of the resonance frequency of the ultrasonic screening transducer;

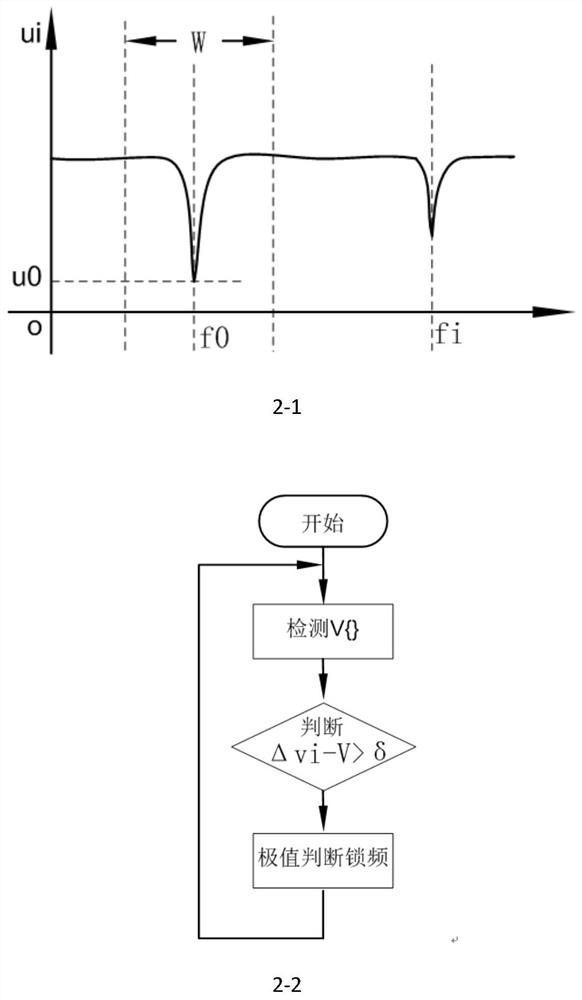

[0032] 2) During the operation of the ultrasonic power supply, the automatic triggering method of the voltage deviation value of the constant current source terminal is used to correct the ultrasonic output frequency in real time; according to the voltage change of the power supply termina...

Embodiment 2

[0034] The ultrasonic screening transducer resonance frequency self-locking and real-time correction method of the present embodiment is different from Embodiment 1:

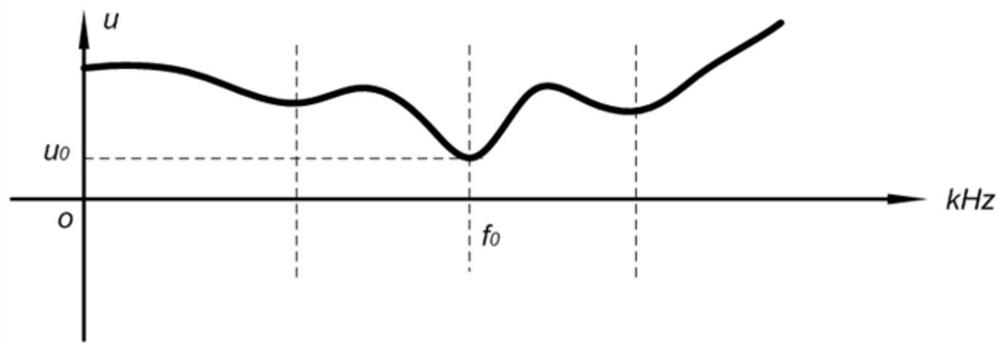

[0035] Further, in the case of constant current source power supply, use different frequencies to drive the ultrasonic screening transducer system to obtain the relationship between the voltage and frequency of the ultrasonic screening transducer circuit; first, use the extreme value judgment method to find out the ultrasonic screening transducer. The resonance point of the ultrasonic screening transducer system, and then let the ultrasonic power supply output the resonance point frequency to achieve frequency locking, and then use the method of automatic threshold triggering to automatically adjust the resonance frequency of the ultrasonic screening transducer in real time during the operation of the ultrasonic screening transducer system. Correction.

Embodiment 3

[0037] The ultrasonic screening transducer resonance frequency self-locking and real-time correction method of the present embodiment is different from Embodiment 1 or Embodiment 2:

[0038] The power supply voltage at both ends of the ultrasonic drive is detected through the isolation of the DC high-voltage terminal, and sent to the single-chip microcomputer for processing through the A-D converter to realize digital frequency scanning; the low-voltage single-chip microcomputer system is used to control the PWM generator to control the size of the current source, so that the ultrasonic power supply works at a constant The low-voltage single-chip microcomputer system uses the extreme value judgment method to find the resonance point frequency of the ultrasonic screening transducer according to the voltage change of the power supply under different frequency points, and then generates a frequency-controlled sinusoidal frequency through the direct digital frequency synthesizer. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com