Gas collecting device of whole skid booster station

A technology of gas collecting device and supercharging device, which is applied in the direction of combination device, gas fuel, gas/liquid distribution and storage, etc., which can solve the problems of inflexible relocation, large floor area, cumbersome construction, etc., and achieve convenient and flexible installation , small footprint, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

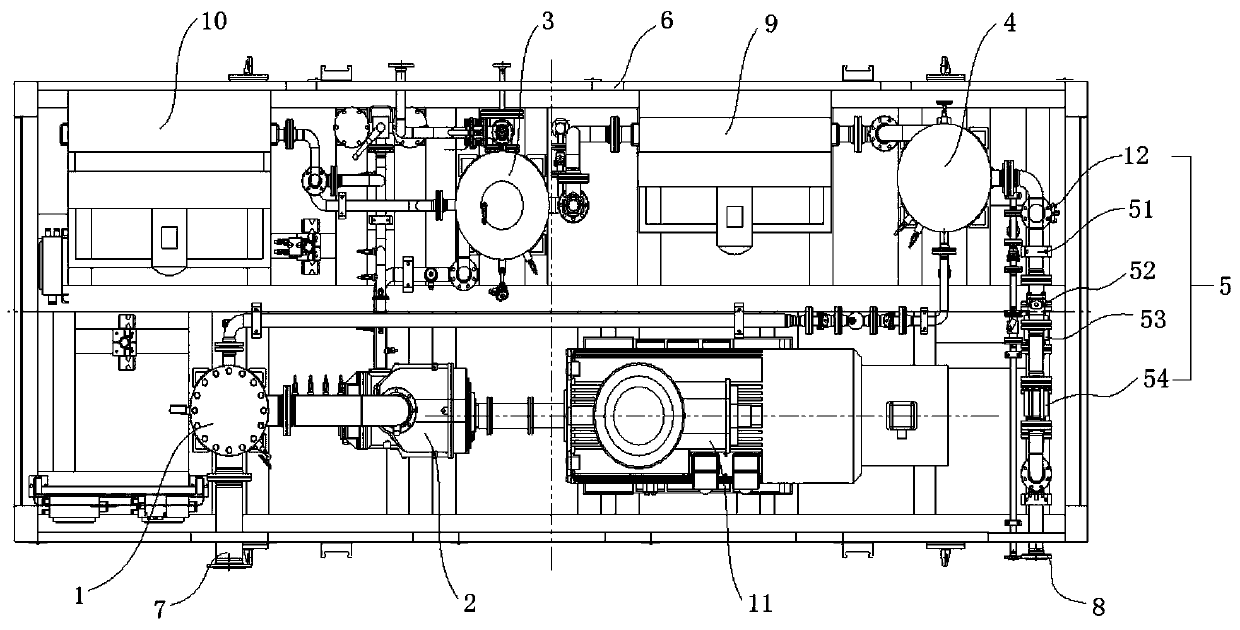

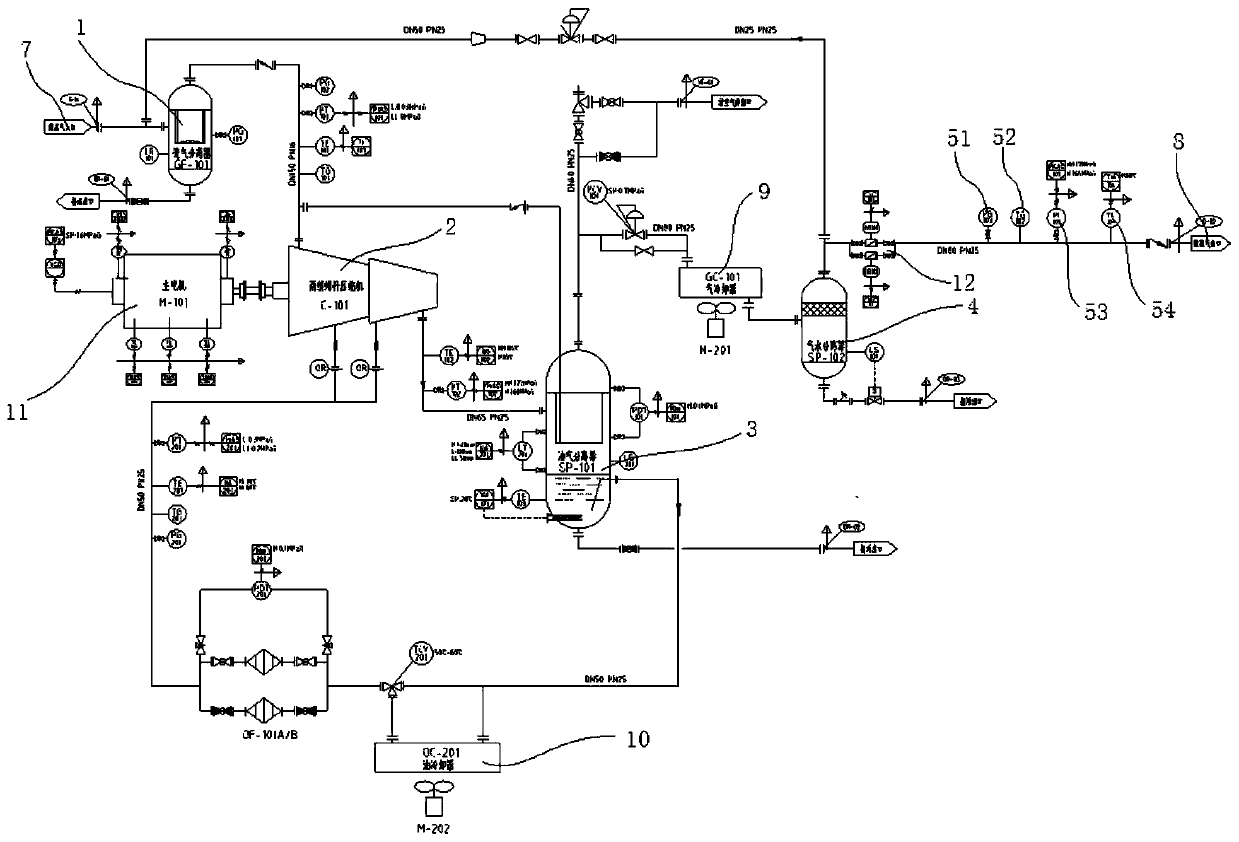

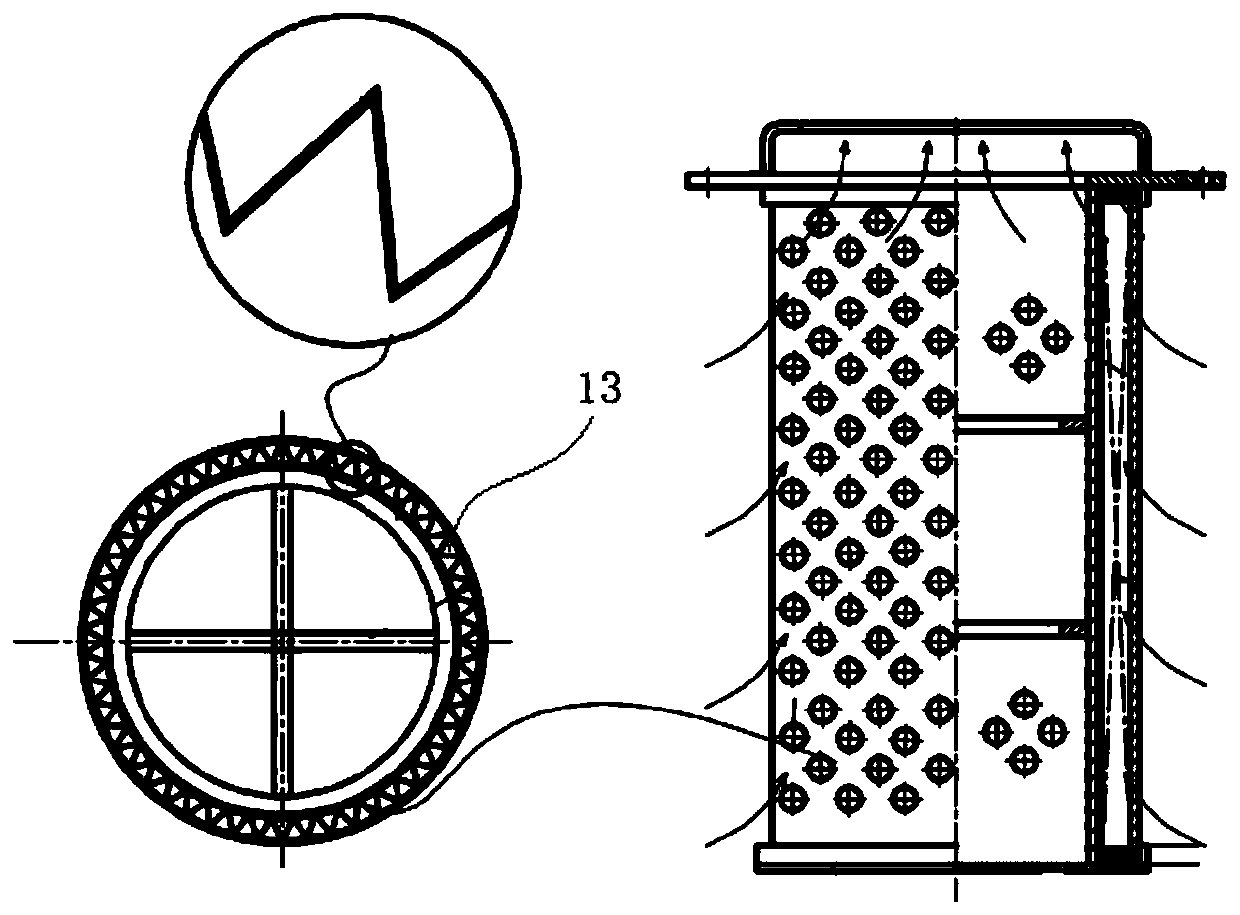

[0020] The following will be combined with figure 1 A detailed introduction to the present invention: the present invention includes an air intake separator 1, a booster device 2, an oil-gas separator 3, a gas-water separator 4, and a metering valve group 5, and they are integrated in a workstation through a pipeline connection. 6, the workstation 6 can be a mobile bracket or a fixed frame; the air inlet end of the air inlet separator 1 is connected with the air inlet 7 of the gas collection device, and the air inlet 7 is used to pass into the coalbed methane, and the coalbed methane The water and impurities are removed through the intake separator 1; the gas outlet end of the intake separator 1 is connected with the oil-gas separator 3 through the booster device 2, and the coalbed gas entering the oil-gas separator 3 is made through the booster device 2 The pressure is increased to facilitate separation; the oil-gas separator 3 is connected with the gas-water separator 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com