Method for measuring refractive index by using conical coreless optical-fiber-cascaded hollow-core optical fiber structure

A technology of coreless optical fiber and hollow-core optical fiber, which is applied in the field of measuring refractive index by using tapered coreless optical fiber cascaded hollow-core optical fiber structure, which can solve the problems of poor stability, temperature crosstalk, low sensitivity and resolution, etc., and achieve high sensitivity , low temperature sensitivity, and the effect of simplifying the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The above-mentioned contents of the present invention are described in further detail below through the embodiments, but this should not be interpreted as the scope of the above-mentioned themes of the present invention being limited to the following embodiments, and all technologies realized based on the above-mentioned contents of the present invention all belong to the scope of the present invention.

[0017] (1) Tapered coreless fiber cascaded hollow-core fiber structure measurement system for refractive index

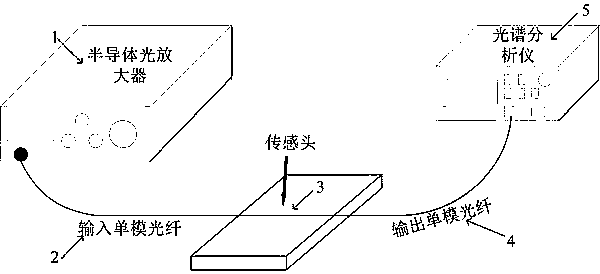

[0018] The optical fiber refractive index measurement system is composed of a semiconductor optical amplifier 1, an input single-mode fiber 2, a tapered coreless fiber cascaded hollow-core fiber 3, an output single-mode fiber 4 and a spectrum analyzer 5.

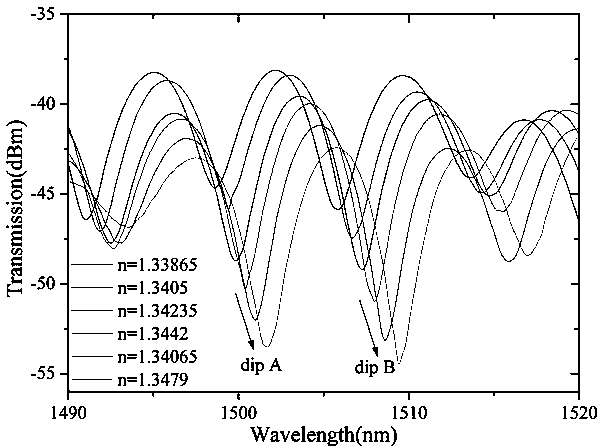

[0019] (2) Measurement of Refractive Index

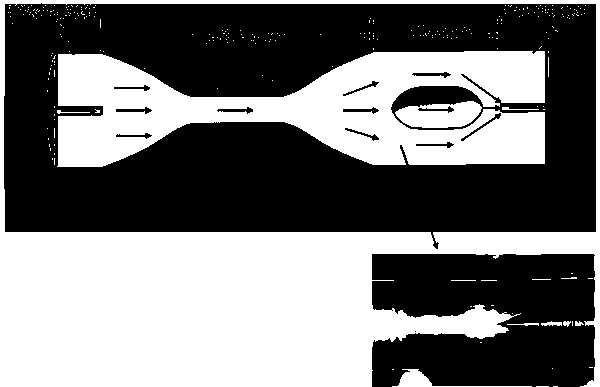

[0020] Broadband light (wavelength range from 1200-1700nm) comes out of the semiconductor optical amplifier through the input single-mode fiber and the tapered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com