A kind of anti-salt lubricant for drilling fluid and preparation method thereof

A drilling fluid and lubricant technology, applied in the field of lubricants, can solve problems such as poor salt resistance, achieve low equipment requirements, simple process flow, and good surface lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

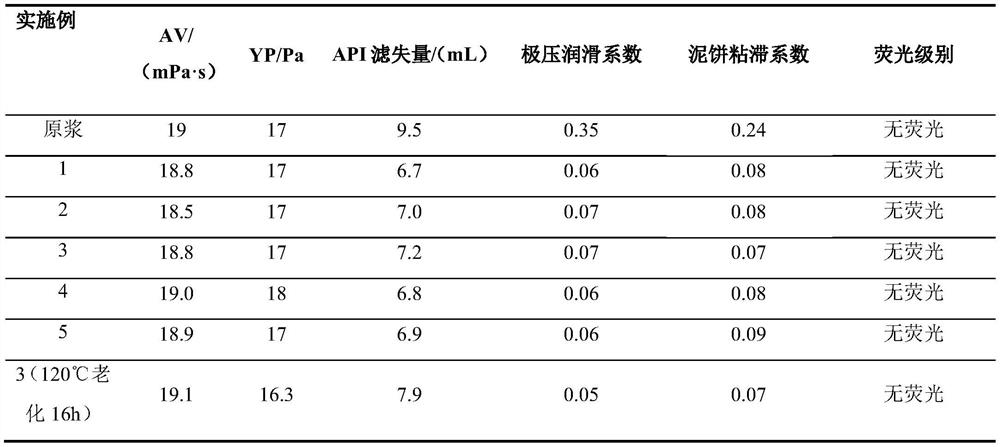

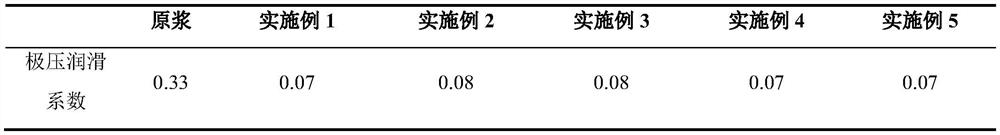

Examples

Embodiment 1

[0035] The anti-salt lubricant for drilling fluid of the present embodiment includes: by weight, 25 parts of biodiesel, 45 parts of modified polysiloxane, 2 parts of Span, 10 parts of lauryl polyvinyl ether, lauryl dextrose 5 parts of glycosides, 5 parts of sodium dodecylbenzenesulfonate, 5 parts of lubricating additives and 130 parts of water.

[0036] The preparation method of the salt-resistant lubricant for drilling fluid of the present embodiment comprises:

[0037] S1: Preparation of modified polysiloxane;

[0038] (1) Add methyldodecyldimethoxysilane and dimethyltetraphenyldisiloxane to water, and add sodium hydroxide, hydrolyze under stirring, wash with water, neutralize and dry Obtain mixed hydrolyzate;

[0039] (2) Mix the mixed hydrolyzate with hexamethyldisiloxane, add chloroplatinic acid, and react at 40°C for 3 hours under the protection of slight nitrogen, then neutralize, wash with water, and distill under reduced pressure to obtain the modified polymer Sili...

Embodiment 2

[0047] The anti-salt lubricant for drilling fluid of the present embodiment includes: 27 parts of biodiesel, 50 parts of modified polysiloxane, 22 parts of Span, 12 parts of polyvinyl lauryl ether, 6 parts of lauryl glucoside, ten parts 6 parts of sodium dialkylbenzene sulfonate, 8 parts of lubricating aid and 140 parts of water.

[0048] The preparation method of the salt-resistant lubricant for drilling fluid of the present embodiment comprises:

[0049] S1: Preparation of modified polysiloxane;

[0050] (1) Add methyldodecyldimethoxysilane and dimethyltetraphenyldisiloxane to water, and add sodium hydroxide, hydrolyze under stirring, wash with water, neutralize and dry Obtain mixed hydrolyzate;

[0051](2) Mix the mixed hydrolyzate with hexamethyldisiloxane, add chloroplatinic acid, and react at 45°C for 5 hours under the protection of slight nitrogen, then neutralize, wash with water, and distill under reduced pressure to obtain the modified polymer Silicone;

[0052] ...

Embodiment 3

[0059] The anti-salt lubricant for drilling fluid of the present embodiment includes: 30 parts of biodiesel, 52 parts of modified polysiloxane, 25 parts of Span, 15 parts of polyvinyl lauryl ether, 7 parts of lauryl glucoside, ten parts 7 parts of sodium dialkylbenzene sulfonate, 10 parts of lubricating aid and 155 parts of water.

[0060] The preparation method of the salt-resistant lubricant for drilling fluid of the present embodiment comprises:

[0061] S1: Preparation of modified polysiloxane;

[0062] (1) Add methyldodecyldimethoxysilane and dimethyltetraphenyldisiloxane to water, and add sodium hydroxide, hydrolyze under stirring, wash with water, neutralize and dry Obtain mixed hydrolyzate;

[0063] (2) Mix the mixed hydrolyzate with hexamethyldisiloxane, add chloroplatinic acid, and react at 60°C for 8 hours under the protection of slight nitrogen, then neutralize, wash with water, and distill under reduced pressure to obtain the modified polymer Silicone;

[0064...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com