Fiber reinforced PBT/ASA (polybutylece terephthalate/acrylonitrile styrene acrylate) alloy material with good weldability and preparation method of material

A fiber-reinforced and alloy material technology, applied in the field of fiber-reinforced PBT/ASA alloy materials and their preparation, to achieve the effects of improved compatibility, wide melting range, and good heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

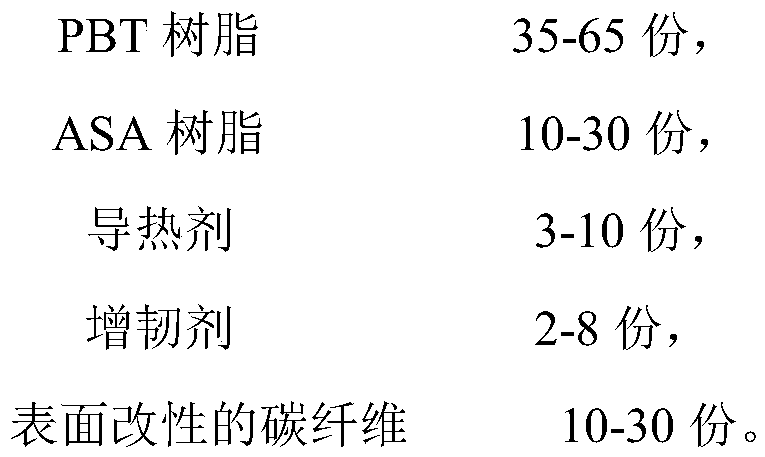

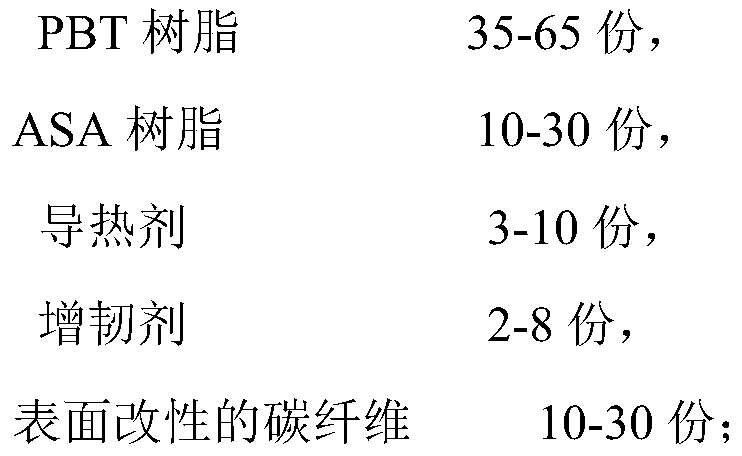

Method used

Image

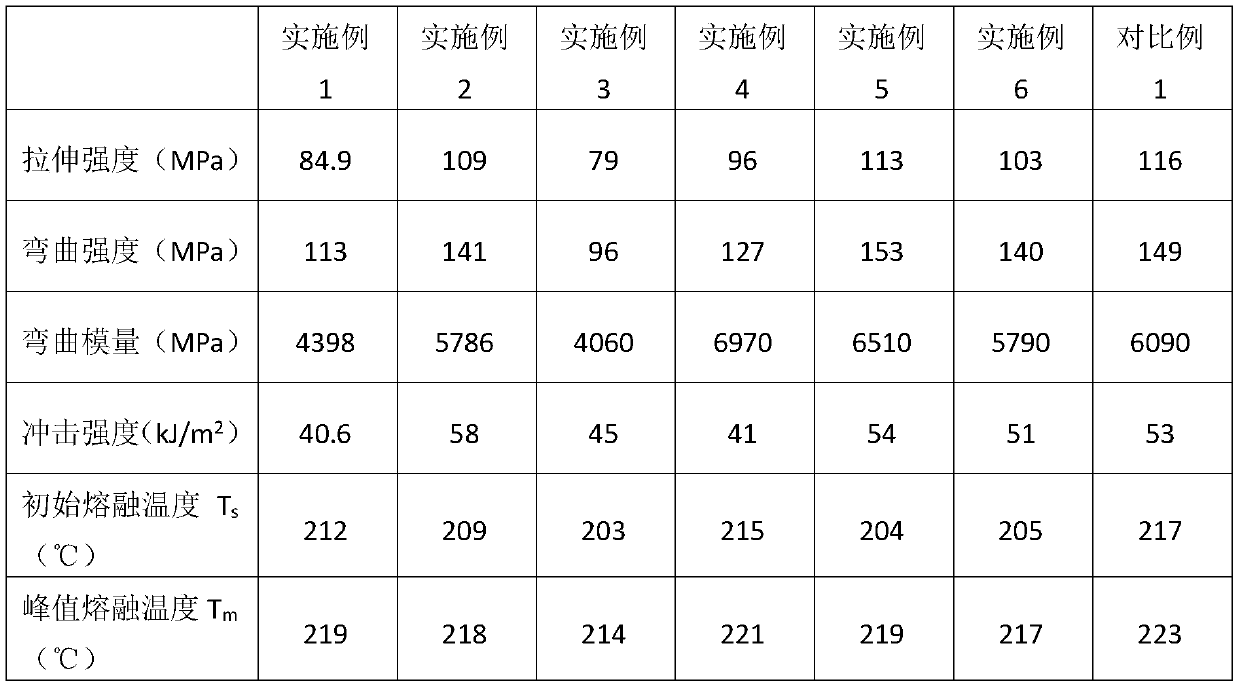

Examples

Embodiment 1

[0042] Take by weighing PBT resin, ASA resin, heat conducting agent, toughening agent by the embodiment 1 data shown in table 1, mix homogeneously, obtain mixed raw material:

[0043] The dried mixed raw materials are placed in the main feeding bin of a tightly meshed co-rotating twin-screw extruder, and fed into the barrel of the extruder through the feeding screw; the surface-modified carbon fiber is placed in In the side feeding bin of the extruder screw, it is fed into the barrel of the extruder through the feeding screw. The diameter of the screw extruder used is 36mm, the length-to-diameter ratio L / D is 44, and the temperature of each zone of the main barrel from the feeding port to the exit of the machine head is set as: 160°C, 220°C, 230°C, 235°C, 240°C , 240°C, 240°C, the speed of the main machine is 250 rpm, and the above-mentioned fiber-reinforced PBT / ASA alloy material with good weldability is obtained after melt extrusion, granulation, drying and other processes. ...

Embodiment 2

[0047] Take by weighing PBT resin, ASA resin, heat conducting agent, toughening agent by the embodiment 2 data shown in table 1, mix homogeneously, obtain mixed raw material:

[0048] The dried mixed raw materials are placed in the main feeding bin of a tightly meshed co-rotating twin-screw extruder, and fed into the barrel of the extruder through the feeding screw; the surface-modified carbon fiber is placed in In the side feeding bin of the extruder screw, it is fed into the barrel of the extruder through the feeding screw. The diameter of the screw extruder used is 36mm, the length-to-diameter ratio L / D is 44, and the temperature of each zone of the main barrel from the feeding port to the exit of the machine head is set as: 160°C, 220°C, 230°C, 235°C, 240°C , 240°C, 240°C, the speed of the main machine is 250 rpm, and the above-mentioned fiber-reinforced PBT / ASA alloy material with good weldability is obtained after melt extrusion, granulation, drying and other processes. ...

Embodiment 3

[0050] Take by weighing PBT resin, ASA resin, heat conducting agent, toughening agent by the data of embodiment 3 shown in table 1, mix homogeneously, obtain mixed raw material:

[0051] The dried mixed raw materials are placed in the main feeding bin of a tightly meshed co-rotating twin-screw extruder, and fed into the barrel of the extruder through the feeding screw; the surface-modified carbon fiber is placed in In the side feeding bin of the extruder screw, it is fed into the barrel of the extruder through the feeding screw. The diameter of the screw extruder used is 36mm, the length-to-diameter ratio L / D is 44, and the temperature of each zone of the main barrel from the feeding port to the exit of the machine head is set as: 160°C, 220°C, 230°C, 235°C, 240°C , 240°C, 240°C, the speed of the main machine is 250 rpm, and the above-mentioned fiber-reinforced PBT / ASA alloy material with good weldability is obtained after melt extrusion, granulation, drying and other processe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com