A kind of food processing all-in-one machine

A food processing and integrated machine technology, applied in metal processing, food science, peeling of vegetables or fruits, etc., can solve the problems of poor coherence and low processing efficiency, and achieve improved device utilization, high processing efficiency, and crushing efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

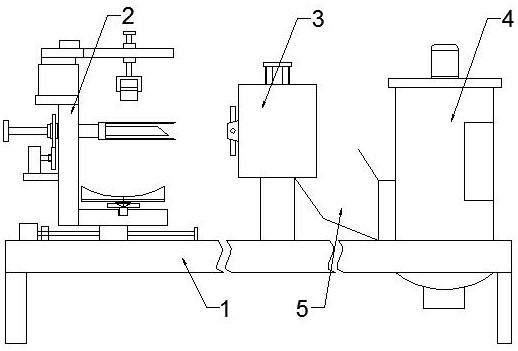

[0028] Example 1, such as figure 1 As shown, an integrated food processing machine includes a frame 1, on which a peeling mechanism 2, a cutting mechanism 3 and a crushing mechanism 4 are sequentially arranged, and the peeling mechanism 2 is used for peeling the fruits and vegetables to be processed , the cutting mechanism 3 is used to cut the fruits and vegetables to be processed (fruits and vegetables that have been peeled) into pieces or strips; the crushing mechanism 4 is used to crush the divided fruits and vegetables to make smaller fruit particles and pulp Production. The peeling mechanism 2 corresponds to the cutting mechanism 3, that is, the fruits and vegetables that have been peeled at the peeling mechanism can directly enter the cutting mechanism for the next step of processing. A conveying pipeline 5 is arranged between the cutting mechanism 3 and the crushing mechanism 4, and the fruits and vegetables cut by the cutting mechanism fall into the conveying pipeline...

Embodiment 2

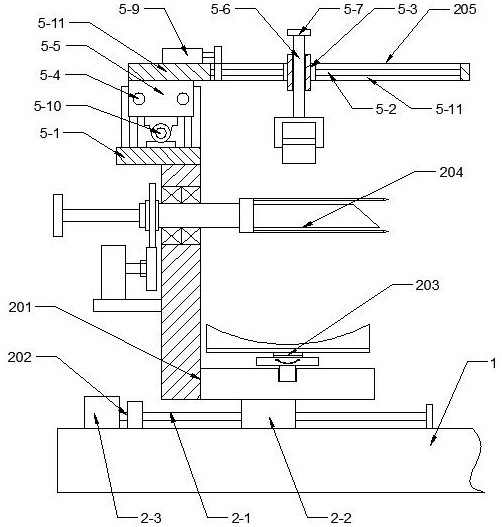

[0029] Example 2, such as figure 1 with 2 As shown, a food processing integrated machine, the telescopic mechanism 202 includes a horizontal lead screw 2-1 arranged on the frame 1, the two ends of the horizontal lead screw are connected to the frame through bearings, and the horizontal lead screw 2-1 A threaded seat 2-2 is provided on the top, and the threaded seat is threadedly connected with the horizontal lead screw, and the horizontal lead screw is rotated, and the threaded seat moves along the horizontal lead screw. The upper part of the threaded seat 2-2 is fixedly connected with the plate seat 201, and the threaded seat drives the plate seat to move during the movement, and the horizontal lead screw 2-1 and the first motor 2-3 arranged on the frame 1 pass through a coupling or a gear The auxiliary phases are connected. During the processing, the first motor rotates to drive the horizontal screw to rotate, and then the threaded seat drives the plate seat to move, so as ...

Embodiment 3

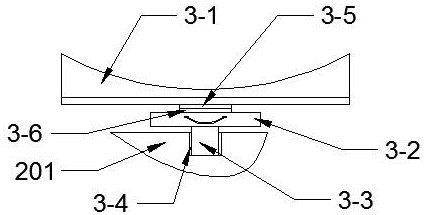

[0034] Example 3, such as Figure 5 As shown, a food processing integrated machine, the cutting mechanism 3 includes a support frame 301, the support frame is connected to the frame, and the support frame 301 is provided with a cutting bin 302, which is a box with front and rear openings, The lower part of the cutting chamber 302 is provided with a cutting board 303, one end of the cutting board 303 is hinged with the cutting chamber 302, and the other end is connected with the cutting chamber 302 through the first cylinder 303, and the cutting board is lifted by the expansion and contraction of the first cylinder Or not, in normal state, the chopping board is in a horizontal state. After the cutting is completed, the first cylinder stretches out, lifts up the chopping board, pours blocky fruits and vegetables into the slideway, and enters the next process through the slideway. The top of the slitting bin 302 is provided with a vertically arranged second cylinder 304, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com