Eccentric gear and welding process thereof

An eccentric gear and welding technology, which is applied in the direction of belt/chain/gear, hoisting device, manufacturing tools, etc., can solve the problems affecting the production and manufacturing of gears, poor density of casting gears, and large processing workload, so as to avoid excessive Fast cooling, dense gear structure and better quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments, and it should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

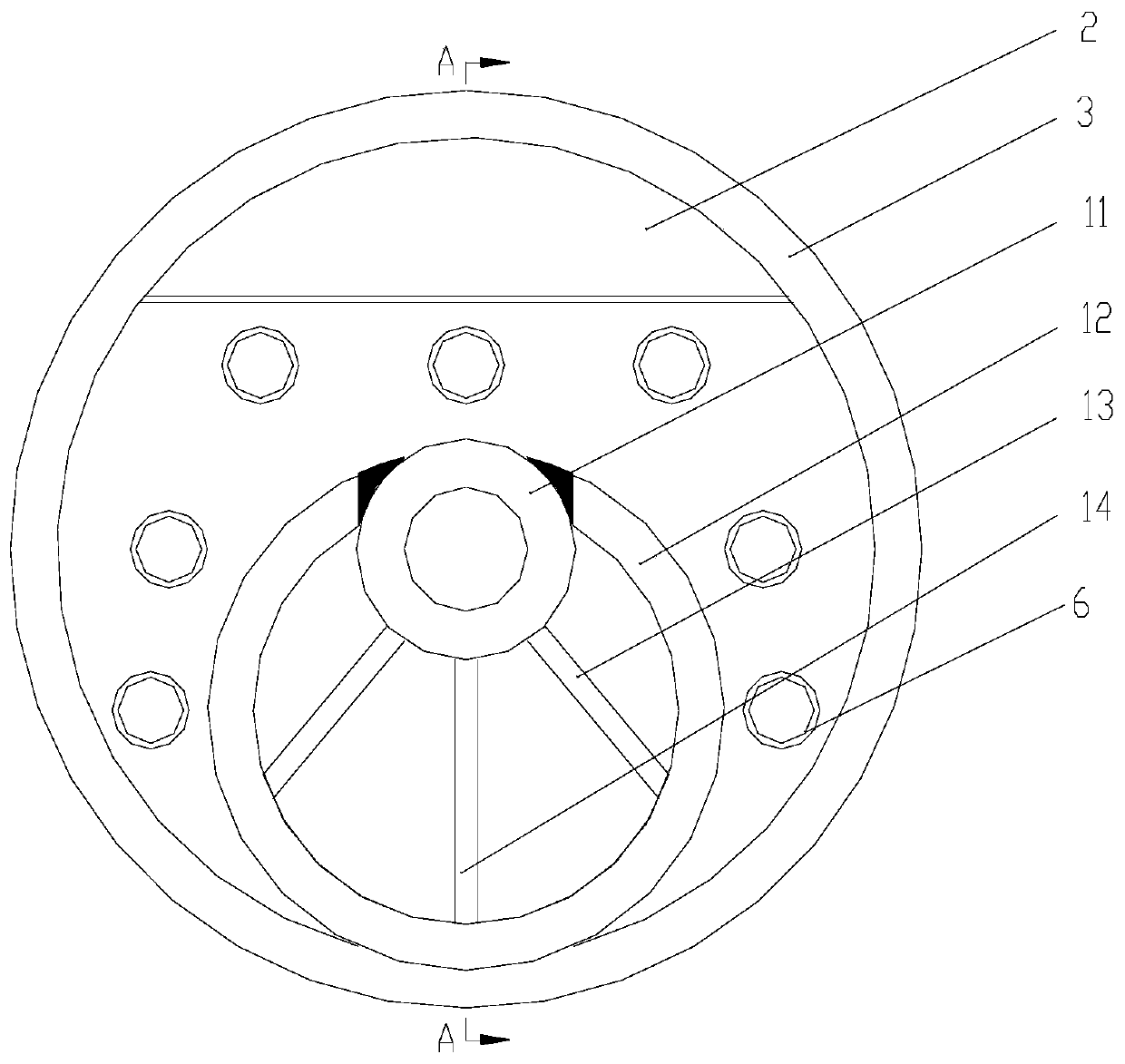

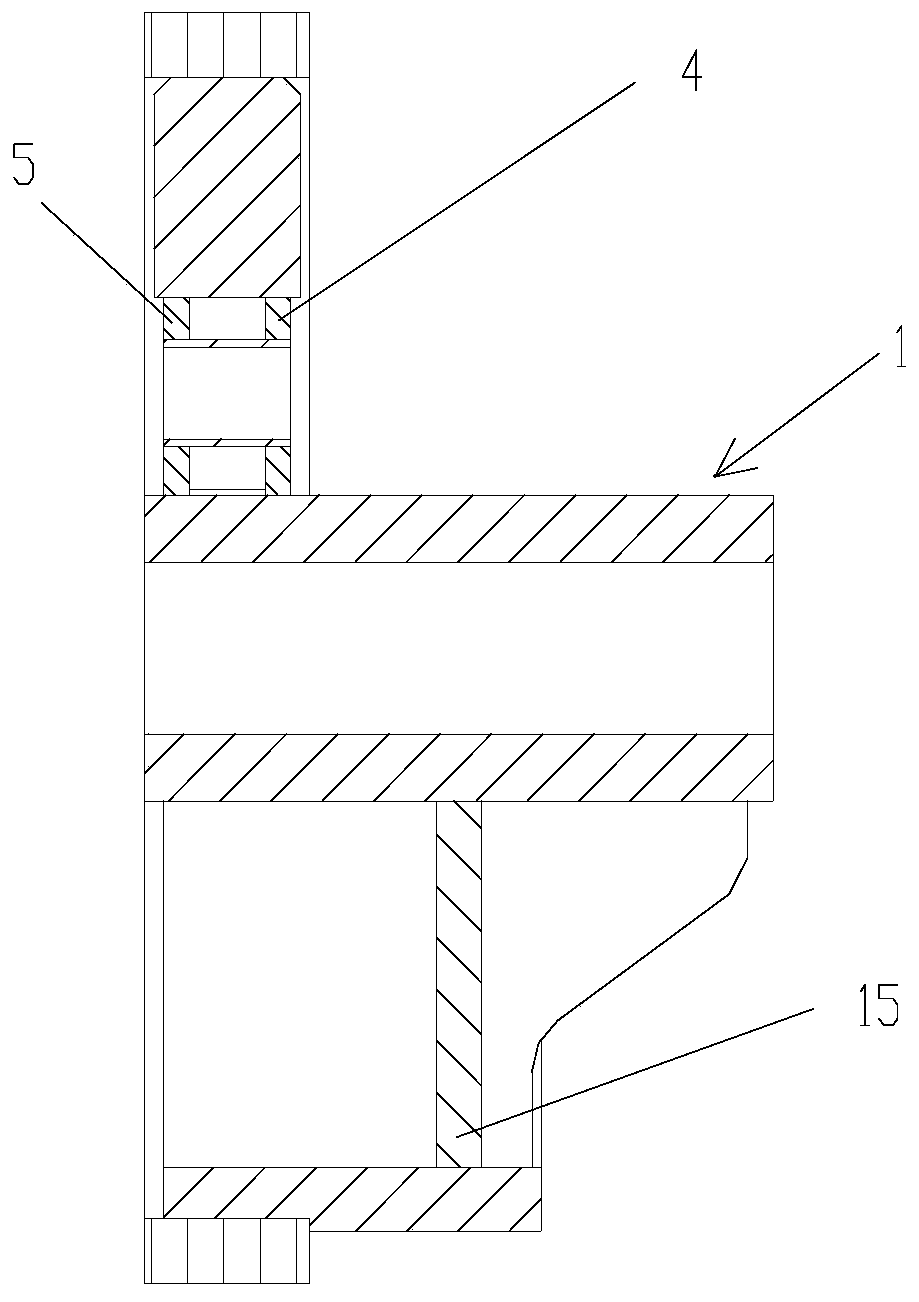

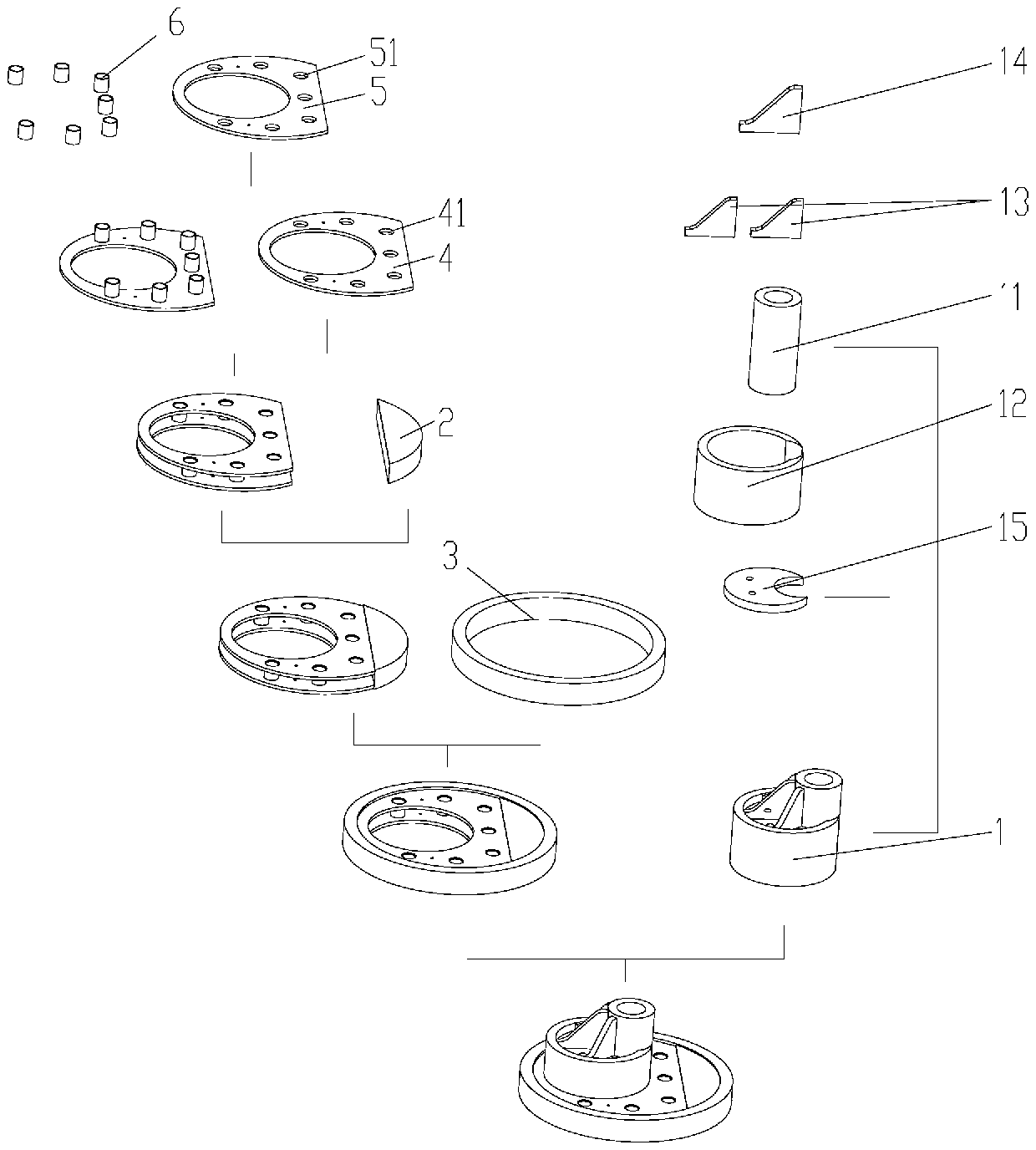

[0032] an eccentric gear such as figure 1 , 2 As mentioned above, it includes the eccentric body assembly 1, the counterweight body 2, the ring gear 3, the first web 4, the second web 5, and the support body 6, and the eccentric body assembly 1 includes the hub 11, the eccentric ring 12, and the outer ribs 13, middle part brace rib 14, eccentric body brace plate 15.

[0033] The first web 4 and the second web 5 are arranged symmetrically at intervals in parallel, the size and structure of the first web 4 and the second web 5 are the same, and the support body 6 is arranged at intervals between the first web 4 and the second web 5 There are multiple and distributed in arcs, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com