Ferrous aluminate and strontium aluminate containing high-temperature lubricating composite material and preparation method thereof

A ferrous aluminate and composite material technology, applied in the field of lubricating materials, can solve the problems of friction and wear properties easily affected by temperature, low shear strength bearing capacity, loss of lubrication, etc., and achieve low raw material cost and low wear rate , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

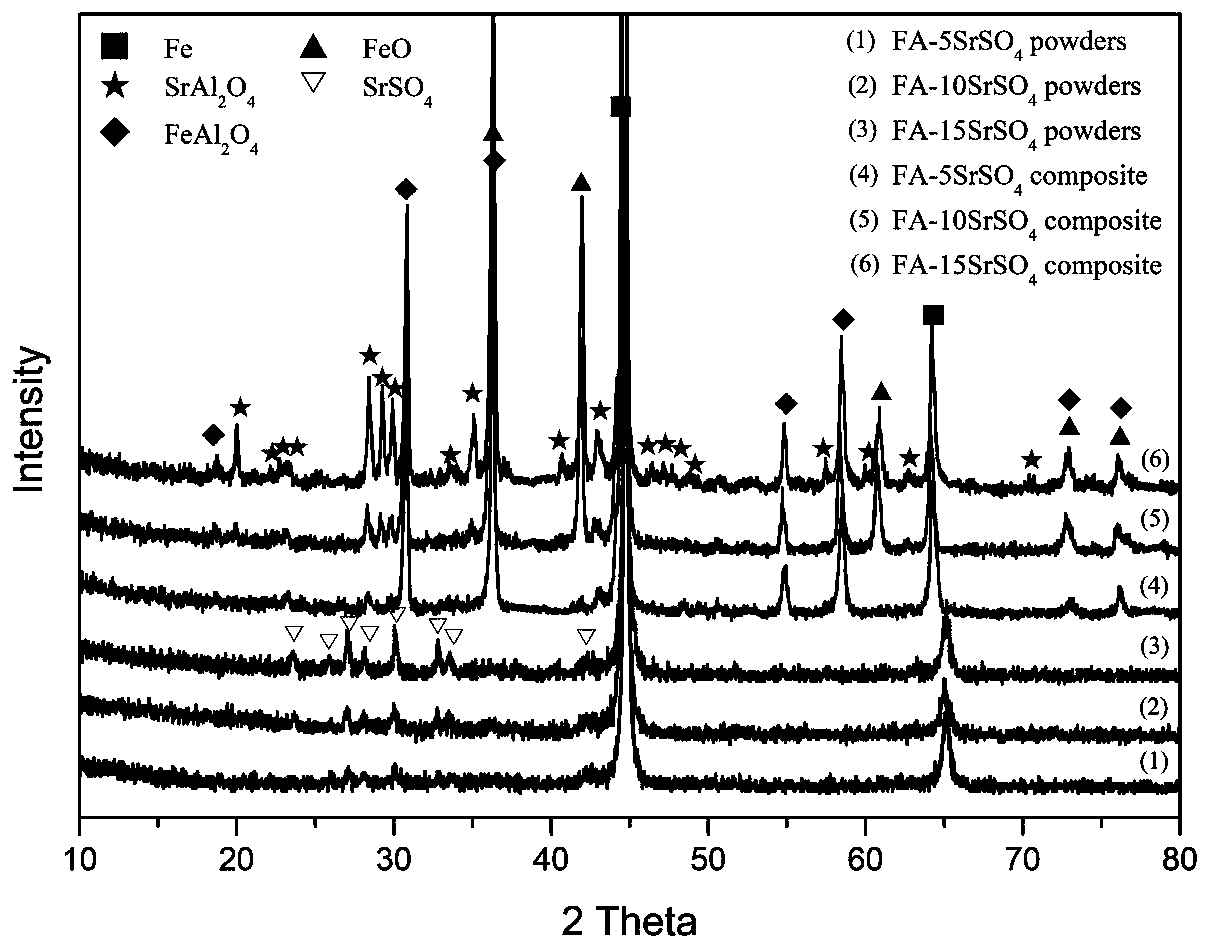

[0031] The present invention provides a method for preparing the above-mentioned high-temperature lubricating composite material containing ferrous aluminate and strontium aluminate, comprising the following steps:

[0032] (1) Fe powder is mixed with Al powder, and ball milling is carried out to obtain iron-aluminum solid solution;

[0033] (2) mixing the iron-aluminum solid solution with strontium sulfate, and performing ball milling to obtain a mixed powder;

[0034] (3) performing pre-pressing treatment and hot-pressing sintering on the mixed powder in sequence to obtain a high-temperature lubricating composite material containing ferrous aluminate and strontium aluminate.

[0035] The invention mixes Fe powder and Al powder and performs ball milling treatment to obtain iron-aluminum solid solution. The present invention has no special requirements on the mixing method, and the Fe powder and the Al powder can be uniformly mixed using a mixing method well known to those sk...

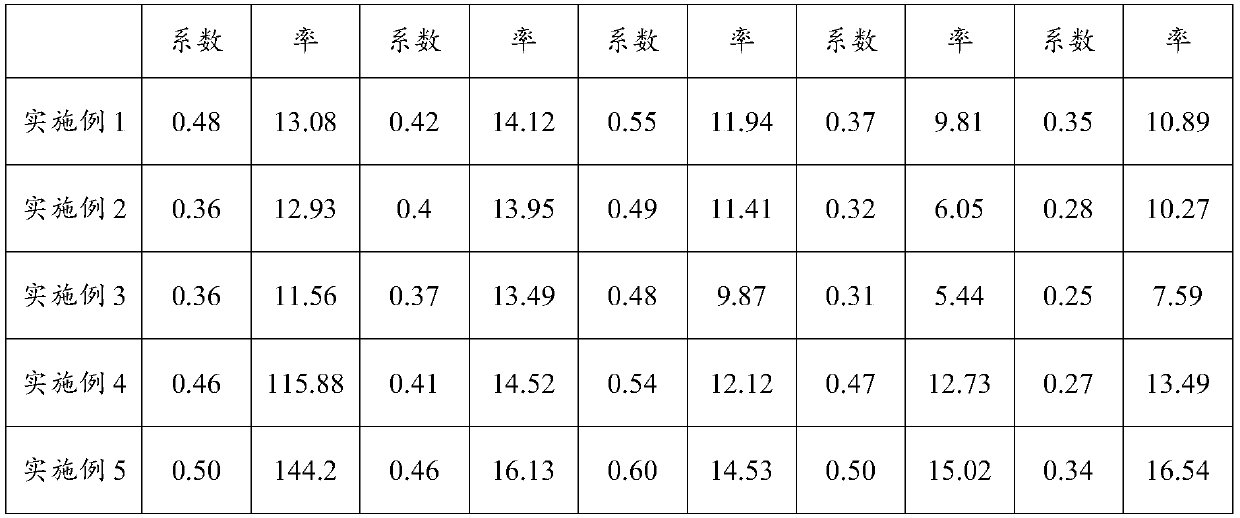

Embodiment 1

[0042] A ferrous aluminate (FeAl 2 o 4 ) and strontium aluminate (SrAl 2 o 4 ) of high-temperature lubricating composite materials, by mass percentage, including the following components: SrSO 4 : 3%, Fe powder: 83.61%, Al powder: 13.39%.

[0043] The preparation method comprises the following steps:

[0044] (1) Mix Fe powder and Al powder, add 100mL of absolute ethanol to the planetary high-energy ball mill, use wet ball milling process to ball mill Fe powder and Al powder, ball mill time 10h, speed 250r / min, ball material The ratio is 10:1, and iron-aluminum solid solution is obtained;

[0045] (2) Fe-Al solid solution and SrSO 4 Mix the powders, add 100mL of absolute ethanol for ball milling, the ball milling time is 10h, the speed is 250r / min, and the mixed powder is obtained;

[0046] (3) Put the above-mentioned mixed powder into a graphite mould, use a jack to carry out manual preloading, the preloading pressure is 10MPa, and the holding time is 2min;

[0047] (...

Embodiment 2

[0051] A ferrous aluminate (FeAl 2 o 4 ) and strontium aluminate (SrAl 2 o 4 ) of high-temperature lubricating composite materials, by mass percentage, including the following components: SrSO 4 : 5%, Fe powder: 81.89%, Al powder: 13.11%.

[0052] The preparation method comprises the following steps:

[0053] (1) Mix Fe powder and Al powder, add 100mL of absolute ethanol to the planetary high-energy ball mill, use wet ball milling process to ball mill Fe powder and Al powder, ball milling time 15h, speed 300r / min, ball material The ratio is 5:1, and iron-aluminum solid solution is obtained;

[0054] (2) Fe-Al solid solution and SrSO 4 Mix the powders, add 100mL of absolute ethanol for ball milling, the ball milling time is 15h, the speed is 300r / min, and the mixed powder is obtained;

[0055] (3) Put the above-mentioned mixed powder into a graphite mould, use a jack to carry out manual preloading, the preloading pressure is 10MPa, and the holding time is 2min;

[0056]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com