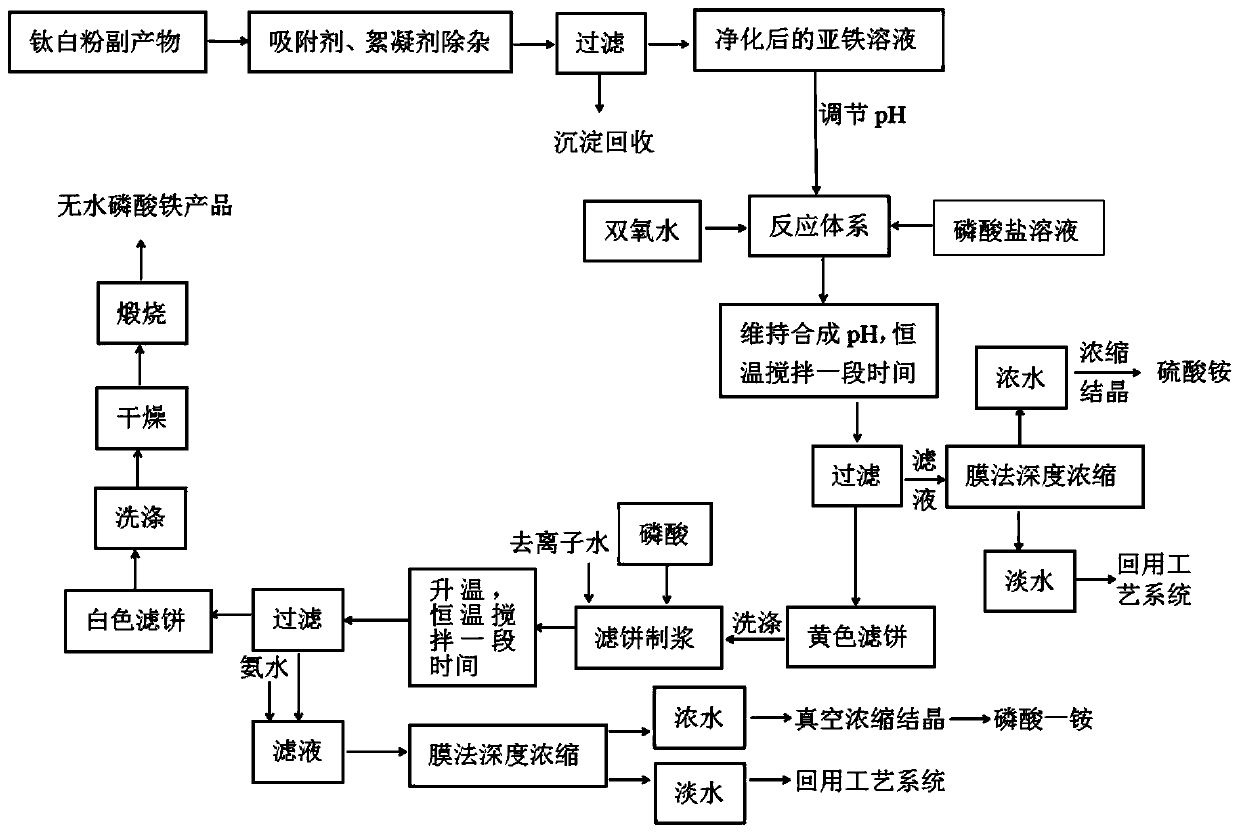

Synthesis process of battery-grade iron phosphate

A synthesis process, the technology of iron phosphate, applied in the direction of phosphorus compounds, battery electrodes, circuits, etc., can solve the problems of poor product stability and consistency, low product purity, high production cost, and achieve stability and consistency guarantee, impurities Less, less product differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

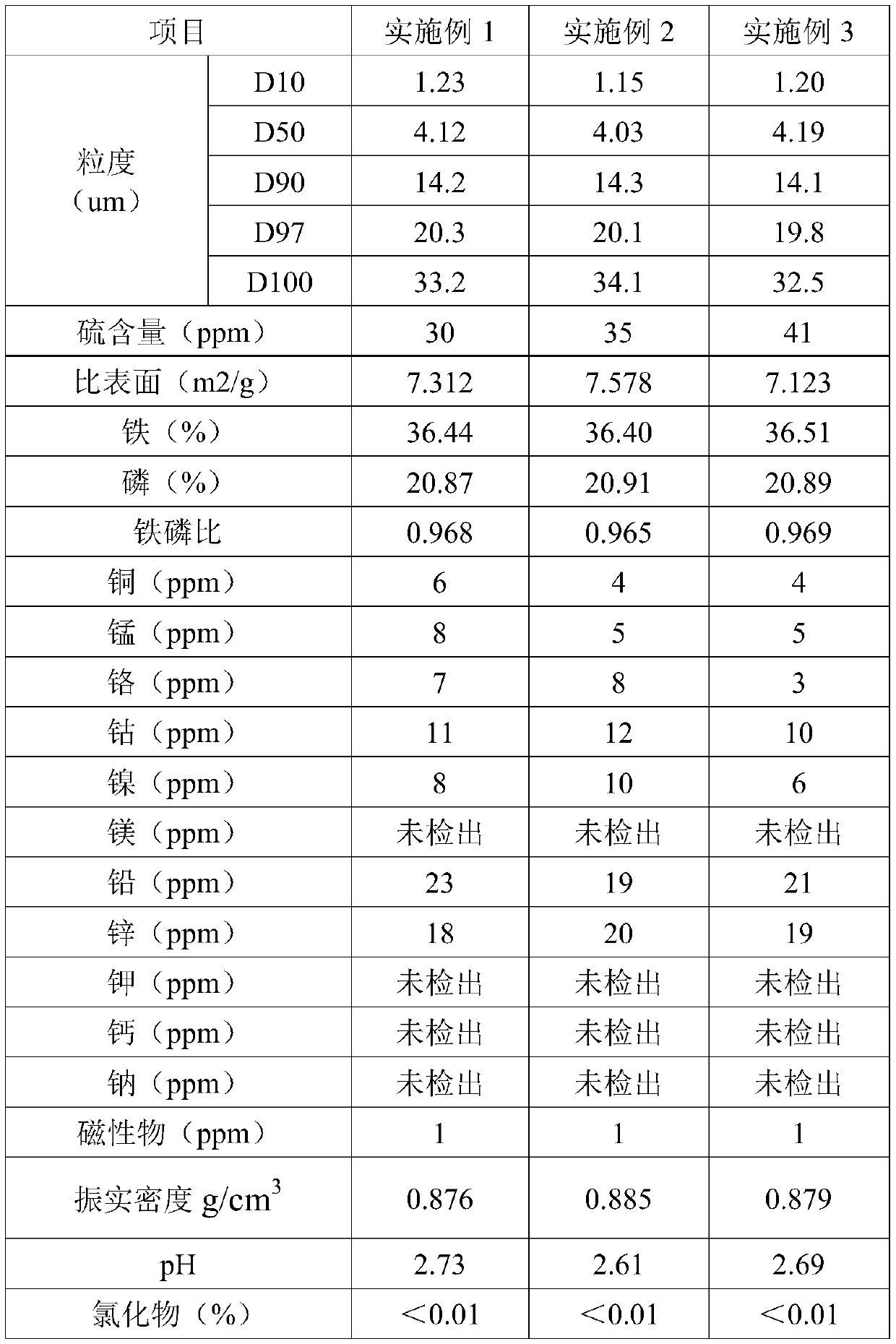

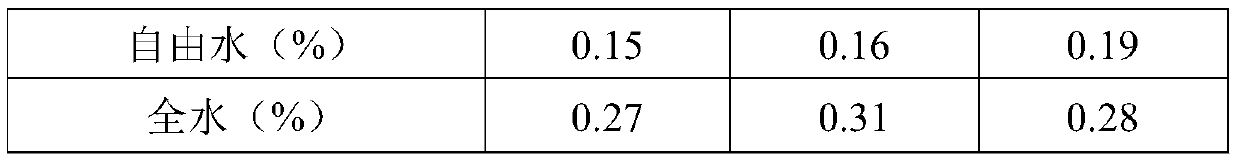

Examples

Embodiment 1

[0027] Dissolve 500g of titanium dioxide by-product ferrous sulfate, configure it into a ferrous sulfate solution with an iron concentration of 0.5mol / L, set the pH at 1-1.2 (adjustable with phosphoric acid or sulfuric acid), then add 20g of adsorbent to control the stirring speed 100r / min, stir at room temperature for 30min, add 10g flocculant, stir for 5min, stop stirring and let the material rest for 10min. Then filter to remove impurities until the solution is completely clear, and the obtained ferrous solution is ready for use.

[0028] Take 500 mL of the above purified and purified ferrous sulfate solution, add concentrated sulfuric acid (or phosphoric acid) to adjust the pH of the solution to 0.5. With the ferrous sulfate solution after above-mentioned acidification, phosphorus content is the phosphate solution 250ml of 1mol / L, 30% hydrogen peroxide 15.45ml, three are added dropwise in the reaction system simultaneously, and system pH is stabilized at 0.5 (using ammonia...

Embodiment 2

[0030] Dissolve 500g of titanium dioxide by-product ferrous sulfate, configure it into a ferrous sulfate solution with an iron concentration of 0.75mol / L, set the pH at 1.2-1.8, then add 25g of adsorbent, control the stirring speed at 150r / min, and stir at room temperature for 30min , add 15g flocculant, stir for 5min, stop stirring and let the material rest for 10min. The material is filtered for many times to remove impurities until the solution is completely clear, and the obtained ferrous solution is ready for use.

[0031] Take 500 mL of the above purified and purified ferrous sulfate solution, add concentrated sulfuric acid or ammonia water to adjust the pH of the solution to 1.25. With acidified ferrous sulfate solution, phosphorus content is 288ml of phosphate solution of 1.5mol / L, 34.77ml of 30% hydrogen peroxide, the three are added dropwise in the reaction system at the same time, and the pH of the system is stabilized at 1.5 (using ammonia or phosphoric acid Adjus...

Embodiment 3

[0033] Dissolve 500g of titanium dioxide by-product ferrous sulfate, configure it into a ferrous sulfate solution with an iron concentration of 1mol / L, set the pH at 1.8-2.5, then add 30g of adsorbent, control the stirring speed at 200r / min, and stir at room temperature for 30min. Add 20g flocculant, stir for 5min, stop stirring and let the material rest for 10min. The material is filtered for many times to remove impurities until the solution is completely clear, and the obtained ferrous solution is ready for use.

[0034]Take 500 mL of the above-mentioned purified and purified ferrous sulfate solution, add concentrated sulfuric acid or ammonia water to adjust the pH=2 of the solution. With acidified ferrous sulfate solution, phosphorus content is 325ml of phosphate solution of 2mol / L, 61.82ml of 30% hydrogen peroxide, the three are added dropwise in the reaction system at the same time, and the pH of the system is stabilized at 2.5 (adjusted by ammonia or phosphoric acid) )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com