Flue gas desulfurization tower and flue gas desulfurization and wastewater treatment process

A desulfurization tower and flue gas technology, applied in the direction of gaseous effluent wastewater treatment, gas treatment, water/sewage treatment, etc., can solve problems such as strong visual impact, white smoke, ground dust rain, etc., to reduce energy consumption and dust removal efficiency High, save the effect of flushing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

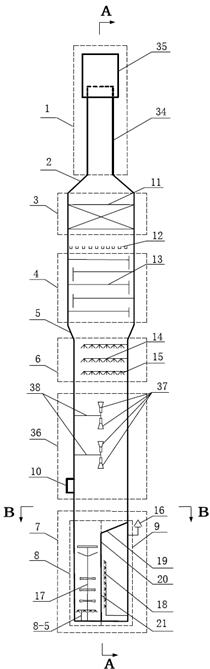

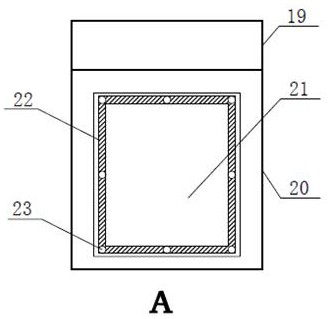

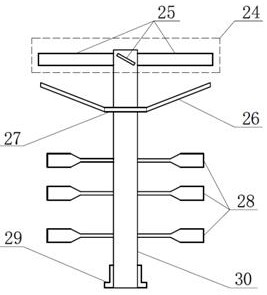

[0075] A flue gas desulfurization tower, from top to bottom is a flue gas discharge area 1, a demisting area 3, a tower area 4, a spray area 6, a rapid cooling cooling area 36 and a waste water treatment area 7, the flue gas discharge area 1 and the The defogging zone 3 is connected by a cone-shaped variable diameter 2, the tower plate zone 4 is below the defogging zone 3, the tower plate zone 4 and the spray zone 6 are connected by an inverted cone-shaped variable diameter 5, and the quenching cooling zone is below the spray zone 6 36. Below the rapid cooling zone 36 is the waste water treatment zone 7.

[0076] The chimney 34 structure in the conventional flue gas wet desulfurization process is set in the flue gas discharge area 1. The bottom of the chimney 34 is connected with the tower body of the demisting area 3 through a cone-shaped diameter 2, and an outer sleeve 35 is set on the top of the chimney 34. The sleeve 35 is a cylindrical structure with upper and lower openi...

Embodiment 2

[0087] The boiler flue gas temperature of an enterprise is 152°C, where SO 2 The concentration is 1000mg / Nm 3 , Dust concentration is 260mg / Nm 3 , using the flue gas desulfurization tower of the present invention, the diameter of the chimney 27 is 4m, the diameter of the outer sleeve is 5m, the diameter of the tower body in the demisting area 3 and the tray area 4 is 10m, the spraying area 6, the quenching cooling area 36 The diameter of the 7th tower body in the waste water treatment area is 8m, and the clean water flow rate in the rapid cooling cooling area is 80 m 3 / h. SO in exhaust flue gas 2 The content is measured by German Testo flue gas analyzer (model Testo-350). The dust content is measured according to GB / T 16157-1996 "Sampling Method for Particulate Matter and Gaseous Pollutants in Exhaust from Stationary Pollution Sources". The gas is filtered, dissolved in water, and the salt content is measured and calculated according to HJ / T51-1999 "Gravimetric Method for...

Embodiment 3

[0089] As a comparison, the flue gas desulfurization tower is not equipped with an outer sleeve 28, and the rest is the same as that of Example 2, and the length of the "white smoke" at the chimney mouth is 80m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com