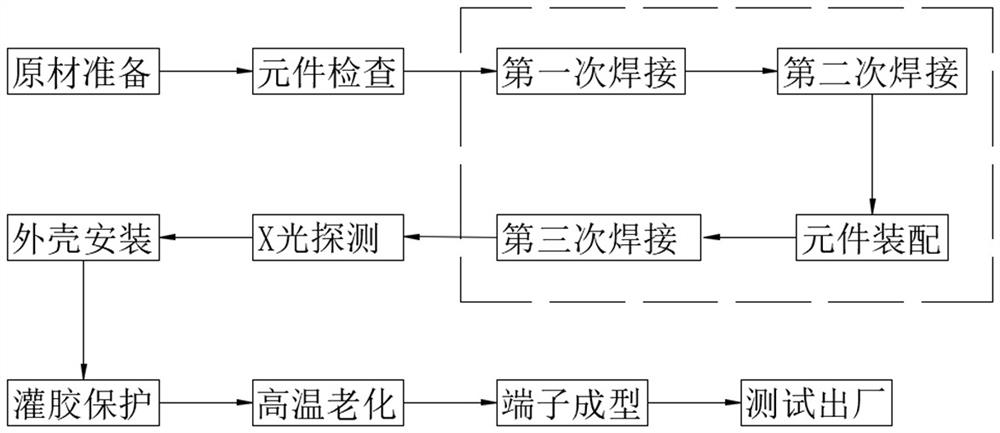

A new preparation process of busbar based on igbt module

A preparation process and busbar technology, applied in the field of new busbar preparation technology, can solve the problems of reducing the cleaning pressure of the subsequent process, reducing the amount of solder paste, reducing the cost and assembly, etc., achieving high market promotion value, reducing cleaning pressure, The effect of stable welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

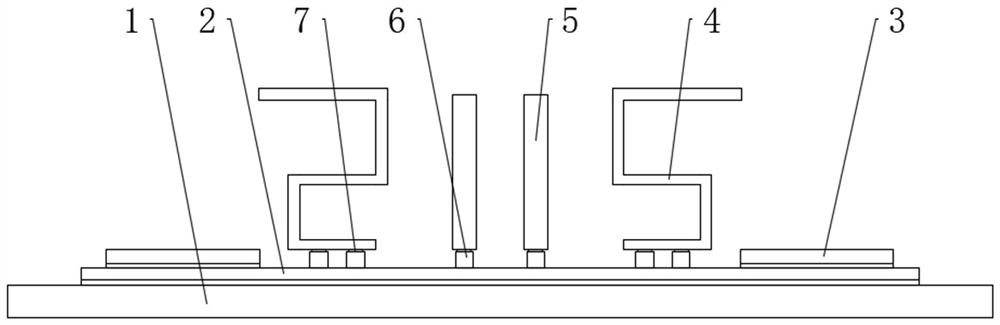

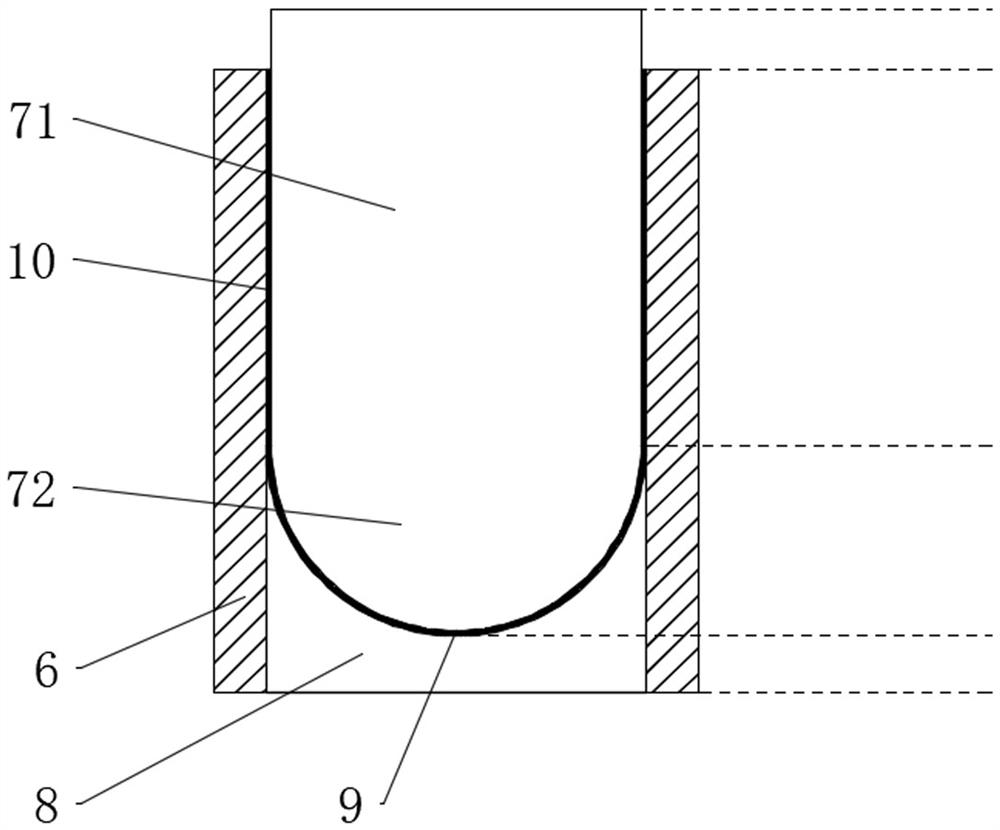

[0049] see figure 2 , a new preparation process of busbar 5 based on IGBT module. The IGBT module includes a liner 2, a substrate 1, a busbar 5, electrodes 4, semiconductor chips 3 and a casing, and a plurality of positioning cylinders 6 are fixedly connected to the liner 2. The positioning cylinder 6 innovatively replaces the traditional soldering pads. The traditional soldering pads can only achieve good electrical contact and do not have the positioning effect of the tooling. Moreover, the processing of the soldering pads is more difficult than the positioning cylinder 6. It is difficult for technicians. The technical requirement is higher, and the height of the positioning cylinder 6 in this embodiment is 5 mm, and a cylindrical hole is drilled in the positioning cylinder 6 to improve the space for accommodating electrical connections. The shape of the cylindrical hole can be set by the technician according to the actual situation, and It can be cylindrical or square, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com