Swap Station Battery Replacement Cleaning System

A technology for battery replacement and cleaning system, applied in charging stations, cleaning methods and appliances, cleaning methods using tools, etc., can solve problems such as hidden dangers of battery safety, flying dust, charging failures, etc., to improve space utilization and battery replacement. Work efficiency, prevent rainwater from dripping on the power battery electrical connector, and improve the effect of charging safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

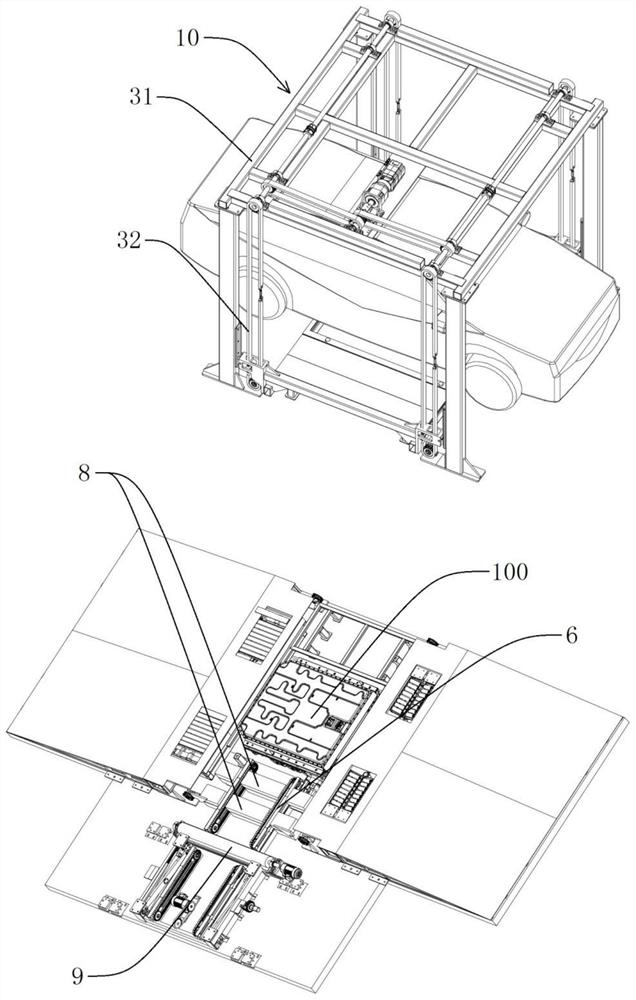

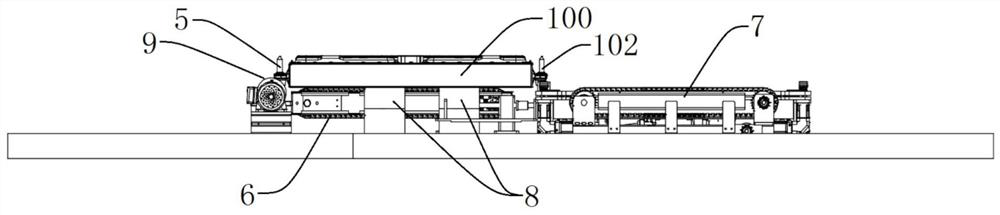

[0036] Such as figure 1 As shown, the present embodiment is provided with a lifting device 10 and a battery delivery line 6 .

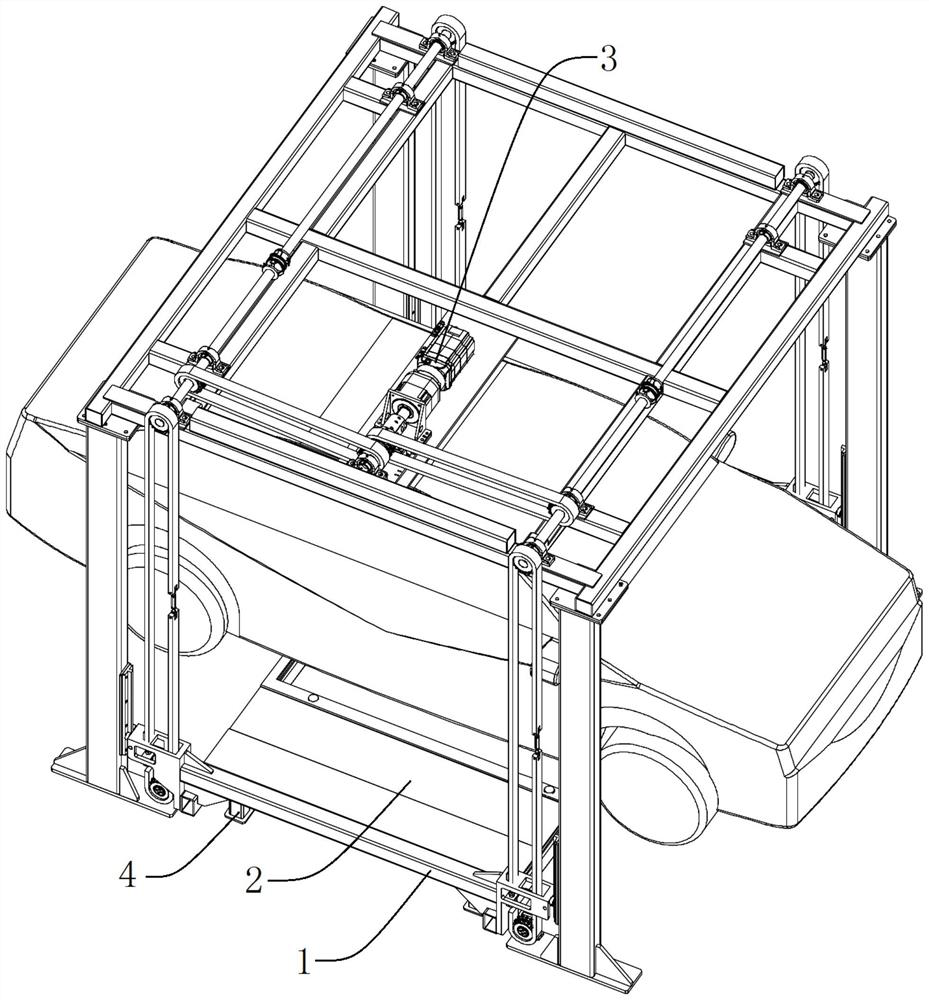

[0037] Such as image 3 and Figure 4 As shown, the car lifting device 10 includes a load-bearing frame 1, a floating platform 2, a lifting mechanism 3 and a floating platform support column 4; the load-bearing frame 1 is driven up and down by the lifting mechanism 3, and the load-bearing frame 1 is provided with an automobile chassis positioning column 13; The floating platform 2 is sleeved on the positioning column 13 of the automobile chassis, falls with the rise of the load-bearing frame, and contacts with the main body of the load-bearing frame; the support column 4 of the floating platform supports the floating platform when the load-bearing frame 1 is in an unraised initial position 2. Keep the floating platform 2 basically level with the load-bearing frame 1 .

[0038] Preferably, the load-bearing frame 1 includes an outer frame 11 and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com