Insulator steel cap and manufacturing method

A technology of insulators and steel caps, applied in the field of steel caps and production of electric porcelain insulators, can solve the problems of uneven thickness of steel caps, unbalanced welding, large waste, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The object of the invention is given by the following examples:

[0033] The first step is to use 235 steel plates to cut off the cylinder material and the traction hanging button material respectively;

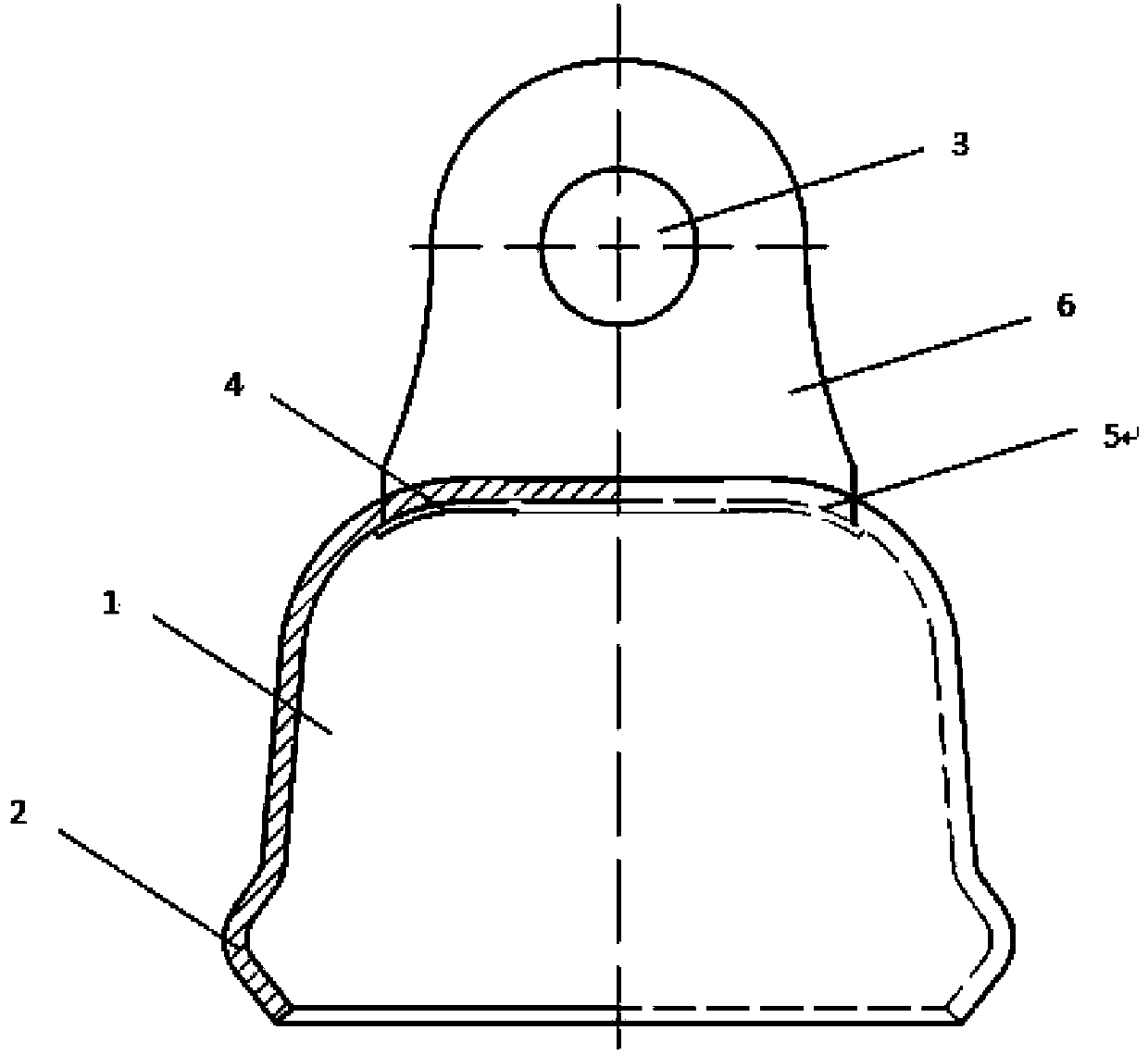

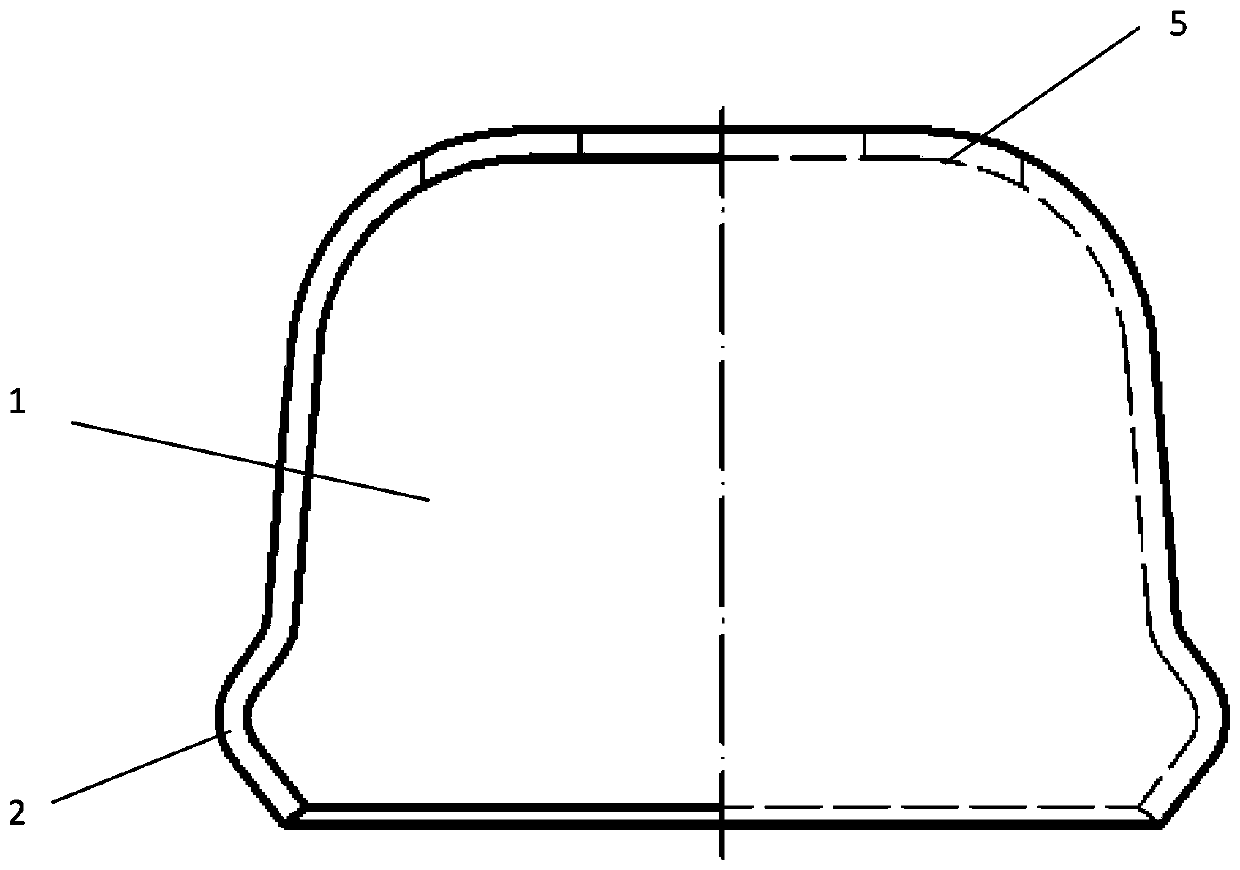

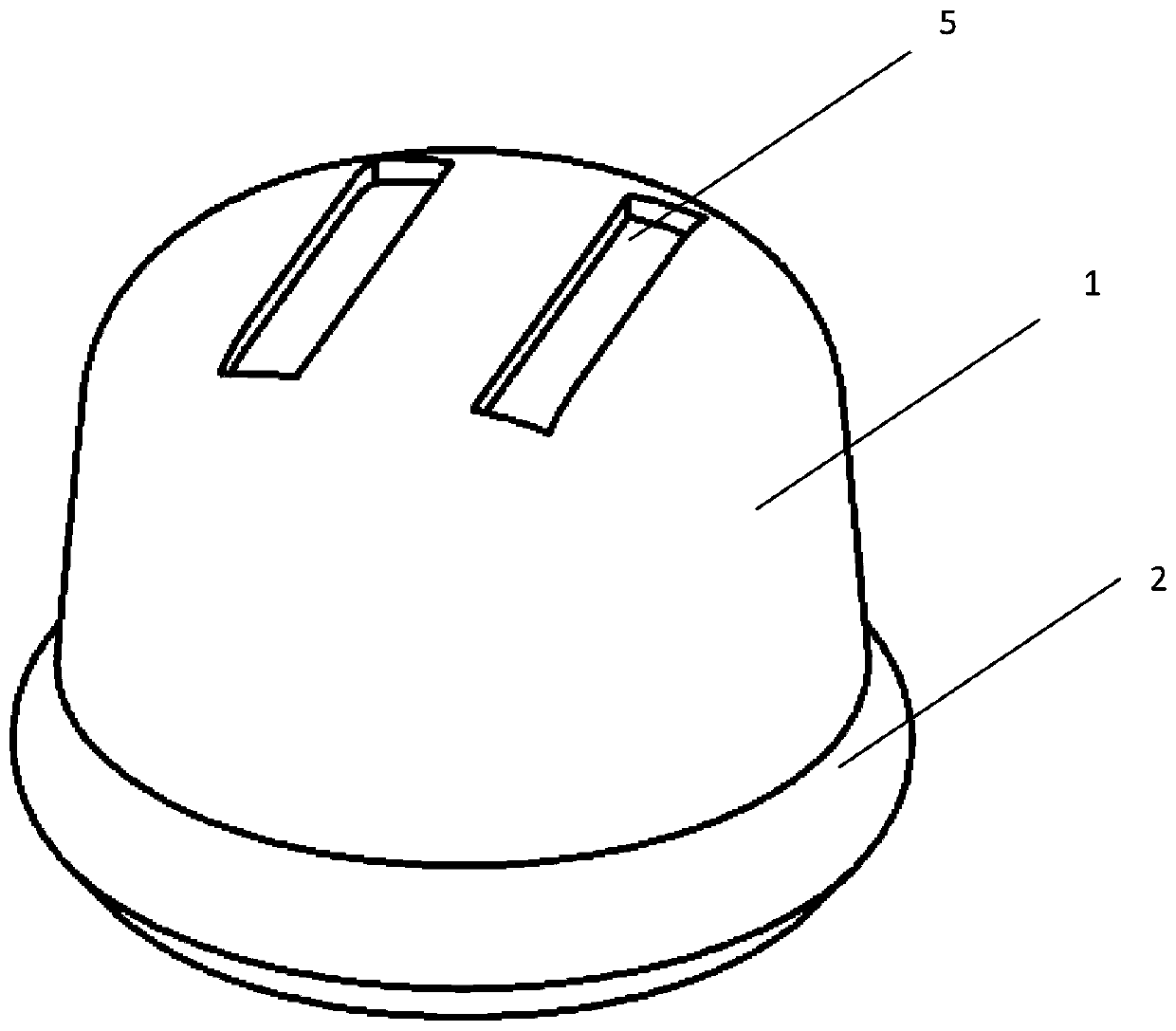

[0034] In the second step, put the cut material into a stamping machine dedicated to the thermal shock method for stamping; the traction hook 6 is punched and formed at one time, and when the traction hanger 6 is inserted into the groove from the side of the cylinder body 1, the riveting foot Processed into "I" shape; cylinder body 1 is stamped twice; the first time is stamped into a stalactite-shaped cylinder blank, and at the same time, two grooves 5 are pressed out on the upper end of cylinder body 1; the second time is with a special arc-expanding stamping device Stamping the lower end of the cylinder so that the lower end of the cylinder forms a circular arc dimple 2;

[0035] The third step is to assemble the stamped cylinder 1 and the traction hook 6; firstly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com