MBR (membrane bioreactor) membrane aerator, MBR membrane aeration device and MBR membrane sewage treatment equipment

A technology of membrane aeration and air flow, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic process treatment, etc., can solve problems such as aeration pipe blockage, and achieve low loss and small pressure loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

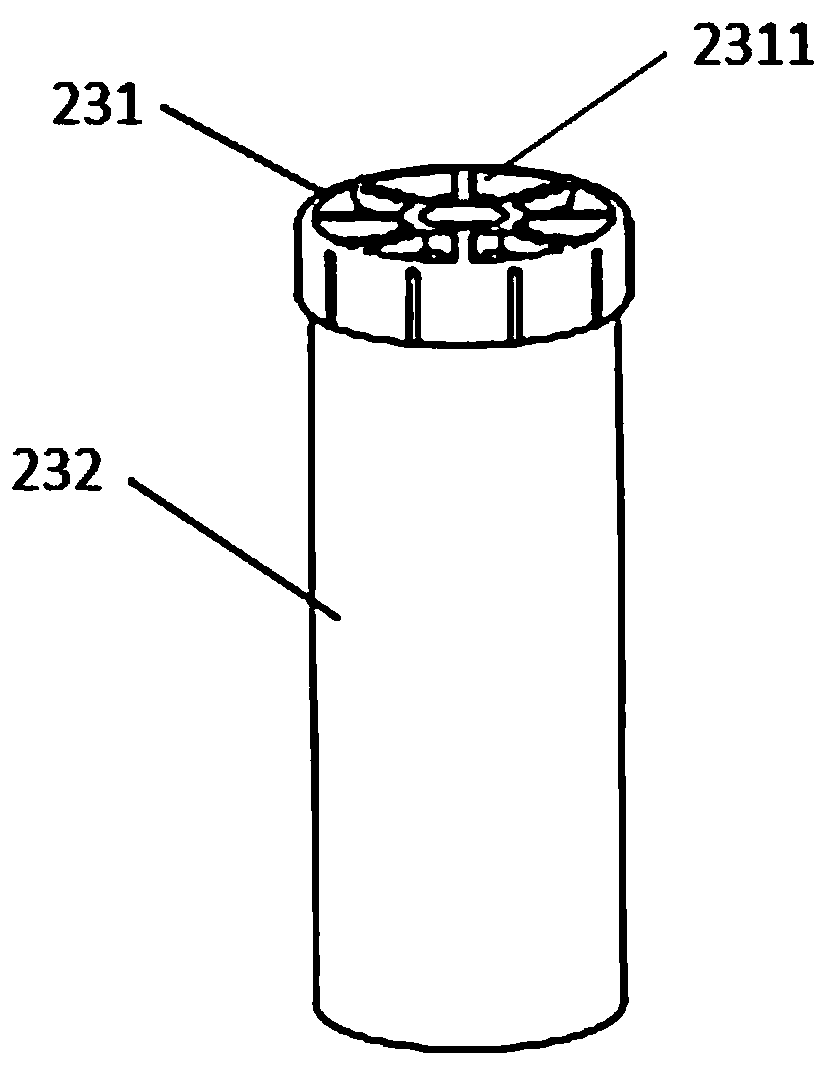

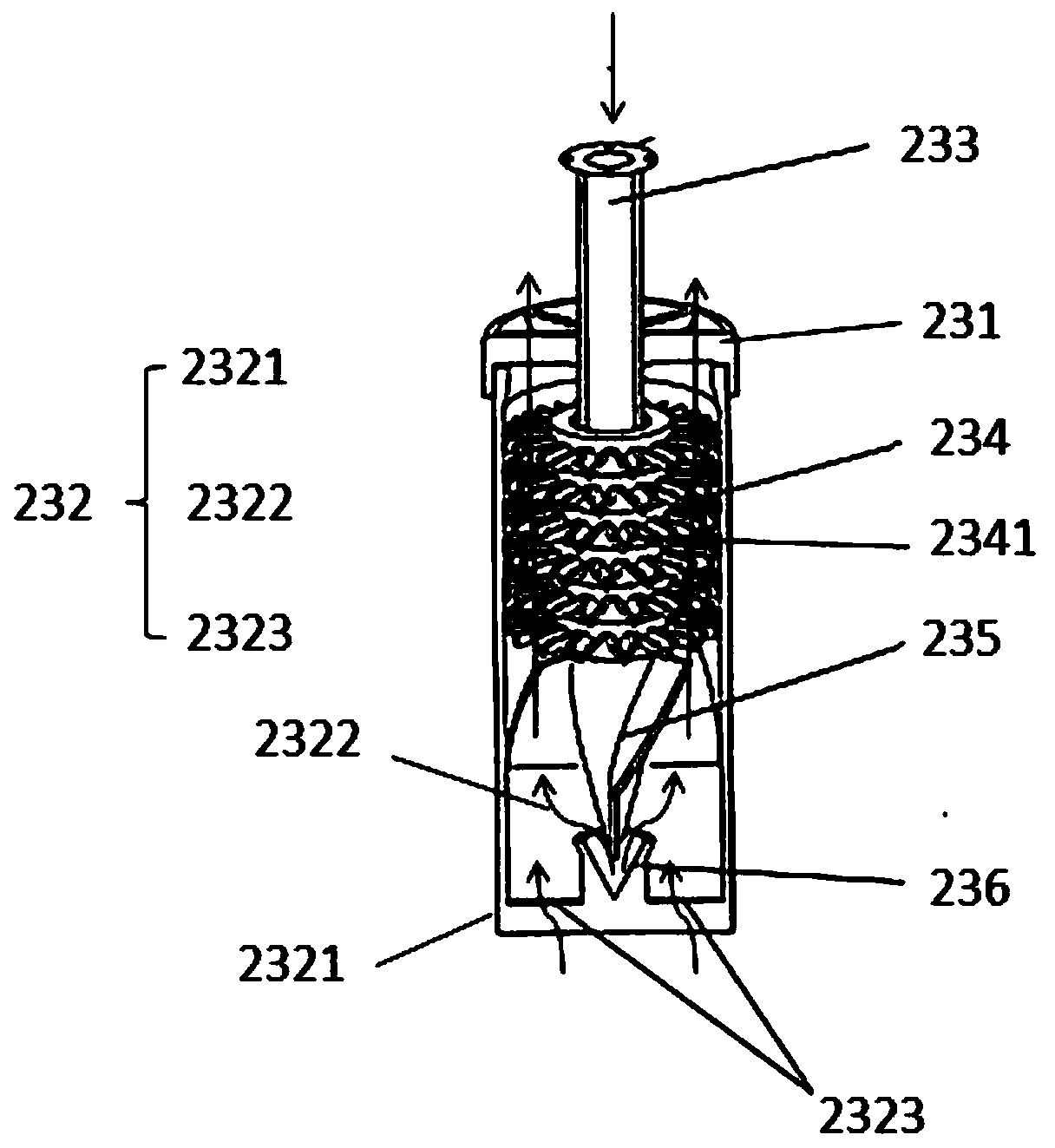

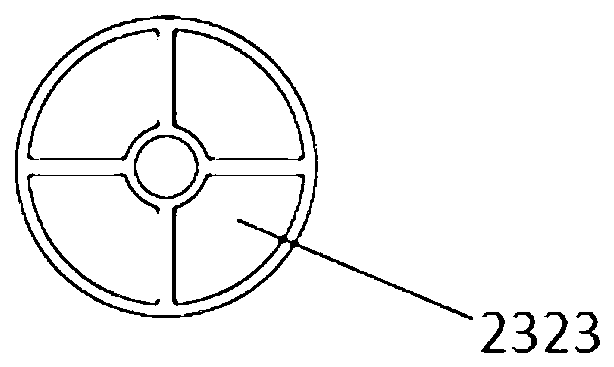

[0035] see Figure 1 to Figure 3 as shown, figure 1 It is a schematic diagram of the appearance of the MBR membrane aerator, figure 2 It is the internal structure diagram of the MBR membrane aerator, image 3 It is a bottom view of the MBR membrane aerator, and the present invention provides an MBR membrane aerator, which includes a top cover 231, the upper end of the top cover 231 has a through mixed liquid outlet 2311; a body 232, including an outer shell 2321 with an open top and the mixing cavity 2322, the mixing cavity 2322 is located in the outer shell 2321, the top cover 231 is buckled on the upper end of the outer shell 2321, and the bottom end of the body 232 is provided with a mixed liquid that communicates the mixing cavity 2322 with the outside of the body 232 Inlet 2323, alternatively, in this embodiment, the bottom end of the body 232 is open, and the bottom end of the body 232 adopts the same matching structure as the top cover 231, and a hollow bottom is buc...

Embodiment 2

[0042] Such as Figure 4 as shown, Figure 4 It is a schematic diagram of an MBR membrane aeration device. Based on the same inventive concept, the present invention also provides a MBR membrane aeration device, including a central air delivery pipe 21; several air delivery branch pipes 22, and the gas delivery branch pipes 22 are arranged on the central air delivery pipe 21, the gas delivery branch pipe 22 includes a main pipe 221 and several branch pipes 222. The top of the branch pipe 222 communicates with the main pipe 221. Vertically intersect and communicate with each other on the same horizontal plane, and several gas delivery branch pipes 22 are arranged in parallel; several MBR membrane aerators 23 described in Embodiment 1, the number of MBR membrane aerators 23 corresponds to the number of branch pipes 222 , the bottom end of the branch pipe 222 is connected to the top of the air pipe 233 in the MBR membrane aerator 23. In this embodiment, the bottom end of the bra...

Embodiment 3

[0046] Such as Figure 5 as shown, Figure 5 It is MBR membrane sewage treatment equipment, based on the same inventive concept, the present invention also provides a kind of MBR membrane sewage treatment equipment, including fan 1, the MBR membrane aeration device 2 described in Embodiment 2, membrane pool 3 and MBR membrane module 4. The air outlet of the fan 1 is connected to the air inlet of the central air pipe 21 , the MBR membrane module 4 is set in the membrane tank 3 , and the MBR membrane aeration device 2 is set in the lower part of the MBR membrane module 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com