Anti-track bituminous pavement cooling structure and material composition of each layer thereof

A technology of asphalt pavement and cooling structure, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of surface layer temperature in the middle surface layer heat deformation, reduce road rutting, and reduce the temperature significantly. Effect of road surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In order to better understand the present invention, the content of the present invention will be further elaborated below in conjunction with the embodiments. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0019] Example 1

[0020] The pavement structure in this embodiment consists of a low thermal conductivity upper layer 1 , a heat storage middle surface layer 2 and a high thermal conductivity lower layer 3 .

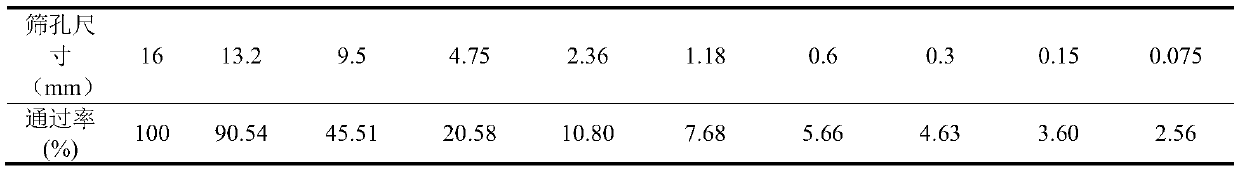

[0021] The upper layer 1 with low thermal conductivity adopts AC-13 mixture, 70# matrix asphalt, 5.0% asphalt ratio, mineral material gradation as shown in Table 1, and 2% ceramic fiber is added.

[0022] Table 1 AC-13 Grading

[0023]

[0024] The heat storage surface layer 2 ...

Embodiment 2

[0033] The pavement structure in this embodiment consists of a low thermal conductivity upper layer 1 , a heat storage middle surface layer 2 and a high thermal conductivity lower layer 3 .

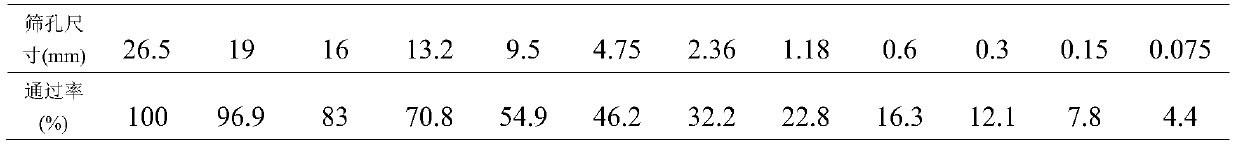

[0034] The upper layer with low thermal conductivity adopts Superpave-13 mixture, 70# base asphalt, 5.2% asphalt ratio, mineral material grading as shown in Table 4, and 3% glass fiber is added.

[0035] Table 4 Superpave-13 gradation

[0036]

[0037] The surface layer of heat storage adopts Superpave-20 mixture, 70# matrix asphalt, 4.4% asphalt ratio, and the mineral material gradation is shown in Table 5, and the same volume of composite phase change material is used to replace mineral powder. The composite phase change material is prepared by using diatomite as a support body to physically adsorb paraffin wax. The preparation method is to completely soak expanded graphite in paraffin wax with 20 carbon atoms, perform stirring and adsorption for 6 hours, and then filter to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com