A method for detecting and controlling the oxidation rate of desulfurization absorption liquid

A technology of absorbing liquid and oxidation rate, which is applied in the direction of chemical instruments and methods, separation methods, control/regulation systems, etc. It can solve the problems of large liquid and gas abundance, inability to optimize energy saving, and difficult operation, so as to improve the surrounding environment The effect of improving convenience, operability, and stable operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

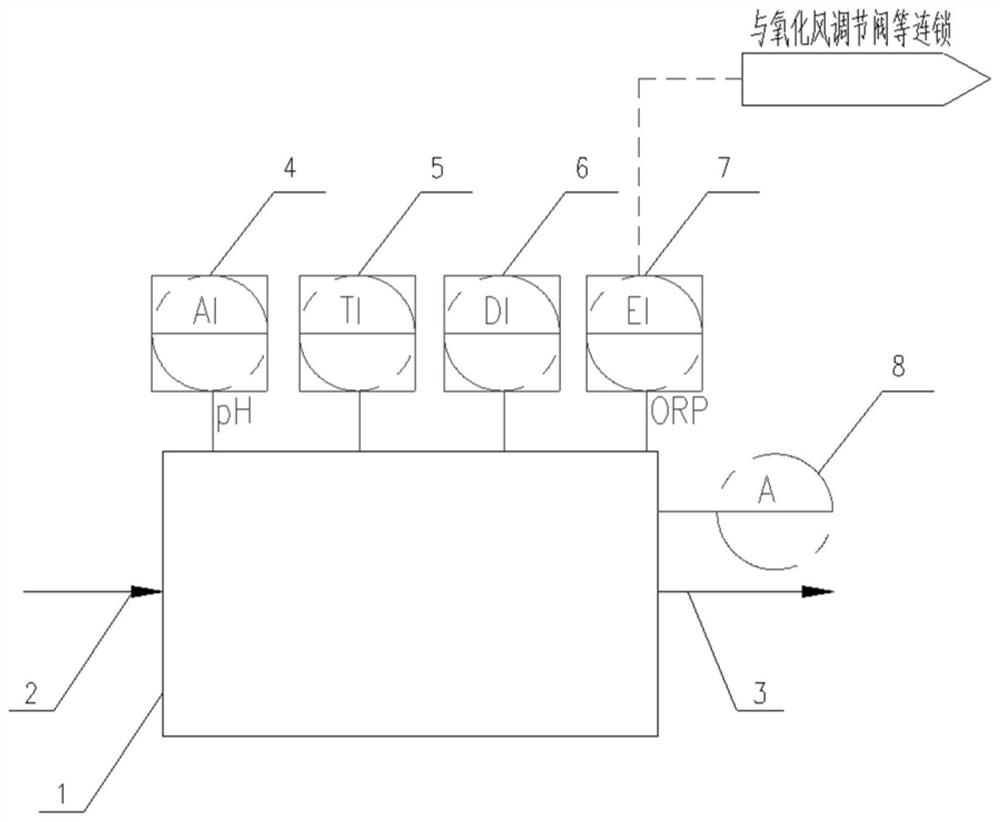

[0043] The method for detecting and controlling the oxidation rate of the desulfurization absorbing liquid is used in the detection and control scheme of the oxidation rate of the absorbing liquid for wet ammonia desulfurization of boiler flue gas.

[0044] One ORP, pH and temperature detector are installed on the outlet pipeline of the absorption circulation pump, and one pressure density meter is installed in the absorption circulation tank.

[0045] When the desulfurization device is in normal operation, the pH of the desulfurization absorption liquid at this measuring point is controlled at 7.0-7.2, the temperature is 47-48°C, and the density is 1.15-1.16. It is required that the oxidation rate of the desulfurization absorption liquid at this measuring point be controlled at 92%-93%.

[0046] The corresponding relationship between the ORP value and the oxidation rate is as follows:

[0047] ORP / mv 213 196 174 154 136 114 97 74 56 36 14 -5 Oxidat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com