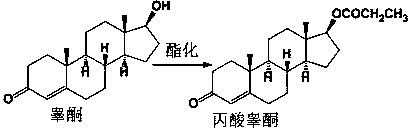

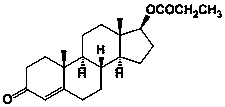

Clean production and preparation method of testosterone propionate

A technology of testosterone propionate and clean production, which is applied in the field of clean production and preparation of testosterone propionate, which can solve the problems of large amount of waste acid water, low purity of testosterone propionate, and high processing cost, so as to reduce recycling and realize clean production , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add 60g of propionic acid and 10g of testosterone into the reaction bottle, stir well, add 3g of propionyl chloride, heat up to reflux for 3 hours, monitor by TLC, the reaction is complete; add 600g of water into the beaker, stir the reaction solution in the reaction bottle slowly Add dropwise into water, stir evenly, filter with suction, wash the material with 200g of water until the pH is 6, drain and discharge the material, dry to obtain 11.7g of testosterone propionate crude product, and collect a total of 850g of waste acid water at the same time;

[0025] (2) Add 117g of methanol, 0.351g of activated carbon, and 11.7g of crude testosterone propionate into the reaction flask, heat up and reflux for decolorization for 1 hour, filter with suction, concentrate the filtrate to the remaining 11.7g of methanol, cool down to 5°C, stir and crystallize for 4 hours, and vacuum filter , drained and discharged, dried at 60°C to constant weight to obtain 11.3g of testosteron...

Embodiment 2

[0028] (1) Add 80g of propionic acid and 10g of testosterone into the reaction bottle, stir well, add 5g of propionyl chloride, heat up to reflux for 2 hours, monitor by TLC, the reaction is complete; add 800g of water into the beaker, stir the reaction solution in the reaction bottle slowly Add dropwise into water, stir evenly, filter with suction, wash the material with 300g of water until the pH is 7, drain and discharge the material, and dry to obtain 11.5g of testosterone propionate crude product, while collecting a total of 1170g of waste acid water;

[0029] (2) Add 138g of methanol, 0.575g of activated carbon, and 11.5g of crude testosterone propionate into the reaction flask, heat up and reflux for decolorization for 0.5h, filter with suction, concentrate the filtrate to the remaining 17.25g of methanol, cool down to 0°C, stir and crystallize for 2h, filter , drained and discharged, dried at 65°C to constant weight to obtain 11.2g of testosterone propionate with a puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com