PCB film residue reduction treatment system and method based on microwave thermal dehydration

A microwave processing system and technology of the processing system, which are applied in the drying cargo processing, heating devices, lighting and heating equipment, etc., can solve the problems of low dehydration efficiency, high cost of outsourcing treatment of membrane slag, and limited water volume, etc., and achieve dehydration efficiency. High, no secondary pollution, and the effect of saving treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

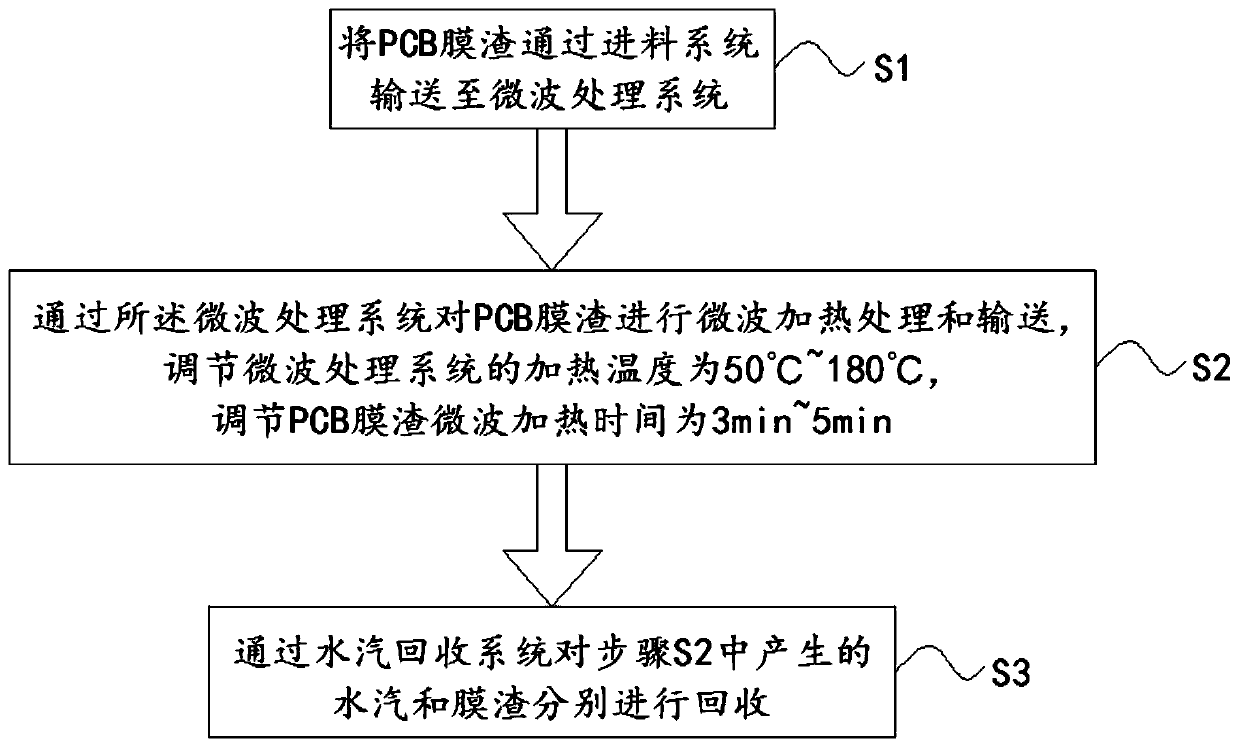

[0028] refer to figure 1 with figure 2 , figure 1 It is a structural diagram of the PCB film slag reduction treatment system of the present invention; figure 2 It is a flow chart of the PCB film slag reduction treatment method of the present invention;

[0029] A PCB film slag reduction treatment system based on microwave thermal dehydration proposed in this embodiment includes:

[0030] Feeding system: used to transport PCB film slag,

[0031] Microwave processing system: connected to the discharge end of the feeding system, used for microwave processing of PCB film slag, the microwave processing system includes a reaction chamber 21, and a A conveying device 22 for PCB film slag, at least one microwave generator 23 for microwave treatment of PCB film slag and at least one temperature transmitter 24 for detecting the temperature in the reaction chamber 21 are also installed in the reaction chamber 21 ,

[0032] Water vapor recovery system: connected to the water vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com