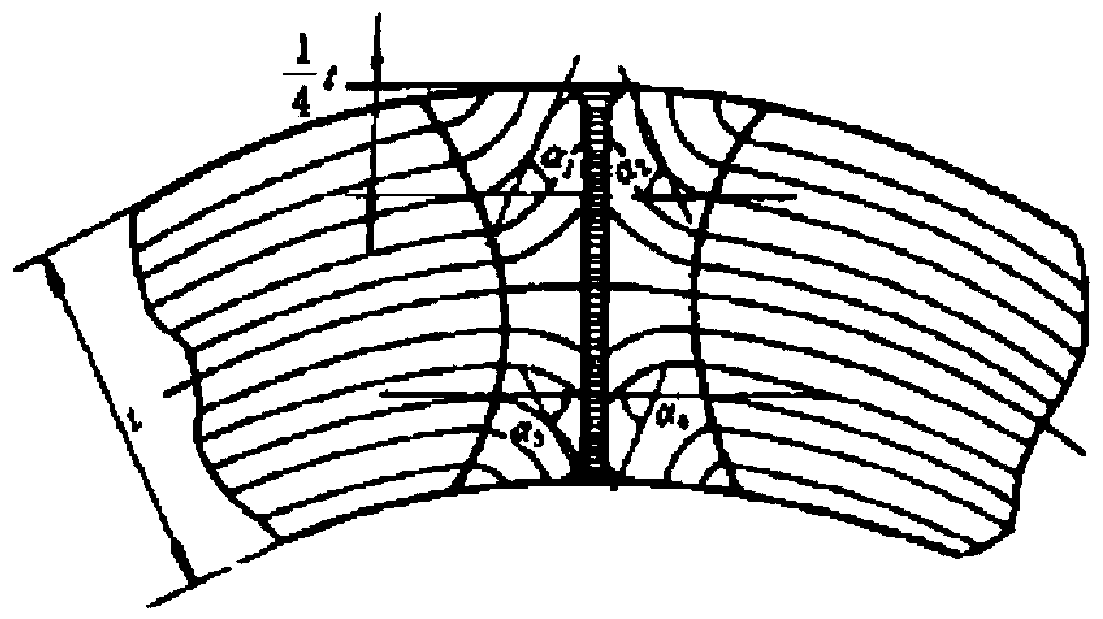

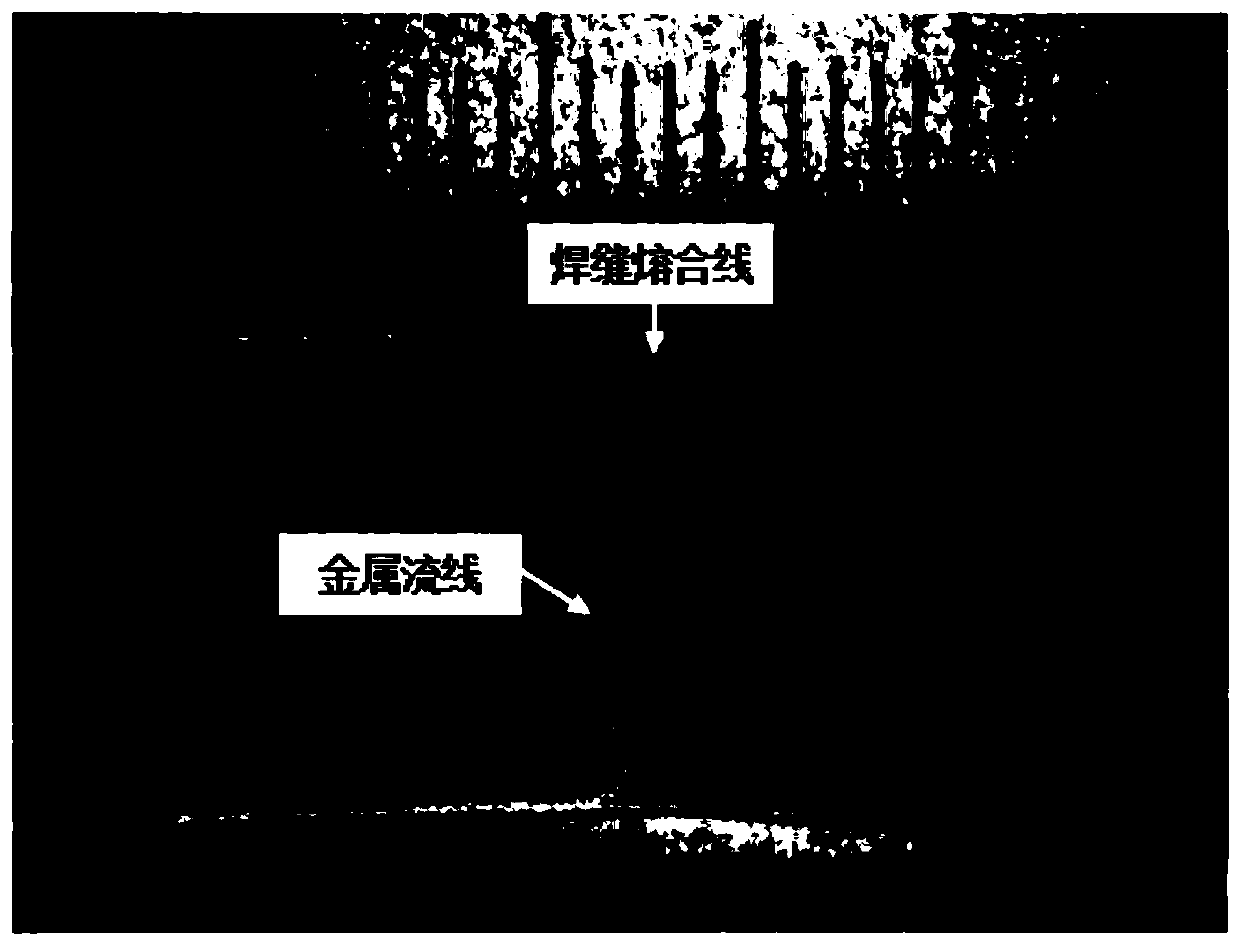

Welded joint metal streamline angle automatic measurement method of high-frequency welded pipe

A technology for welded joints and high-frequency welded pipes, applied in measuring devices, image data processing, instruments, etc., can solve problems such as unclear display of weld metal flow lines, time-consuming and labor-intensive measurement work, etc., to reduce the influence of human factors and achieve accurate The effect of convenient measurement and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] When applying the present invention to display the macroscopic parameters of the high-frequency welded pipe welded joints with steel grade N80-1 casing, the specific steps are:

[0041] 1) Sample preparation: The cross-sectional sample of the welded joint is prepared into a mirror surface, and the specific steps include grinding and polishing.

[0042] Sample polishing is to use different grades of metallographic water sandpaper to polish the test surface of the sample. After replacing the fine sandpaper, the grinding direction is 90° from the previous grinding direction until the previous grinding marks are worn off. The above process needs to keep a certain flow of water as cooling fluid without interruption. The order of the card numbers of the metallographic water sandpaper used in the grinding process is 240#, 600#, 1000#, 1500#.

[0043] Sample polishing treatment includes rough polishing treatment and fine polishing treatment;

[0044] The rough polishing treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com