Low Density FRP Radome and Its Production Process

A fiberglass radome and low-density technology, applied in the field of radome, can solve the problems of lack of stable physical, mechanical, electrical and chemical properties, unsatisfactory glass penetration effect, and inability to reduce the dielectric constant. Reduced temperature, good physical properties, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

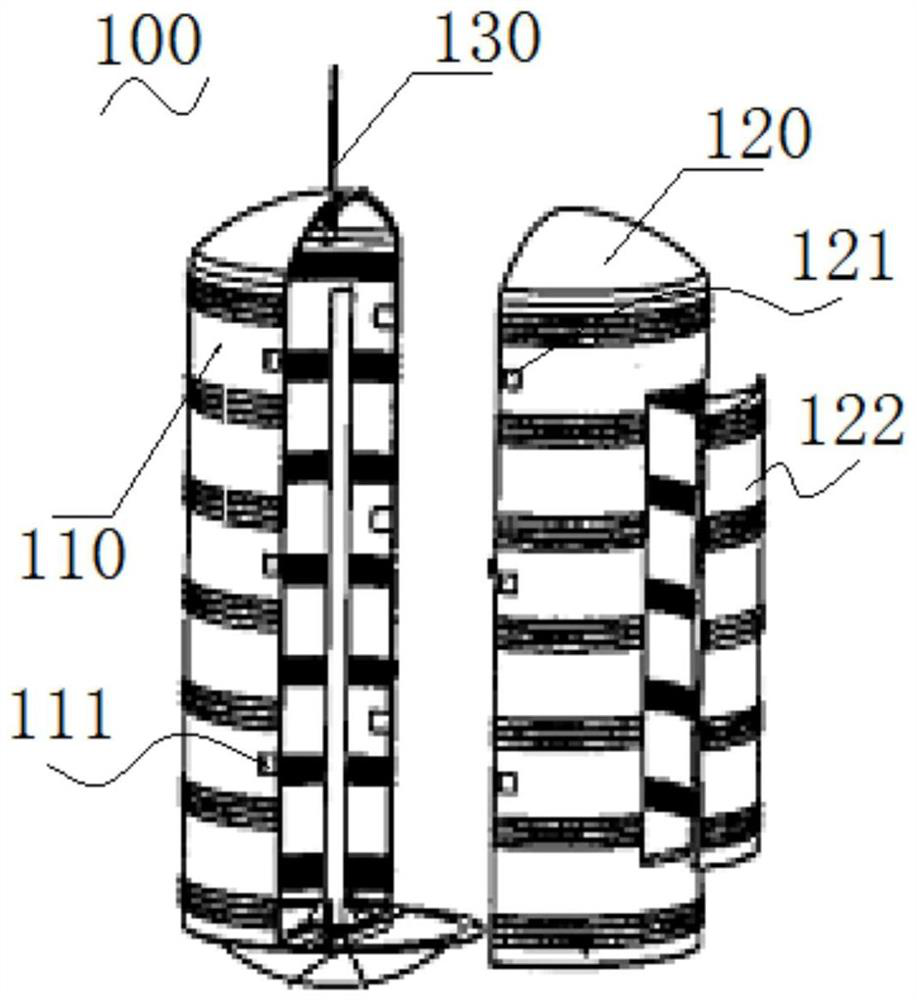

[0025] like figure 1 and figure 2 Shown is a schematic structural view and an exploded view of the radome of the present invention.

[0026] The low-density fiberglass radome 100 includes a first protective cover 110 and a second protective cover 120 that surround a hollow water tower shape, and the antenna pole is arranged in the hollow water tower-shaped cavity formed by the first protective cover 110 and the second protective cover 120. 130; the first protective cover 110 is provided with a first engaging member 111, and the second protective cover 120 is provided with a second engaging member 121 corresponding to the first engaging member 111 of the first protective cover 110, the first engaging The part 111 is connected with the second engaging part 121 so that the first protective cover 110 and the second protective cover 120 are detachably connected to form a hollow water tower-like structure. window 122.

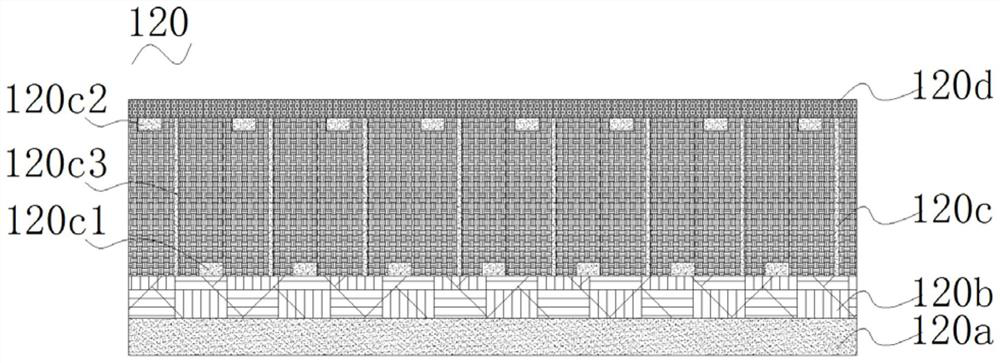

[0027] like image 3 Shown is a schematic cross-sectional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com