Water-based epoxy anticorrosive primer for container

A water-based epoxy and anti-corrosion primer technology, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc. The effect of improving dryness and improving anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

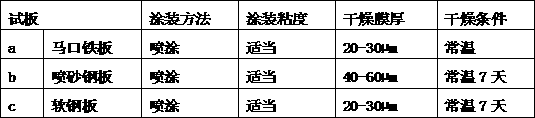

Examples

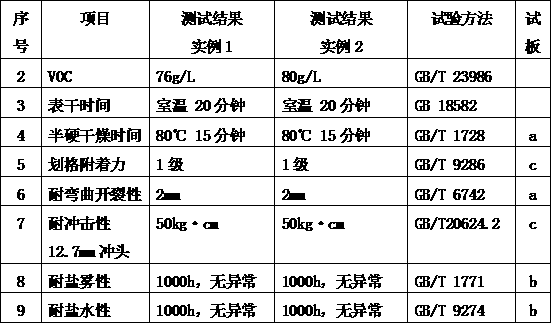

Embodiment 1

[0040] A waterborne epoxy anti-corrosion primer for containers, consisting of A and B components.

[0041] Among them, component A includes: epoxy resin emulsion 420kg, water-based functional emulsion 60kg, dispersant 10kg, surfactant 2kg, defoamer 2kg, iron oxide pigment 100kg, antirust pigment 80kg, functional filler 40kg, talcum powder 140kg, 20kg coalescent, 3kg thickener, 123kg purified water. Component B includes: modified amine curing agent 110kg, anti-flash rust agent 4kg, purified water 86kg.

[0042] Among them, the epoxy resin emulsion in component A is EPIKOTE 6520-WH-53A from Momentive, the water-based functional emulsion is LINTEC ER-5100 from Nanlinte New Material Technology, and the dispersant is VXW6208-60 from Allnex , the surfactant is TEGO® Twin 4100 from Evonik, the defoamer is BYK-024 from BYK, the iron oxide pigment is iron oxide red H130 from Hunan Sanhuan, and the antirust pigment is Nubirox 106 from Nubirox. The water-based aluminum powder slurry us...

Embodiment 2

[0052] A waterborne epoxy anti-corrosion primer for containers, consisting of A and B components.

[0053] Among them, component A includes: epoxy resin emulsion 350kg, water-based functional emulsion 50kg, dispersant 8kg, surfactant 1.5kg, defoamer 2kg, iron oxide pigment 82kg, antirust pigment 65kg, functional filler 35kg, talc Powder 118kg, film-forming aid 17kg, thickener 2.5kg, purified water 102.5kg. Component B includes: modified amine curing agent 55kg, anti-flash rust agent 2kg, purified water 43kg.

[0054] Among them, the epoxy resin emulsion in component A is EPIKOTE 6520-WH-53A from Momentive, the water-based functional emulsion is LINTEC ER-5100 from Nanlinte New Material Technology, and the dispersant is VXW6208-60 from Allnex , the surfactant is TEGO® Twin 4100 from Evonik, the defoamer is BYK-024 from BYK, the iron oxide pigment is iron oxide red H130 from Hunan Sanhuan, and the antirust pigment is Nubirox 106 from Nubirox. The water-based aluminum powder sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com