Horizontal-type solid-state fermentation tank with controllable temperature and humidity

A solid-state fermenter, temperature and humidity technology, applied in specific-purpose bioreactor/fermenter, solid-phase fermentation bioreactor, bioreactor/fermenter combination, etc., can solve the problem of cumbersome use, single humidification or dehumidification, Single temperature control and other issues to achieve the effect of simple structure, convenient use and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

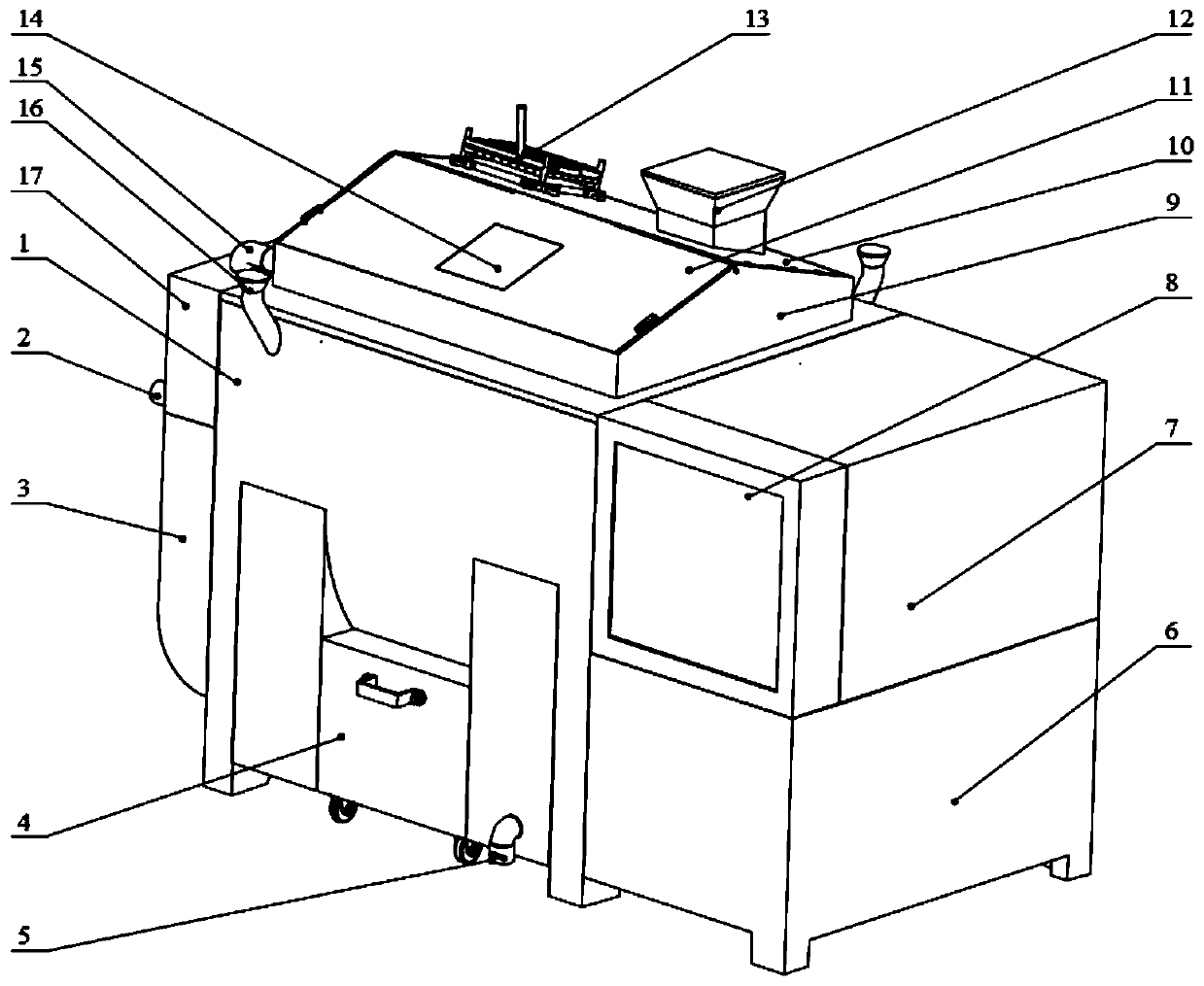

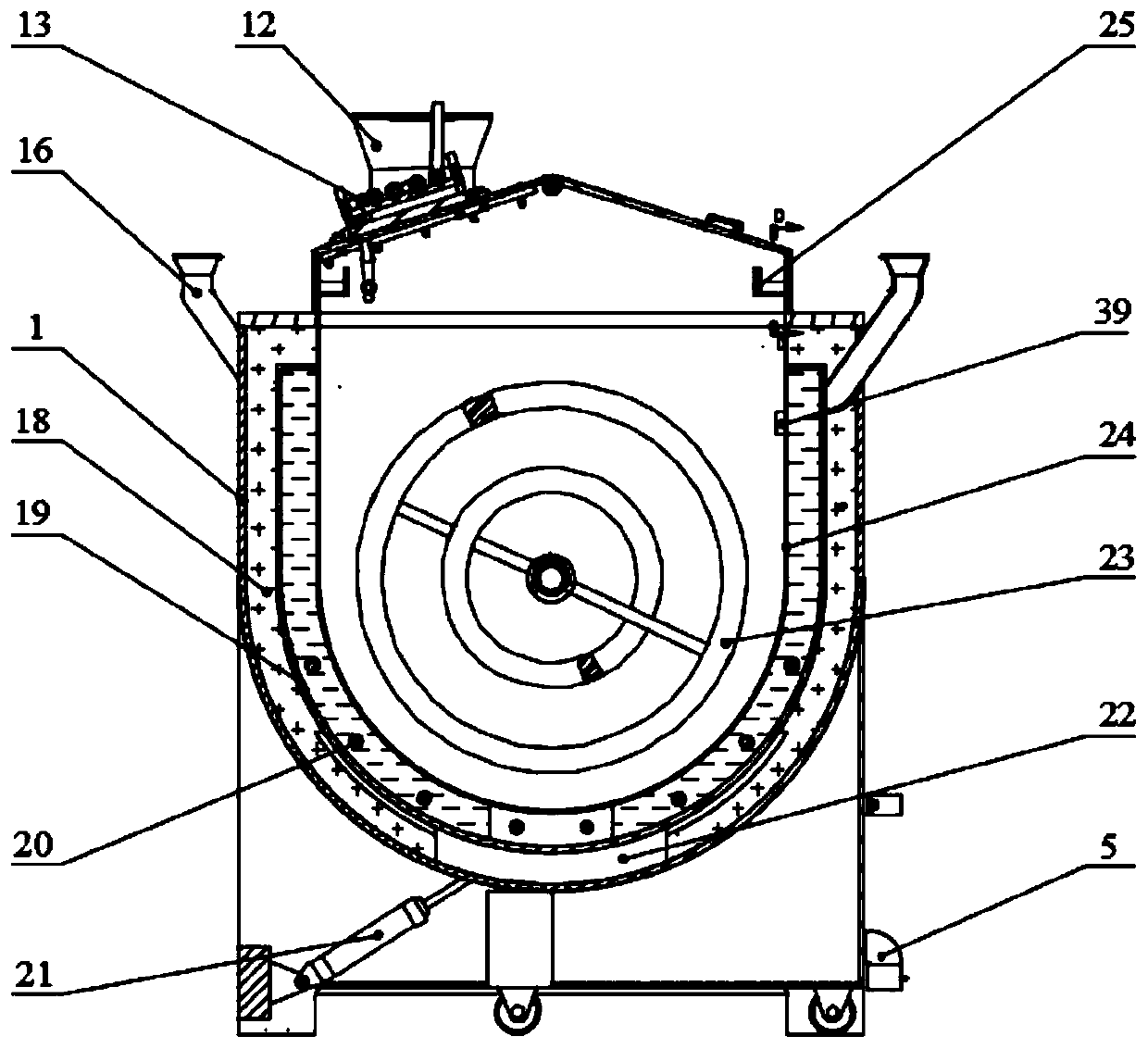

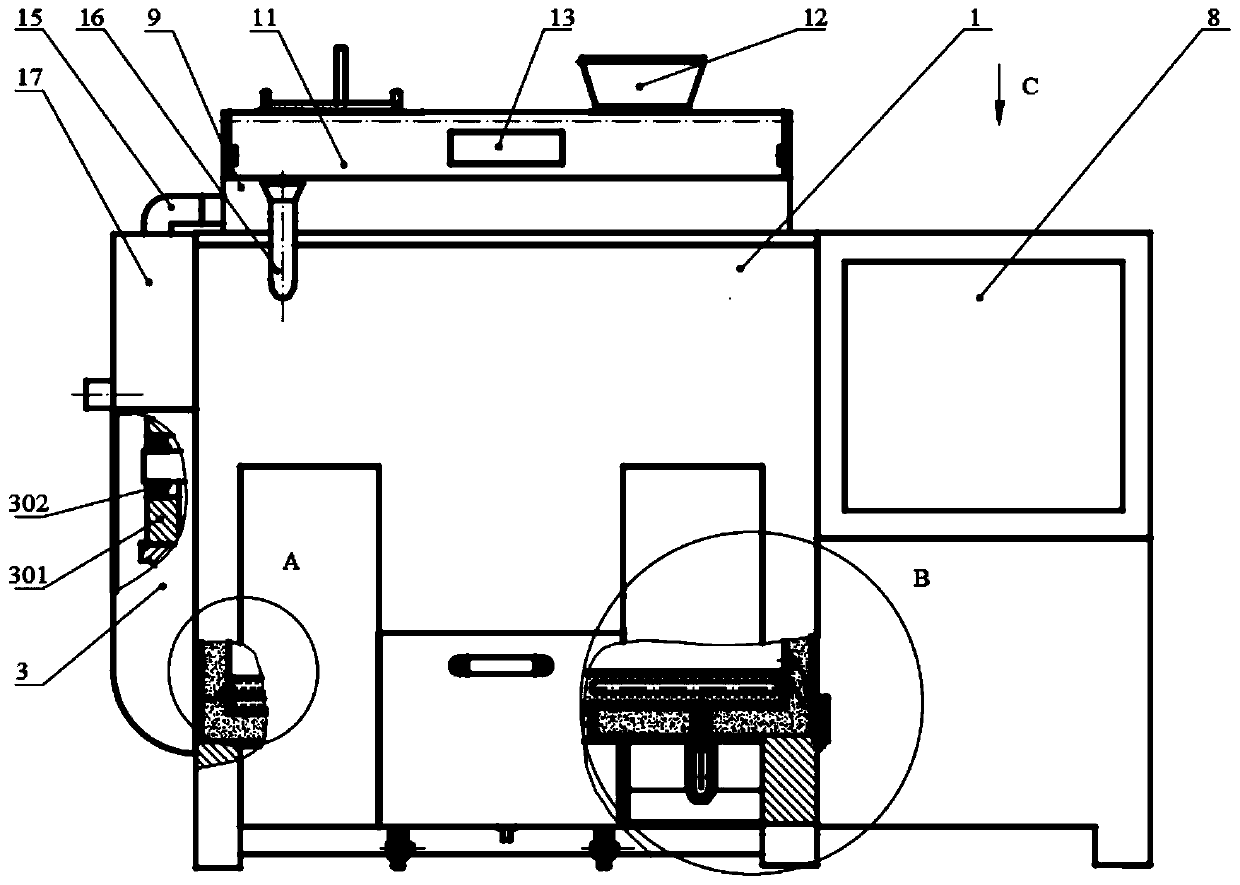

[0025] see figure 1 , figure 2 , image 3 A horizontal solid-state fermenter with controllable temperature and humidity includes a fermenter body, a stirring system, a humidity control system, a heating system, a power system, and other components such as a feeding and unloading device. Wherein, the fermenter body includes an outer shell 1 , an insulating layer 18 , an oil chamber 19 , an inner shell 24 and an upper cover shell 9 . The inner shell 24 is U-shaped, and the entire U-shaped outer surface of the inner shell 24 is wrapped by the oil chamber 19, and heat transfer oil can be stored in the oil chamber 19. There is a thermal insulation layer 18 between the oil cavity 19 and the inner wall of the casing 1, and the thermal insulation layer 18 is a thermal insulation material, which can reduce the loss of inter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap