Semi-fine numerical simulation method for node of prestressed fabricated concrete structure

A concrete structure, numerical simulation technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of imprecise simulation, difficult convergence of nonlinear analysis, and large modeling workload, etc. Simulation accuracy, saving simulation steps and time, ensuring the effect of the simulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

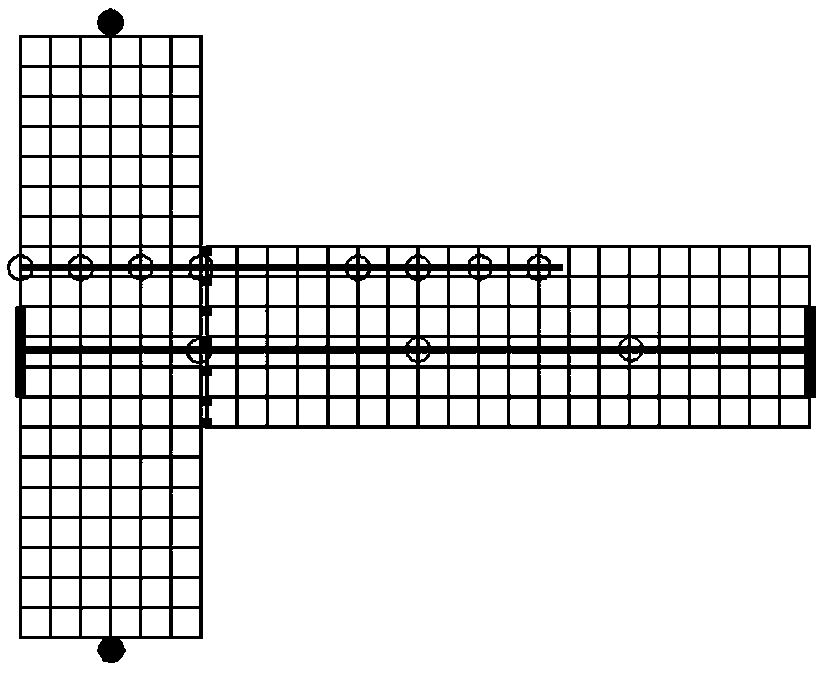

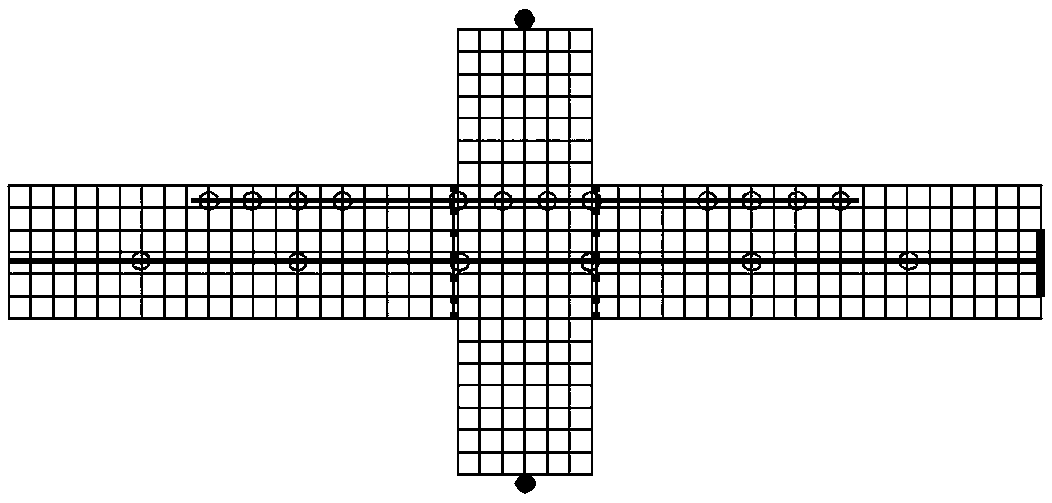

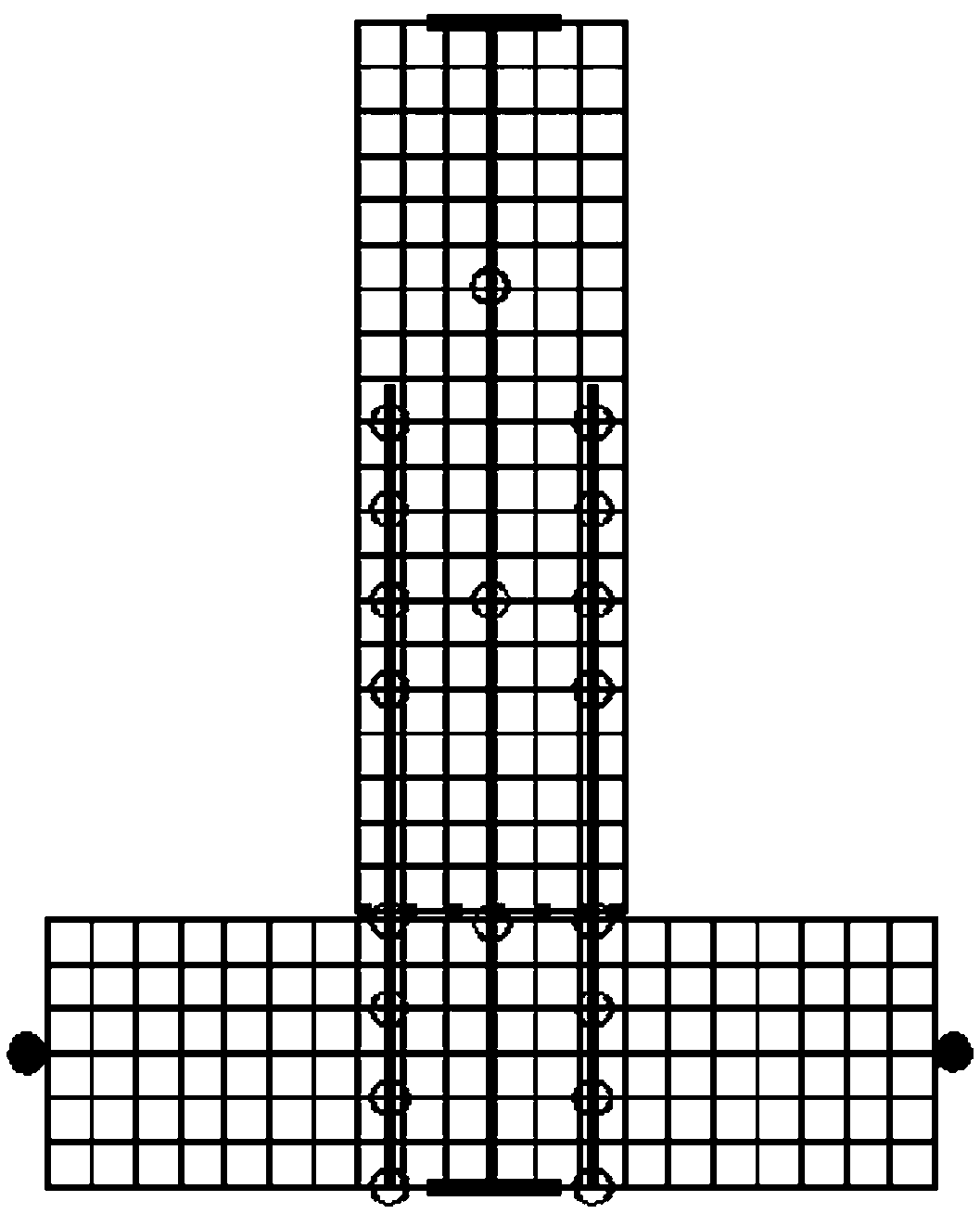

[0032] figure 1 and figure 2 Schematic diagrams of beam-column side nodes, beam-column middle nodes, and column foot node models established by using ABAQUS software according to the method described in the present invention are given respectively, wherein the hollow circles represent the bonded springs between energy-dissipating steel bars and concrete elements, and the solid circles represent the model Boundary constraints, bold lines represent energy-dissipating steel bars (section ends) and prestressed tendons (section middle), and black squares represent contact elements; taking the establishment of beam-column edge node models as an example, the specific operation steps are as follows:

[0033] 1) Construct the contour line of the beam-column edge joint in the software according to the actual beam-column joint size, and divide the grid unit inside the contour line; 2) Input the concrete or steel bar material and parameters in the corresponding unit grid, among which the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com