Slurry composition for chemical mechanical polishing

A chemical machinery and composition technology, applied in polishing compositions containing abrasives, other chemical processes, chemical instruments and methods, etc., can solve the problems of different grinding rates, and achieve the effects of increasing the grinding rate and easy adjustment of the selection ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

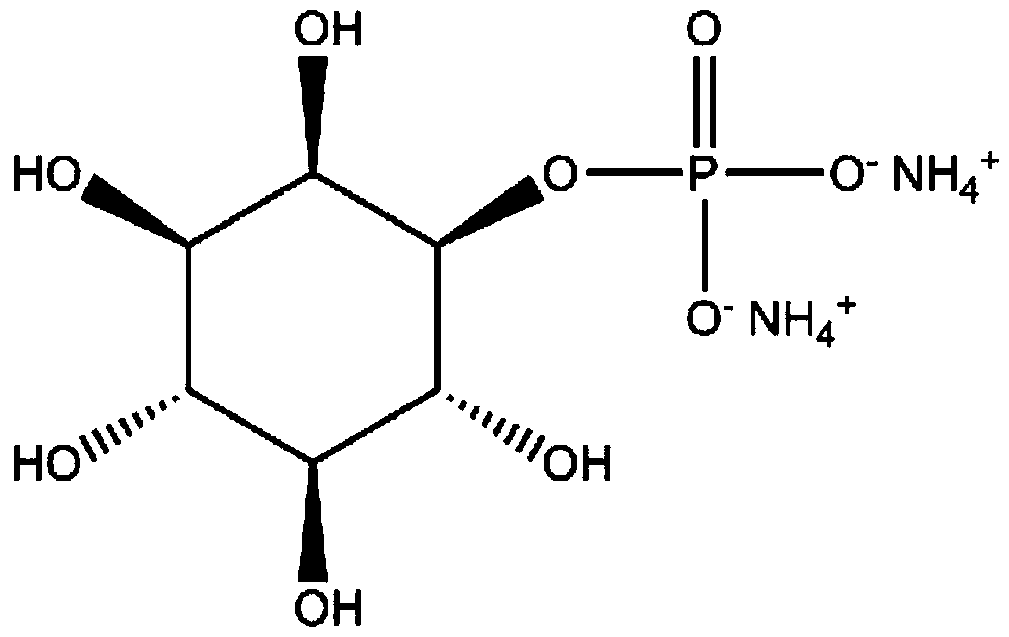

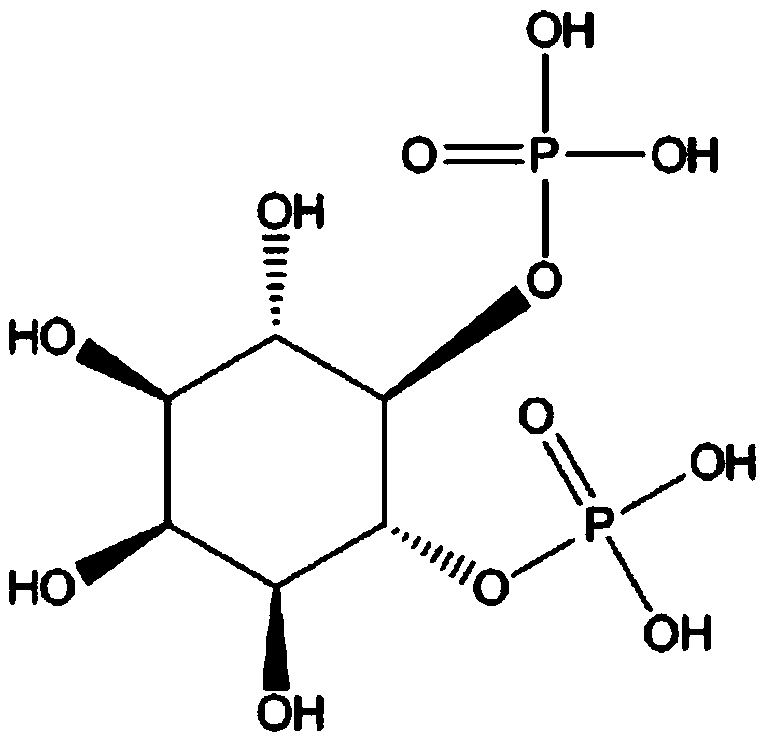

Image

Examples

Embodiment

[0112] About embodiment and comparative example, the grinding condition of the metal film of semiconductor substrate and the measuring method of grinding speed are as follows:

[0113] 1. Experimental wafer: tungsten (W) 8-inch blanket, silicon oxide film (PE-TEOS) 8-inch blanket, silicon nitride film (Si 3 N 4 )8 inch blanket

[0114] 2. Grinding equipment (Polisher): Mirra 3400 (Applied Materials)

[0115] 3. Grinding conditions: according to the method in Table 1

[0116] 【Table 1】

[0117]

[0118] 4. Grinding pad (Pad): IC-1000 (Rohm&Haas company)

[0119] 5. Thickness (grinding speed) measuring instrument (thickness unit: symbol: )

[0120] Tungsten film: CMT-2000 (4-point probe, Chang Min Tech.)

[0121] Silicon oxide film and silicon nitride film: Thermawave OP-2600 (KLA TENCOR)

[0122] [Formula 1]

[0123] Grinding speed = thickness before CMP – thickness after CMP

[0124] 6. Particle size (particle size) analysis instrument

[0125] ELS-Z (Otsuka E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com