Peach-flavored yoghourt and preparation method thereof

A technology for yogurt and strains, which is applied to milk preparations, bacteria and dairy products used in food preparation, etc., can solve the problems of residual milky smell of yogurt, discomfort for drinkers, and the limit of microorganisms does not meet the standard requirements. The effect of rich taste and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

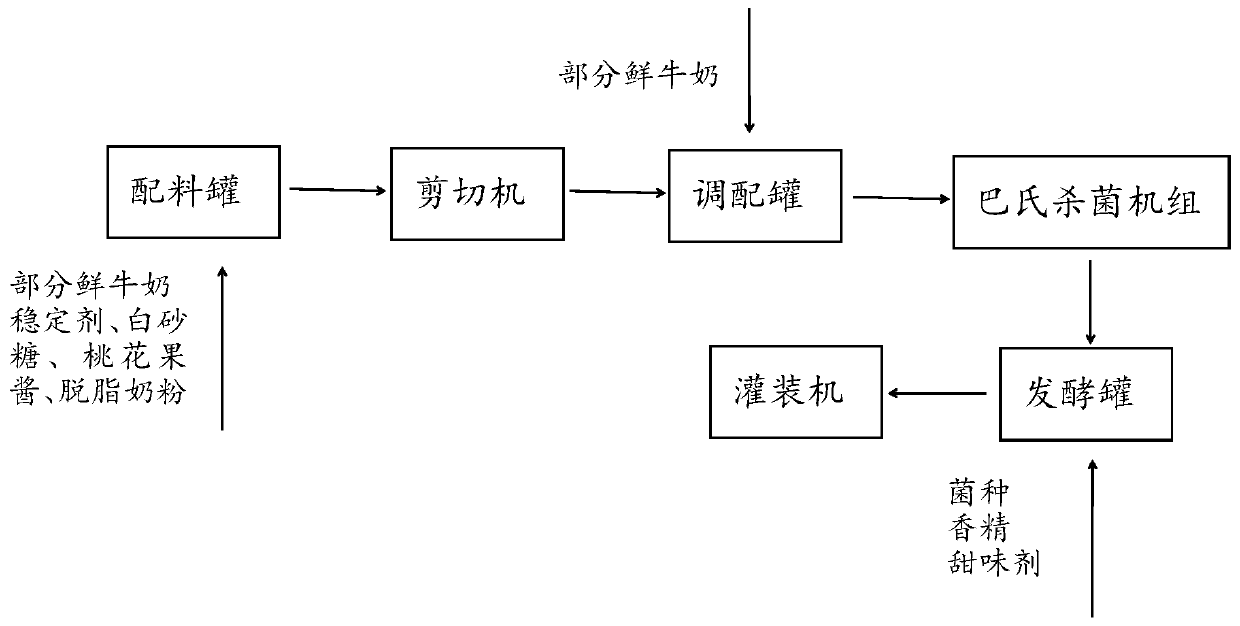

[0033] In addition, the present invention also provides a preparation method of peach-flavored yoghurt, comprising the following steps:

[0034] (1) Add skimmed milk powder, stabilizer, white granulated sugar and peach blossom jam to half of the fresh milk as claimed in claim 1, then shear to obtain the base solution;

[0035] (2) Add remaining fresh milk to the above basic solution, then homogenize and sterilize to obtain a semi-finished product solution;

[0036] (3) Add strains, peach blossom essence and sweetener to the above-mentioned semi-finished product solution to ferment, and obtain yoghurt after refrigeration.

[0037] Further, in step (1), before adding skimmed milk powder, stabilizer, white granulated sugar and peach blossom jam to the fresh milk, first heat the fresh milk to 65-75°C in a plate heat exchanger; the shearing time 15 to 20 minutes; after the shearing is completed, cool the base solution to below 15°C in a plate heat exchanger.

[0038] Further, aft...

Embodiment 1

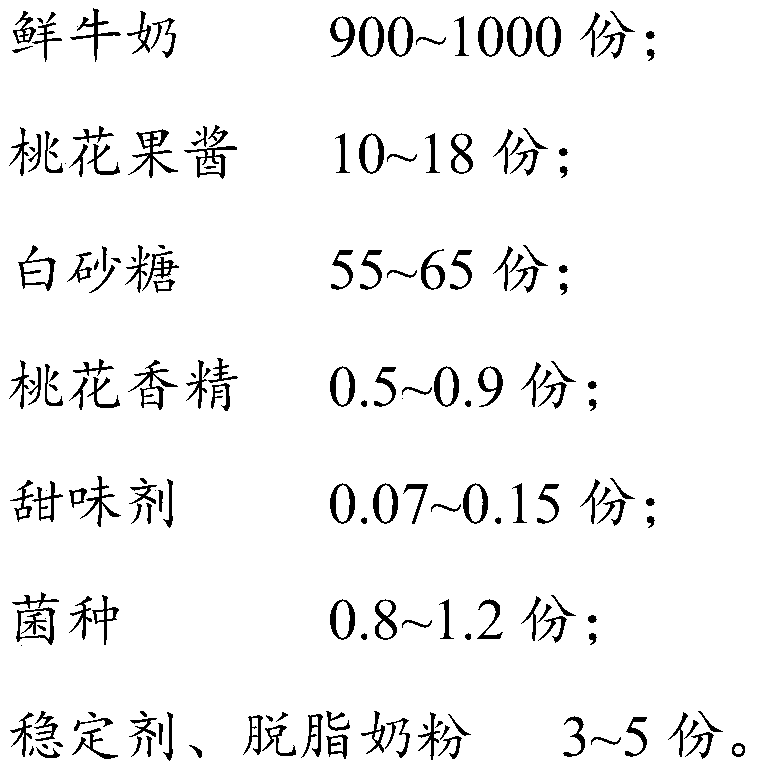

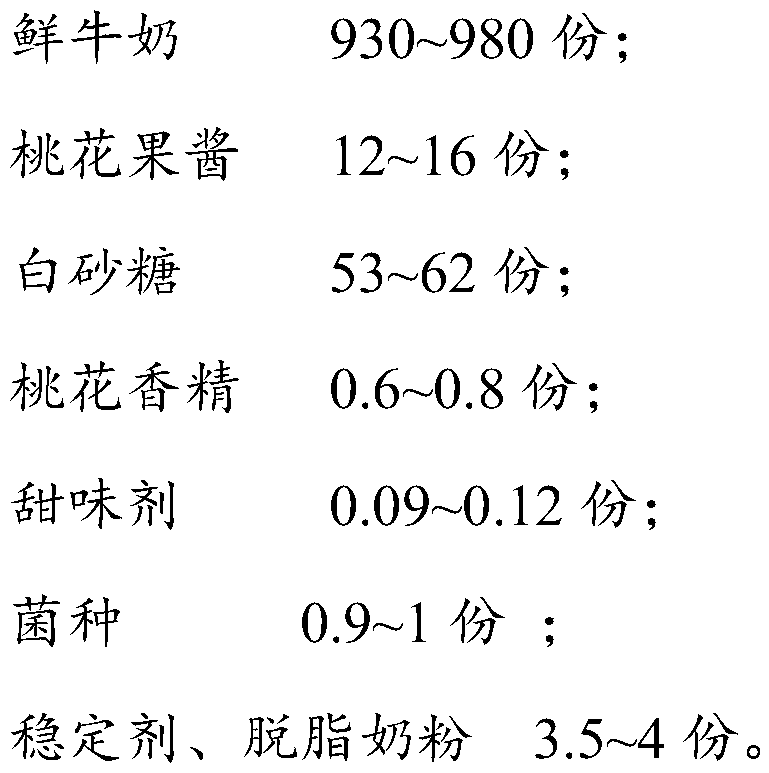

[0043] First weigh 950Kg of fresh milk, 15Kg of peach blossom jam, 58Kg of white sugar, 0.8Kg of peach blossom essence, 0.1Kg of acesulfame potassium, 1Kg of strains, 2Kg of pectin and 2Kg of skimmed milk powder for later use;

[0044] Pour half of the above quality of fresh milk into the batching tank, heat up to 70°C through a plate heat exchanger, then slowly add the above-mentioned quality of skimmed milk powder, pectin, white sugar and peach blossom jam into the fresh milk batching tank, and stir Evenly, open the shearing machine, close it after shearing for 15 minutes, cool the material to 15°C through the plate heat exchanger, and discharge it to the blending tank;

[0045] Add the remaining fresh milk into the blending tank, turn on the mixer, and stir for more than 10 minutes for later use; the above-mentioned stirred materials are homogenized and sterilized by the pasteurization unit, and the homogenization adopts the second homogenization, and the pressure of the fir...

Embodiment 2

[0048] First weigh 980Kg of fresh milk, 12Kg of peach blossom jam, 56Kg of white sugar, 0.8Kg of peach blossom essence, 0.12Kg of acesulfame potassium, 1.1Kg of strains, 3Kg of gelatin and 1Kg of skimmed milk powder for later use;

[0049] Pour half of the above-mentioned quality of fresh milk into the batching tank, heat up to 65°C through a plate heat exchanger, then slowly add the above-mentioned quality of skimmed milk powder, gelatin, white sugar and peach blossom jam into the fresh milk batching tank, and stir evenly , open the shearing machine, close it after shearing for 20 minutes, cool the material to 15°C through the plate heat exchanger, and discharge it to the blending tank;

[0050] Add the remaining fresh milk into the blending tank, turn on the mixer, and stir for more than 10 minutes for later use; the above-mentioned stirred materials are homogenized and sterilized by the pasteurization unit, and the homogenization adopts the second homogenization, and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com