Precooler sealing head, precooler and environment control system

A precooler and head technology, applied in the field of aircraft and aircraft maintenance and manufacturing, can solve the problems of large measurement deviation, reduced equipment service life and high cost, and achieve the effects of easy implementation, reduced possibility of failure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Referring now to the accompanying drawings, specific embodiments of the present invention will be described in detail. What is described here is only a preferred embodiment of the present invention, and those skilled in the art can think of other ways to realize the present invention on the basis of the preferred embodiments, and the other ways also fall within the scope of the present invention.

[0042] In a preferred embodiment of the present invention, a precooler head used in an aircraft, a precooler 1 including the precooler head, and an environment control system including the precooler 1 are provided.

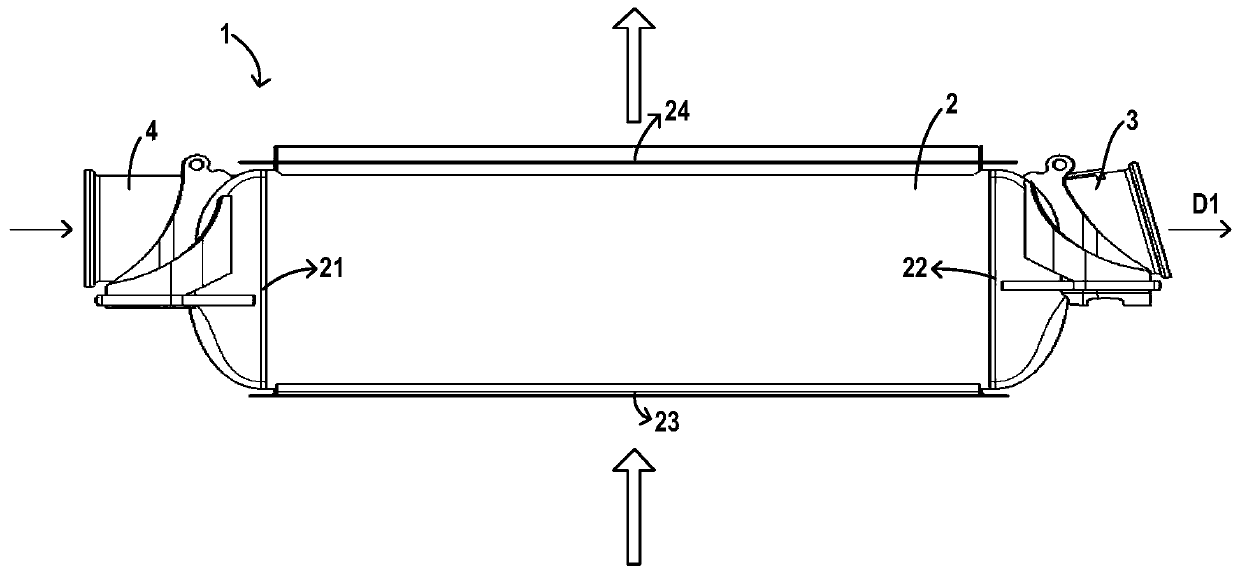

[0043] Specifically, the pre-cooler 1 is used to cool down the high-temperature gas drawn from upstream equipment (such as an engine). Such as figure 1 As shown, the precooler 1 includes a precooler main body 2, and the precooler main body 2 is provided with a hot side inlet 21, a hot side outlet 22, a cold side inlet 23 and a cold side outlet 24, and the hot si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com