A method for beautifying jointing of floor tiles

A technology for ceramic tiles and beautifying joints, which is applied in the direction of construction and building construction, can solve the problems of reduced fluidity of beautifying joints, long setting time of beautifying joints, troublesome construction of beautifying joints, etc., and achieves a stable and reliable extrusion effect, shortening the The construction period and the effect of improving the efficiency of beautiful seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

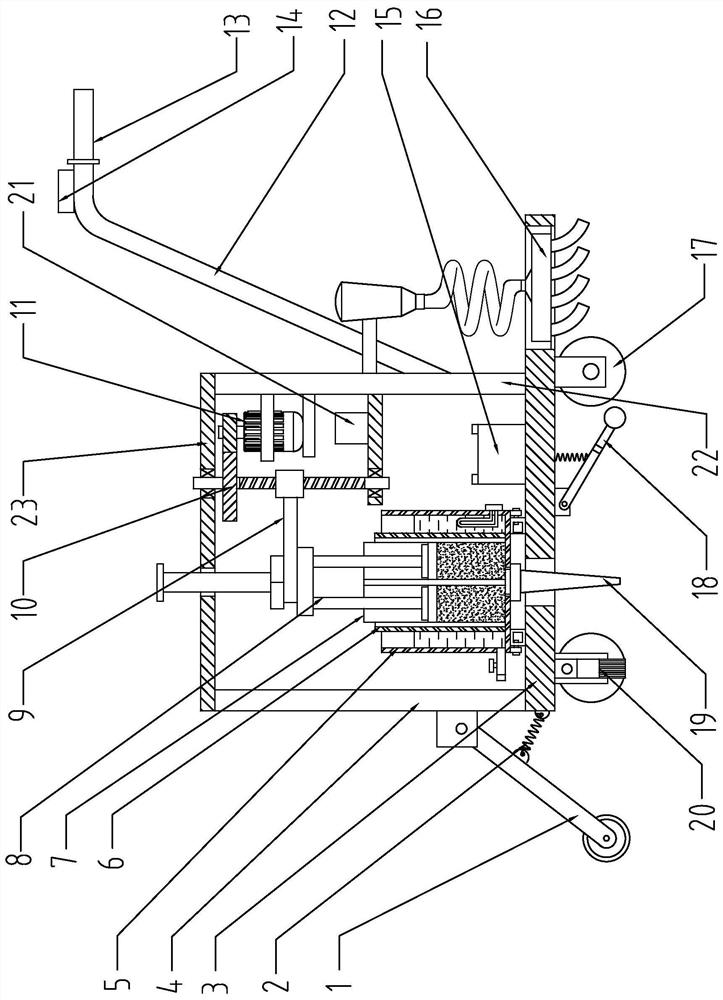

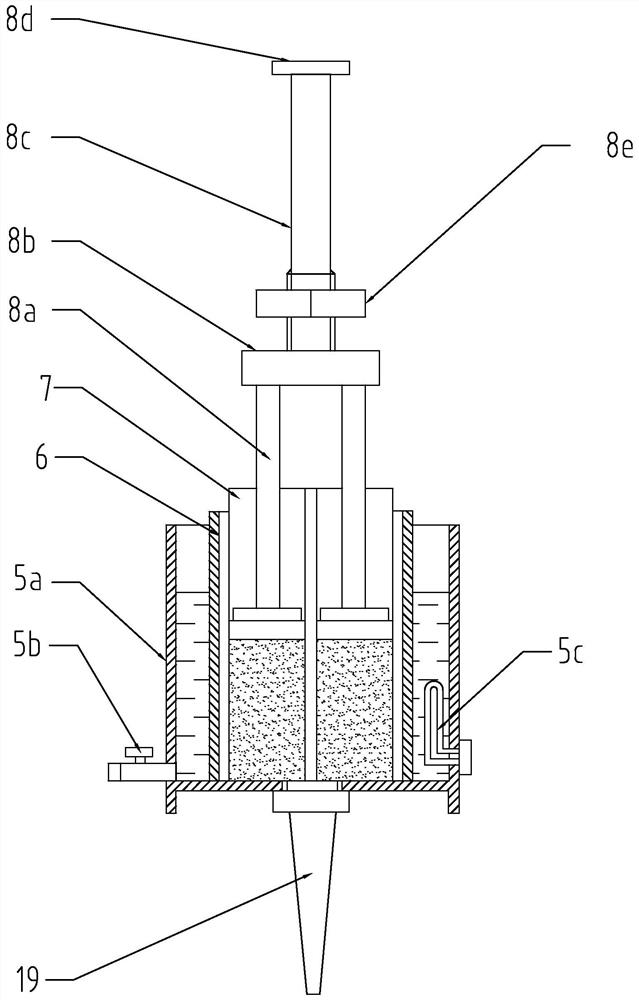

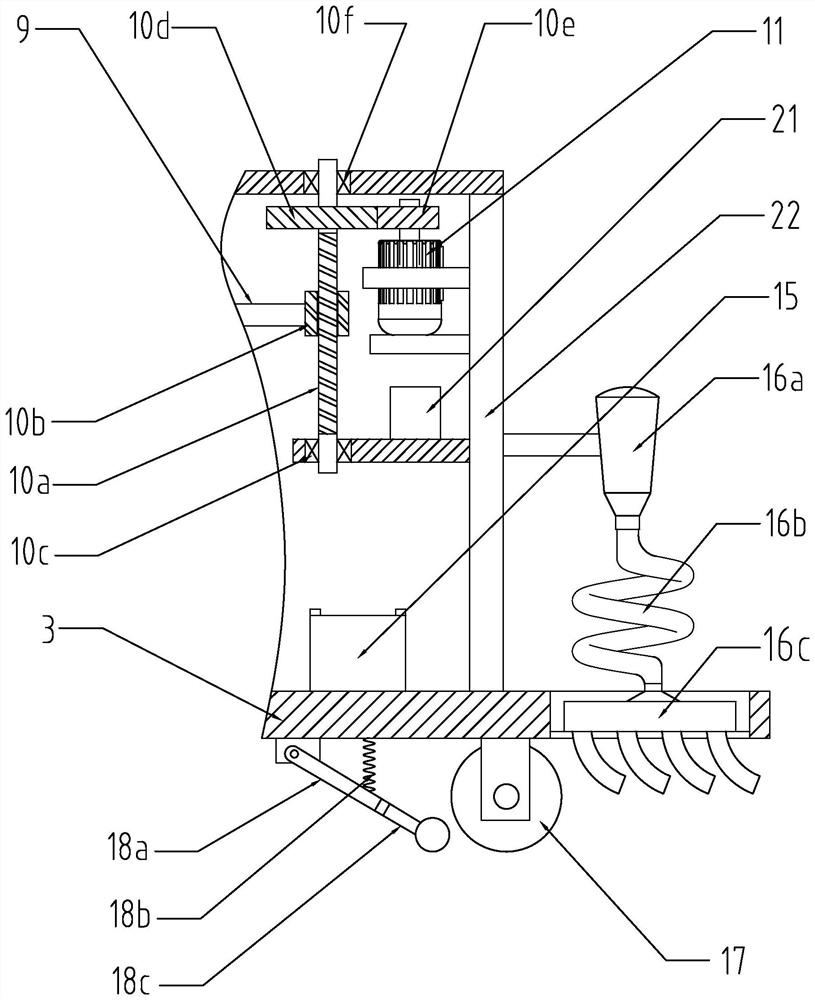

[0046] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0047] This embodiment provides a method for beautifying seams on floor tiles, the construction steps of which are as follows:

[0048] Step 1: Clean up the sundries in the gaps of the floor tiles, and keep the gaps of the floor tiles at a depth of 3mm without debris;

[0049] Step 2: Clean up the sundries and dust on the surface of the tiles, and keep the surface of the tiles clean and free from water stains;

[0050] Step 3: Prepare the beautifying device, turn on the control circuit, control the action of the driving motor, move the extrusion mechanism up, put the beautifying agent cylinder into the heating cylinder, tighten the discharge pipe on the lower part of the beautifying agent cylinder, and squeeze Insert the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com