Water-rich sand gravel stratum connecting tunnel underground excavation crossing urban main road construction method

A construction method and technology of sand and pebble, applied in drainage, tunnel, tunnel lining and other directions, can solve the problems of poor formation self-stability and high excavation risk, and achieve the effect of fast construction schedule, effective formation subsidence control, and reasonable measures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Subway station construction in the central area of a northern city. The subway station is located in the bustling area of the city, and it needs to pass through the main road of the city when it is built. There is a crossing section at the west end of this interval, with many types of sections and frequent transitions; moreover, there are many sudden changes, and the excavation profiles of the sections are greatly different. The adjacent standard section is only 2.3m. The main structure of the interval is mainly located in the medium-coarse sand layer, silt-fine sand layer and pebble-round gravel layer. The soil is disturbed many times during the initial excavation, which will directly affect the settlement of the road and the upper pipeline.

[0029] Therefore, it is finally determined through various schemes that the construction method of crossing the line section of the water-rich sand and pebble stratum of the present invention is excavated and crossed the mai...

Embodiment 2

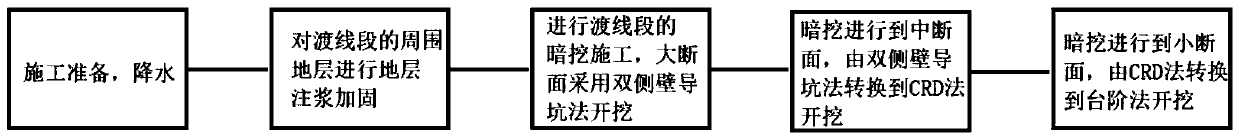

[0042] The invention relates to a construction method for submerged crossing sections of water-rich sand and pebble strata to cross urban arterial roads. Such as figure 1 As shown, the method includes the following steps:

[0043] a. Construction preparation, and dewatering construction is required before construction, and the water level is lowered to 0.5-1m below the structural floor. And timely carry out open drainage treatment for the stagnant water between layers to ensure construction safety;

[0044] b. Carry out stratum grouting reinforcement to the strata around the crossing section. After the stratum grouting reinforcement is completed, erect temporary steel supports at the crossing section, and then build an arched pipe shed and perform grouting reinforcement on the pipe shed;

[0045] c. Carry out underground excavation construction for the line crossing section, and use the double-side-wall pilot pit method for excavation of the large section: the excavation fir...

Embodiment 3

[0067] The invention relates to a construction method for submerged crossing sections of water-rich sand and pebble strata to cross urban arterial roads. Such as figure 1 As shown, the method includes the following steps:

[0068] a. Construction preparation, and dewatering construction is required before construction, and the water level is lowered to 0.5-1m below the structural floor. And timely carry out open drainage treatment for the stagnant water between layers to ensure construction safety;

[0069] b. Carry out stratum grouting reinforcement to the strata around the crossing section. After the stratum grouting reinforcement is completed, erect temporary steel supports at the crossing section, and then build an arched pipe shed and perform grouting reinforcement on the pipe shed;

[0070] c. Carry out underground excavation construction for the line crossing section, and use the double-side-wall pilot pit method for excavation of the large section: the excavation fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section height | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com