Black-display multilayer polymer film, preparation method therefor and application of black-display multilayer polymer film

A polymer film, polymerization method technology, applied in the production of bulk chemicals, etc., can solve the problems of poor electrochromic performance, slow response speed, low optical contrast, etc., achieve fast response time, high optical contrast, excellent electrochromic The effect of color changing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

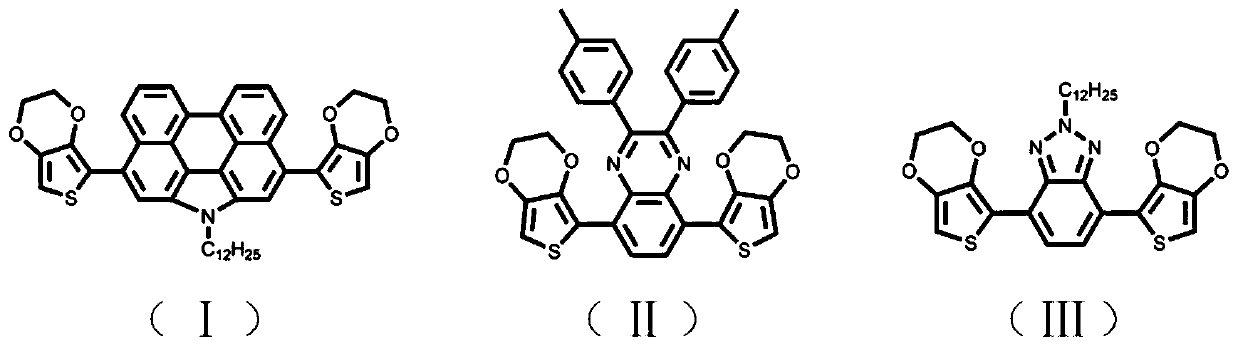

[0029] The molecular structure of the polymeric precursor used is as figure 1 shown. The prepared monomer solutions (I), (II), and (III) have a concentration of 1mg / ml, a supporting electrolyte of 0.1M tetrabutylammonium hexafluorophosphate, and an electrolytic solvent of a mixed solvent of dichloromethane and acetonitrile. The ratio is (3 / 2). Preparation of multi-layer polymer film: First, using cyclic voltammetry polymerization method, the polymerization conditions are: the voltage range is -0.6V ~ 1.1V, the scanning speed is 0.4mV / s, and the number of cycles is 8. In the monomer solution In (I), a red polymer film is electrodeposited; secondly, using the same polymerization method and conditions, in the monomer solution (II), continue to electrodeposit a green polymer film on its surface; finally, continue Using the same polymerization method and conditions, another layer of blue polymer film was electrodeposited in the monomer solution (Ⅲ). Wash the prepared multilayer ...

Embodiment 2

[0031] The molecular structure of the polymeric precursor used is as figure 1 shown. The prepared monomer solutions (I), (II), and (III) have a concentration of 1mg / ml, a supporting electrolyte of 0.1M tetrabutylammonium hexafluorophosphate, and an electrolytic solvent of a mixed solvent of dichloromethane and acetonitrile. The ratio is (3 / 2). Preparation of multi-layer polymer film: first, using cyclic voltammetry polymerization method, the polymerization conditions are: the voltage range is -0.6V ~ 1.1V, the scanning speed is 0.4mV / s, and the number of cycles is 8. In the monomer solution In (I), a layer of red polymer film is electrodeposited; secondly, using the same polymerization method and conditions, in the monomer solution (Ⅲ), continue to electrodeposit a layer of blue polymer film; finally, use the same According to the polymerization method and conditions, a green polymer film is electrodeposited in the monomer solution (II). Wash the prepared multilayer film wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coloring time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com