Device for fertilizing organic waste and using method

A technology of organic waste and fertilizer, which is applied in the field of organic waste treatment, can solve the problems that the maintenance cost fails to solve the resource utilization rate of organic waste, and affects the resource utilization rate of organic waste, so as to achieve harmless and resource utilization, easy internal ventilation, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

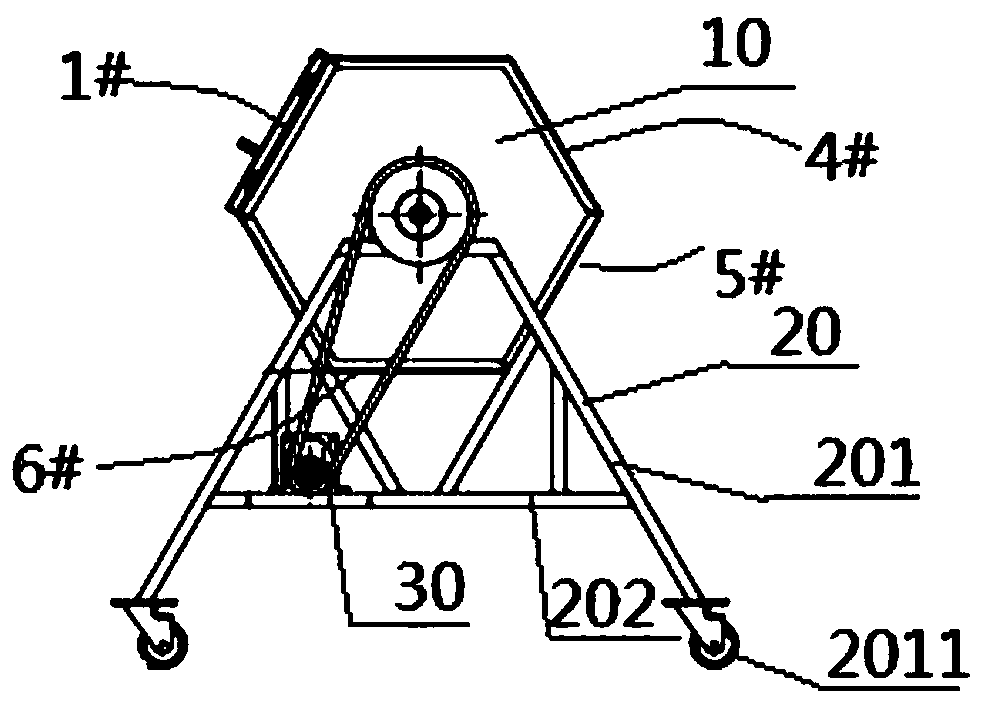

[0050] To achieve the above purpose, if figure 1 As shown, according to an embodiment of the present invention, this patent adopts the following technical solution: an energy-saving organic waste fertilization device, which mainly includes a drum 10, a drum support 20 and an electric drive unit 30, wherein

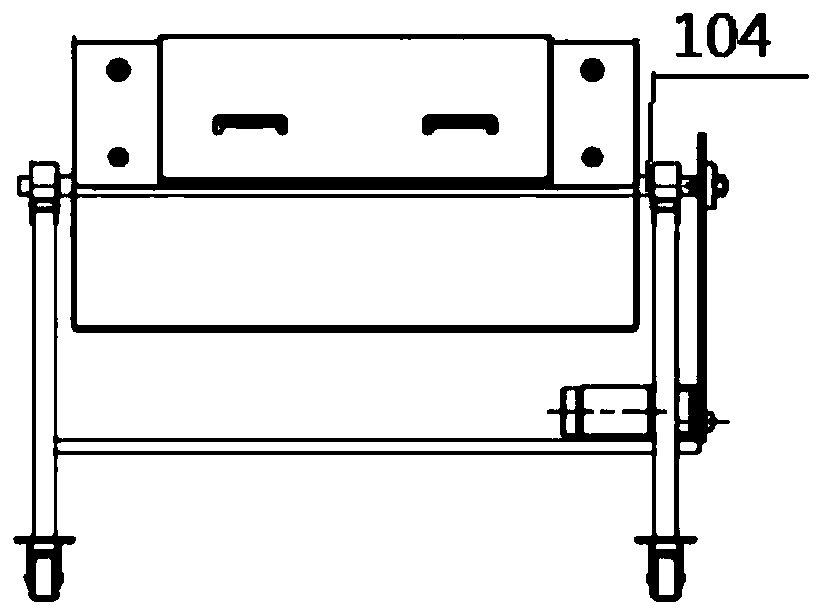

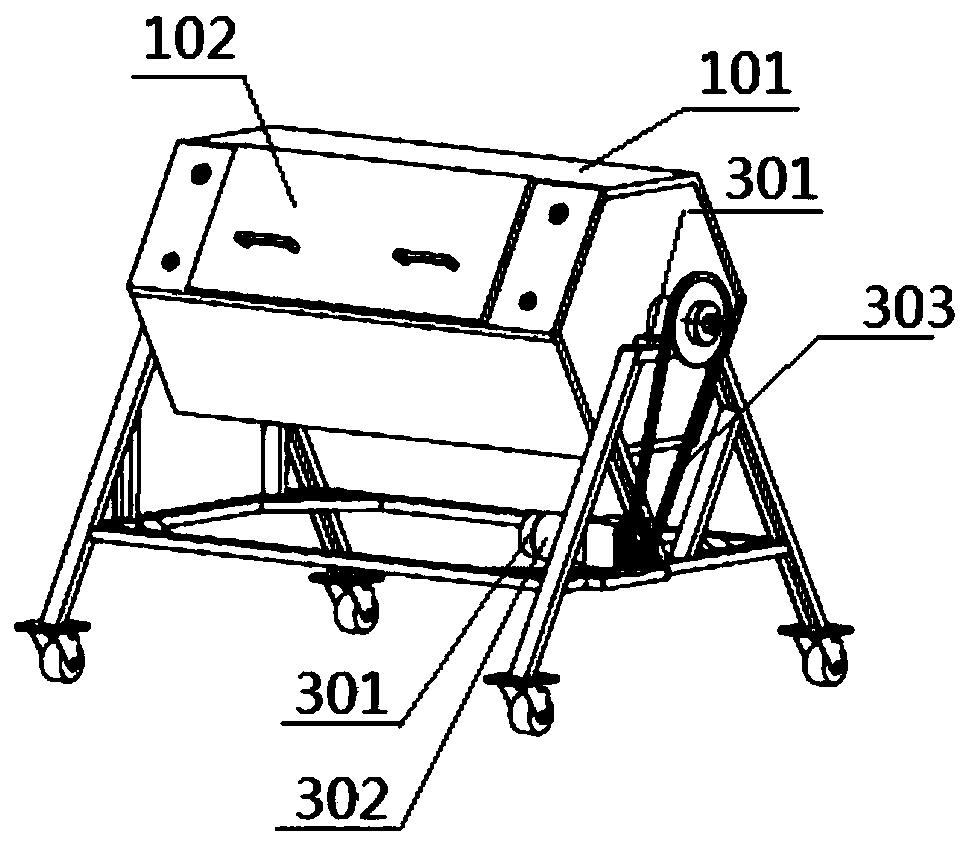

[0051] Such as image 3 As shown, the outer wall of the drum 10 is a polyhedron structure, several surfaces of the peripheral surface of the outer wall can be provided with solar panels 101, and the remaining side is provided with an openable cover 102, and a heater 103 is provided inside the drum. (Such as Figure 4 shown);

[0052] Such as figure 1 As shown, the roller bracket 20 is arranged below the roller 10, and the roller 10 is rotatably arranged on the roller bracket 20;

[0053] The electric drive unit 30 mainly includes a battery 301 , a motor 302 and a transmission part 303 , and the battery is respectively connected to the solar panel, the motor and the hea...

Embodiment 1

[0093] Experiment site: Greenhouse Base of Beijing Academy of Agriculture and Forestry Sciences

[0094] Experiment time: December 3-18, 2018.

[0095] Experimental materials: Flammulina velutipes mushroom residue (moisture content 40-50%), small rapeseed (moisture content 85-90%).

[0096] experimental method:

[0097] Two treatment groups were set up in the drum fermentation experiment:

[0098] Solar heating group: place the composting drum outdoors, put 30-35 kg of mushroom dregs and 20-25 kg of small rape tails into the drum fermentation tank, turn on the solar heating and heat preservation function after the materials are evenly rotated, and wait for the materials to rise above 25°C. Turn off the heating function.

[0099] Control group without heating: the composting drum was placed outdoors, 30-35 kg of mushroom residues and 20-25 kg of small rape tails were put into the drum fermentation tank, and the solar heating and heat preservation function was not turned on. ...

Embodiment 2

[0113] Experiment site: Greenhouse Base of Beijing Academy of Agriculture and Forestry Sciences

[0114] Experiment time: January 14-28, 2019.

[0115] Experimental materials: Flammulina velutipes mushroom residue (moisture content 40-50%), small rapeseed (moisture content 85-90%).

[0116] experimental method:

[0117] Two treatment groups were set up in the drum fermentation experiment:

[0118] Solar heating group: place the composting drum outdoors, put 30-35 kg of mushroom dregs and 20-25 kg of small rape tails into the drum fermentation tank, turn on the solar heating and heat preservation function after the materials are evenly rotated, and wait for the materials to rise above 25°C. Turn off the heating function.

[0119] Control group without heating: the composting drum was placed outdoors, 30-35 kg of mushroom residues and 20-25 kg of small rape tails were put into the drum fermentation tank, and the solar heating and heat preservation function was not turned on. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com