Preparation method and device of a porous surface structure fiber

A technology of structural fiber and porous surface, applied in the field of melt-blown textile, can solve the problems of limited application, complex preparation process, environmental pollution, etc., and achieve the effects of high specific surface area, controllable pore size, and simple and efficient preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with specific embodiment (but not limited to enumerated embodiment) and accompanying drawing; Modifications and changes in various forms and structures can be made, and these equivalent forms based on the present invention also fall within the protection scope of the claims of the present application.

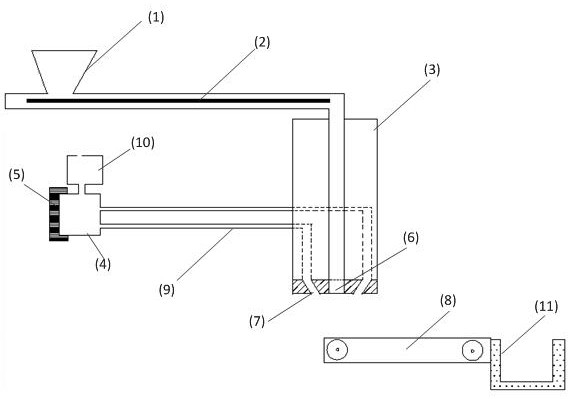

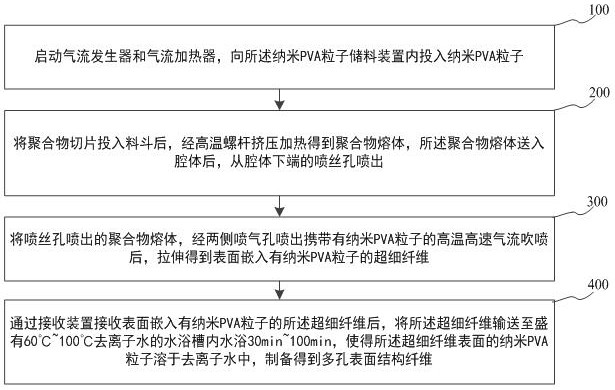

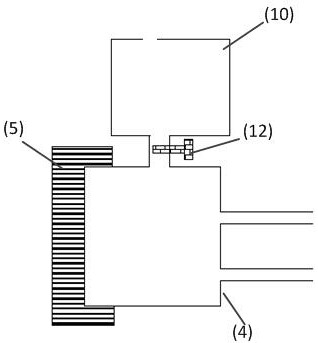

[0031] figure 1 It is a schematic diagram of a device for preparing porous surface structure fibers according to an exemplary embodiment, including a hopper (1), a high-temperature screw (2), a chamber (3), an airflow generator (4), and an airflow heater (5), jet hole (7), spinneret hole (6) and receiving device (8), characterized in that:

[0032] The hopper (1) is arranged above one end of the high-temperature screw (2), and the other end is connected to the cavity (3); the spinneret hole (6) is set at the lower end of the cavity (3), In addition, the left and right sides of the spinneret hole (6) are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com