Bipolar ear low internal resistance lithium ion secondary battery

A technology for secondary batteries and bipolar tabs, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of high battery temperature and high internal resistance, reduce internal resistance, reduce operation difficulty, shorten effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

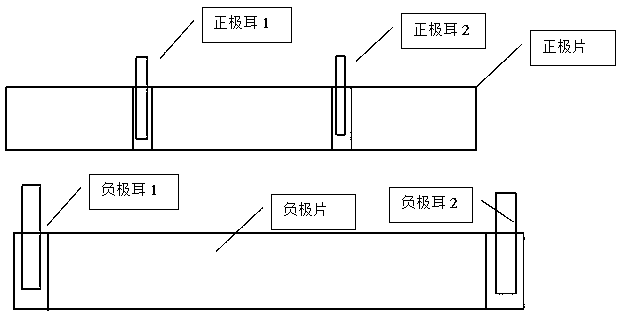

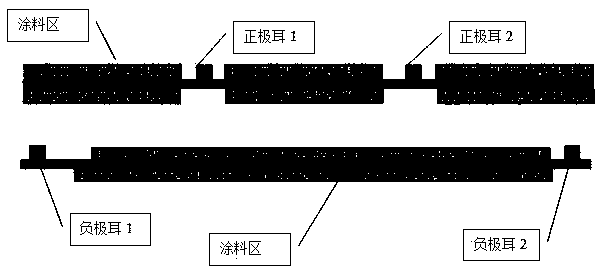

[0030] Example 1, such as figure 1 , 2 As shown, both ends of the positive electrode are coating areas, and a 5-25mm wide position is left in the 5%-40% area of the positive electrode. The positive electrode tab 2 is set after the 5-25mm wide position is not coated with positive electrode slurry, and the negative electrode tab 1 and negative electrode tab 2 are respectively set at the positions left at both ends of the negative electrode sheet without negative electrode slurry coated.

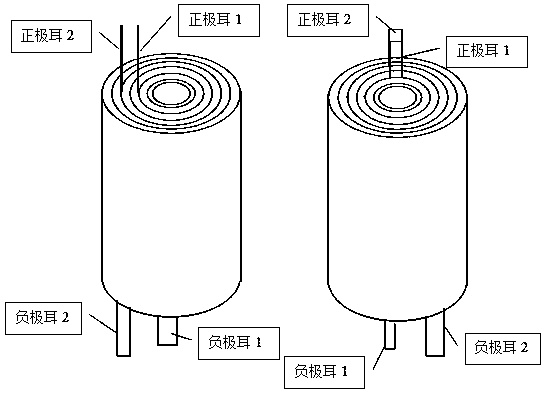

[0031] The positive electrode sheet, negative electrode sheet, and separator are stacked and wound separately to form a core, such as image 3 As shown, the two tabs on the positive electrode sheet are located on the same side of the winding core and the two tabs should preferably be in an overlapping position. The misalignment deviation should be less than 8mm if they cannot be overlapped. The two tabs on the negative electrode sheet should preferably be in a non-overlapping position.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com