Film bulk acoustic resonator, filter and preparation method thereof

A thin-film bulk acoustic wave and resonator technology, applied in impedance networks, electrical components, etc., can solve problems such as device frequency drift, affect device performance, and device temperature rise, so as to avoid temperature rise, reduce process difficulty, and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

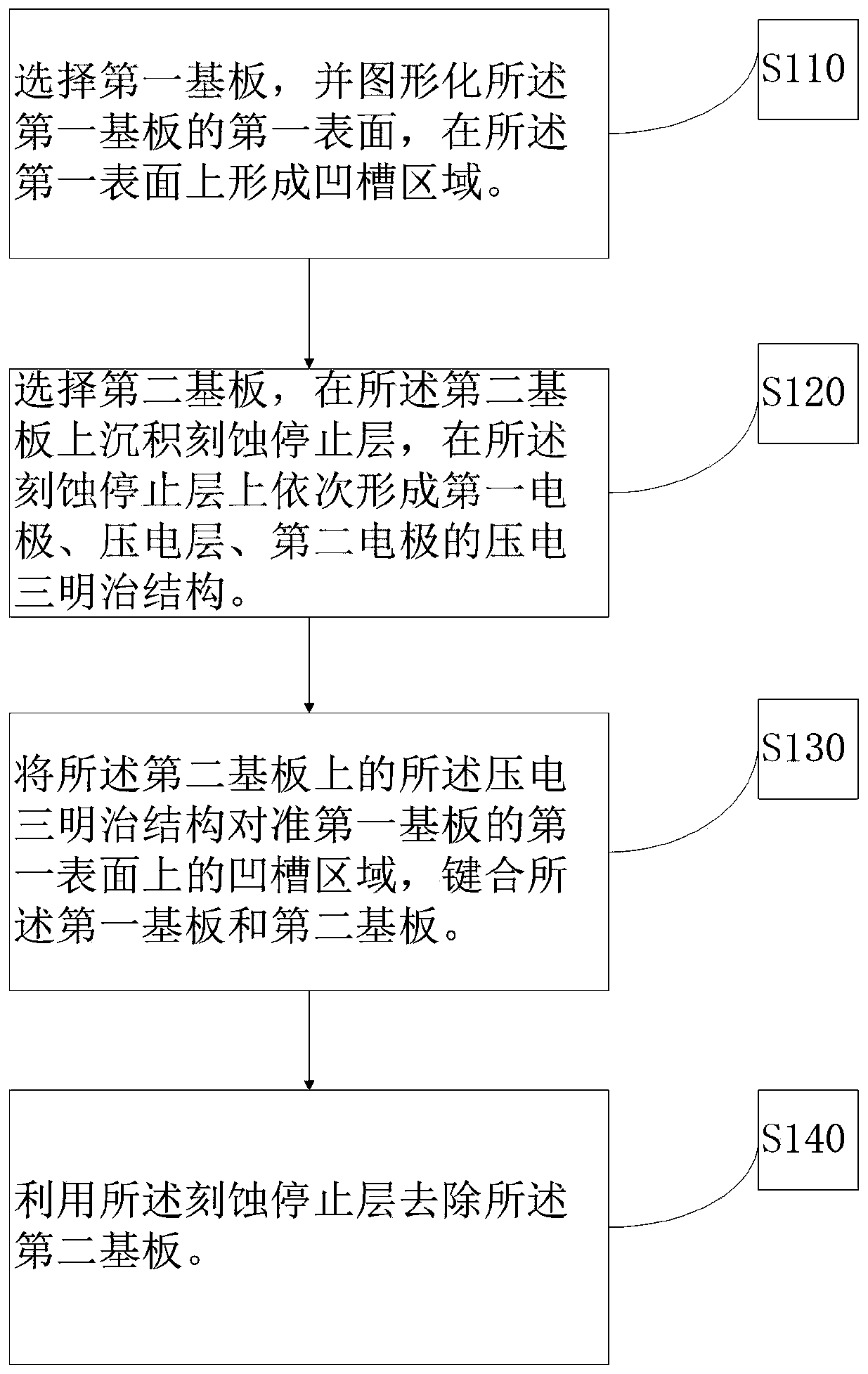

[0041] Such as Figure 1 to Figure 18 Shown is the first embodiment, a thin film bulk acoustic resonator and its preparation method, such as figure 1 As shown, the process flow of the thin film bulk acoustic resonator preparation method includes the following steps:

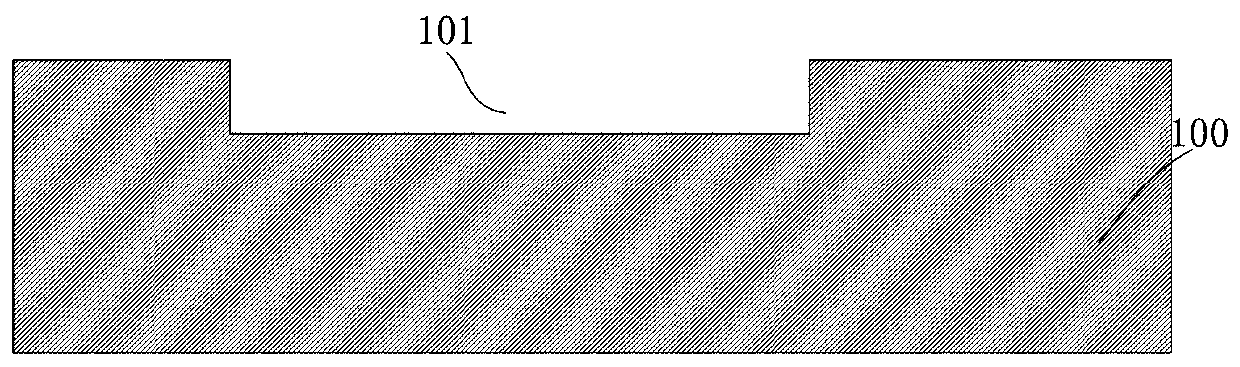

[0042] S110, selecting the first substrate 100, and patterning the first surface of the first substrate 100, forming a groove area 101 on the first surface;

[0043] S120, select the second substrate 300, deposit an etching stop layer 400 on the second substrate 300, and sequentially form a piezoelectric sandwich structure of the first electrode 600, the piezoelectric layer 700, and the second electrode 800 on the etching stop layer 400;

[0044] S130, ali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com