Preparation method and application method of self-temperature-adjusting road coating material

A coating material and pavement technology, applied in coatings, asphalt coatings, epoxy resin coatings, etc., can solve problems such as temperature shrinkage cracks on the pavement, large temperature differences, and reduced pavement durability, so as to actively adjust the pavement temperature and construction way simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

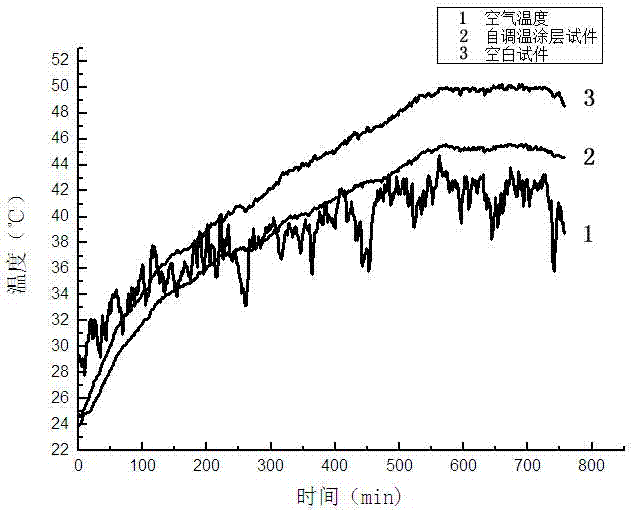

Image

Examples

Embodiment 1

[0036] Step 1: Take 80 parts by weight of vanadium pentoxide powder, 80 parts by weight of oxalic acid and 1 part by weight of tungstate, put them into 150 parts by weight of deionized water, and stir them fully at a temperature of 150°C until the three are completely reaction, and then dry the solution.

[0037] Among them, the tungstate is sodium tungstate.

[0038] Step 2: Thermally decompose the material obtained in Step 1 under a vacuum condition of 380° C. to obtain vanadium dioxide and its dopant nanopowder.

[0039] Step 3: Weigh 20 parts by weight of the nano-powder material obtained by step 2 and add it to 10 parts by weight of emulsified asphalt, then add 10 parts by weight of water-based epoxy resin, 10 parts by weight of curing agent and 10 parts by weight of part of water to obtain a self-regulating pavement coating material.

[0040] The emulsified asphalt is cationic emulsified asphalt, which is made by asphalt, cationic emulsifier and water through the norma...

Embodiment 2

[0044] Step 1: Take 85 parts by weight of vanadium pentoxide powder, 85 parts by weight of oxalic acid and 2 parts by weight of tungstate, put them into 200 parts by weight of deionized water, and stir them fully at a temperature of 165°C until the three are completely reaction, and then dry the solution.

[0045] Among them, the tungstate is calcium tungstate.

[0046] Step 2: Thermally decompose the material obtained in Step 1 under a vacuum condition of 380° C. to obtain vanadium dioxide and its dopant nanopowder.

[0047] Step 3: Weigh 30 parts by weight of the nano-powder material obtained by step 2 and add it to 15 parts by weight of emulsified asphalt, then add 20 parts by weight of water-based epoxy resin, 20 parts by weight of curing agent and 20 parts by weight of part of water to obtain a self-regulating pavement coating material.

[0048] The emulsified asphalt is cationic emulsified asphalt, which is made by asphalt, cationic emulsifier and water through the nor...

Embodiment 3

[0052] Step 1: Take 90 parts by weight of vanadium pentoxide powder, 90 parts by weight of oxalic acid and 4 parts by weight of ammonium fluoride, put them into 250 parts by weight of deionized water, and stir them fully at a temperature of 180°C until the three parts are completely reaction, and then dry the solution.

[0053] Among them, tungstate is ammonium tungstate.

[0054] Step 2: Thermally decompose the material obtained in Step 1 under a vacuum condition of 380° C. to obtain vanadium dioxide and its dopant nanopowder.

[0055] Step 3: Weigh 30 parts by weight of the nano-powder material obtained by step 2 and add it to 15 parts by weight of emulsified asphalt, then add 20 parts by weight of water-based epoxy resin, 20 parts by weight of curing agent and 30 parts by weight of part of water to obtain a self-regulating pavement coating material.

[0056]The emulsified asphalt is cationic emulsified asphalt, which is made by asphalt, cationic emulsifier and water throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com